Overview of key technologies for mine-wide intelligent video analysis

-

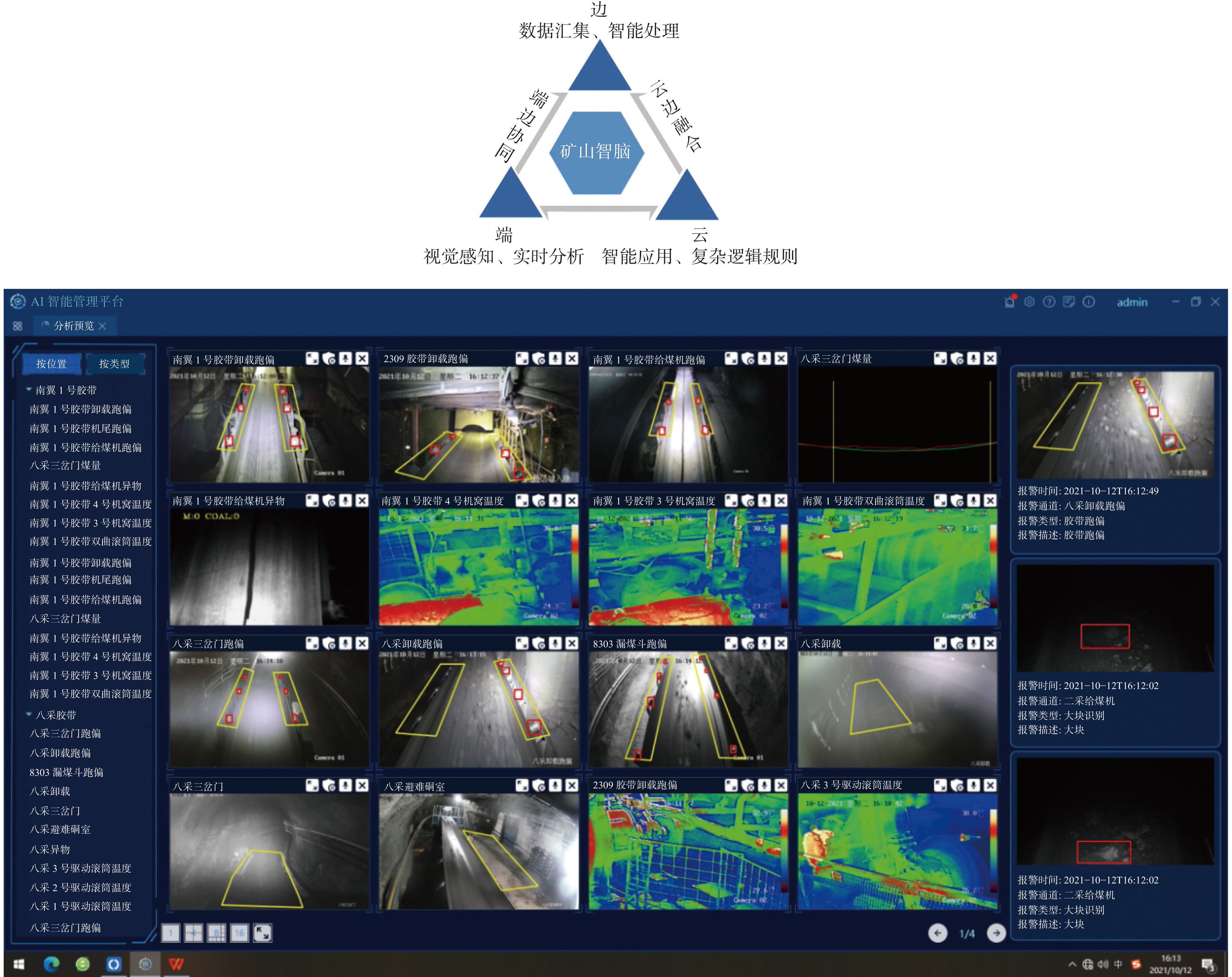

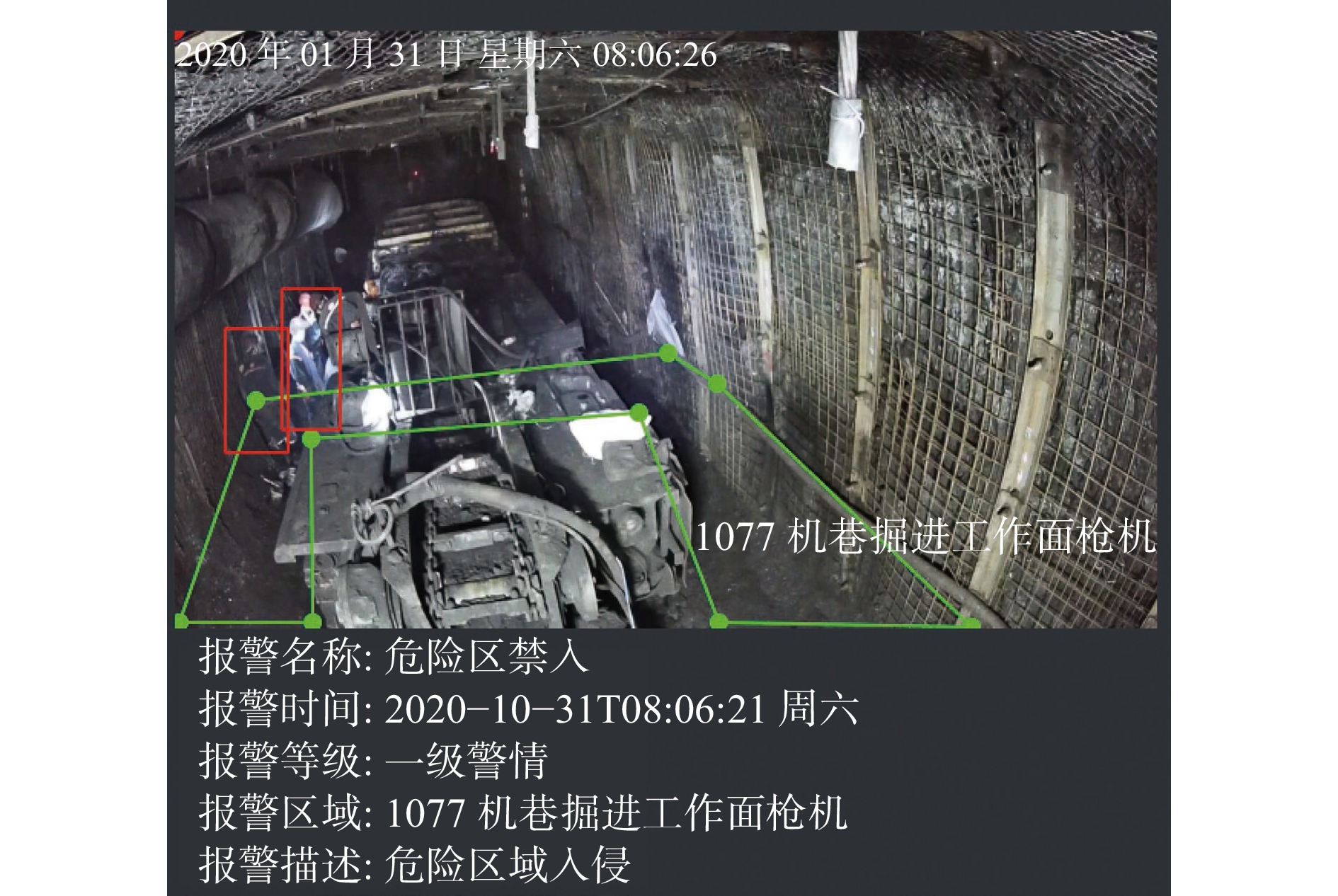

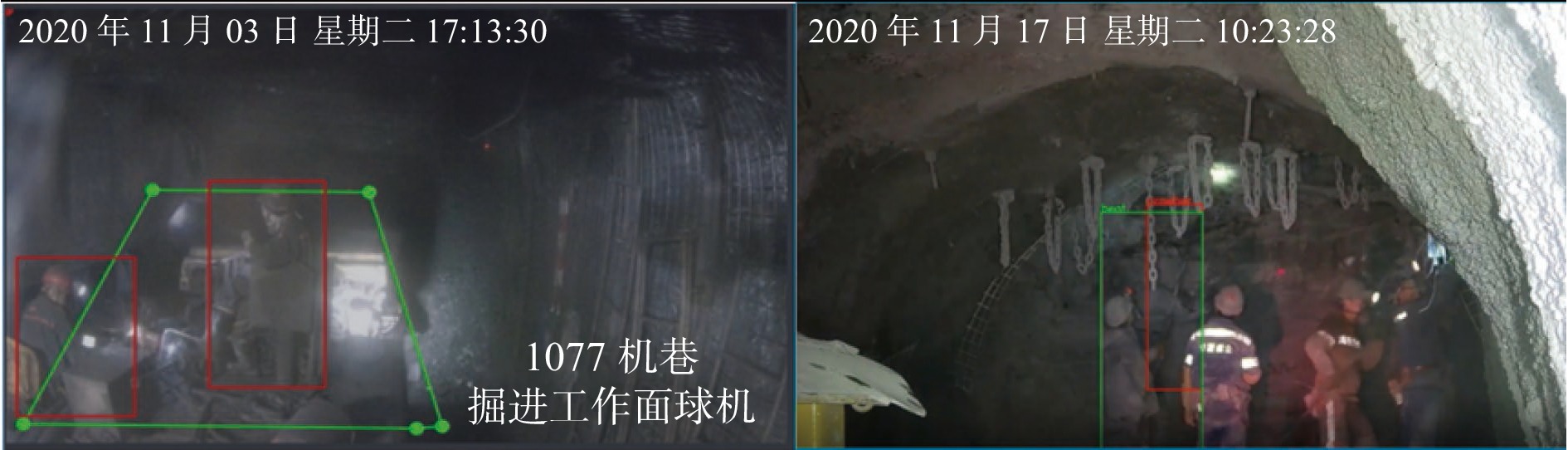

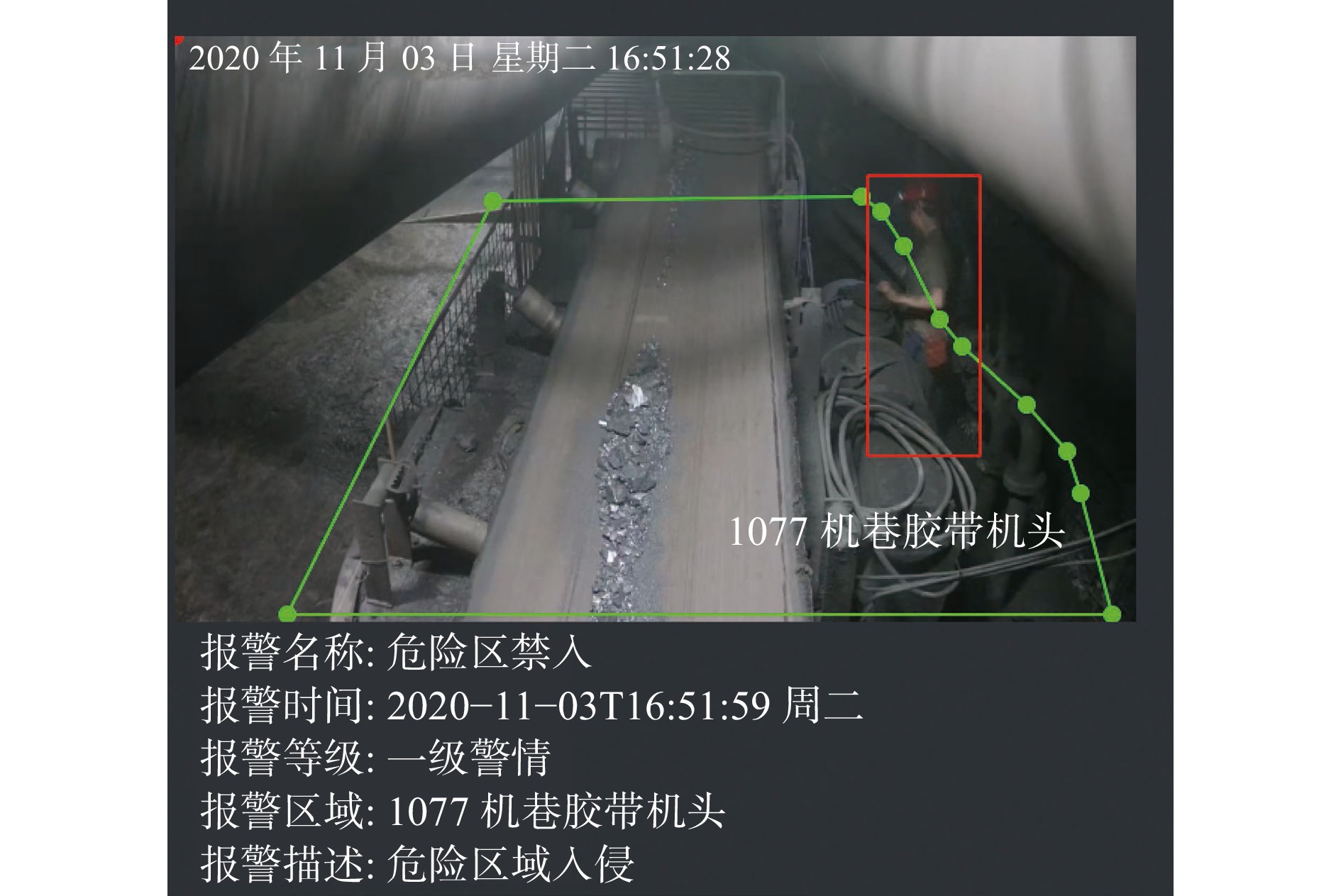

摘要: 智能化是煤矿发展的方向,而智能视频分析是促进煤矿智能化的有效途径。全矿井智能视频分析技术具有实时监控、预警和决策支持能力,有助于提高矿山企业的安全性、生产效率、资源利用效率和环境可持续性。详细介绍了全矿井智能视频分析的关键技术,包括视频采集设备、视频预处理、视频压缩与编码等视频采集与处理技术,目标检测与跟踪、运动检测与分析、物体识别与分类等视频分析基础技术,行为识别与分析、事件检测与警报、视频监控与布防等高级视频分析技术。研发了集成视频识别分析和工业联动控制功能的矿山智脑AI视觉智能服务平台,介绍了智能视频分析技术在智能探放水系统和探放瓦斯系统、煤岩识别与截割系统、掘进工作面、综采工作面、煤流运输系统、矿井提升机系统、辅助运输系统、选煤厂、智能化装车配煤系统等矿井生产场景中的应用。分析指出目前全矿井智能视频分析技术在视频质量、复杂背景、实时性要求、数据隐私和安全、系统可靠性与稳定性等方面仍面临挑战。建议未来加强算法提升和优化、多模态数据融合、实时分析和边缘计算、强化学习和自主决策、数据隐私和安全保护、硬件设备和传感器技术等方面的研究,以全面推动全矿井智能视频分析技术的发展,促进矿山智能化进程。Abstract: Intelligence is the direction of coal mine development, and intelligent video analysis is an effective way to promote coal mine intelligence. The mine-wide intelligent video analysis technology has real-time monitoring, early warning, and decision support capabilities. It helps to improve the safety, production efficiency, resource utilization efficiency, and environmental sustainability of mining enterprises. The key technologies of mine-wide intelligent video analysis are introduced in detail, including video acquisition and processing technologies such as video acquisition equipment, video pre-processing, video compression and coding, basic video analysis technologies such as object detection and tracking, motion detection and analysis, object recognition and classification, and advanced video analysis technologies such as behaviour recognition and analysis, event detection and alarm, video monitoring and arming. A mining intelligent AI visual intelligence service platform that integrates video recognition analysis and industrial linkage control functions is developed. The paper introduces the application of intelligent video analysis technology in mining production scenarios such as intelligent water and gas exploration and discharge systems, coal rock recognition and cutting systems, heading working faces, fully mechanized working faces, coal flow transportation systems, mine hoist systems, auxiliary transportation systems, coal preparation plants, and intelligent loading and coal blending systems. The analysis points out that the current mine-wide intelligent video analysis technology still faces challenges in terms of video quality, complex backgrounds, real-time requirements, data privacy and security, system reliability and stability, etc. It is suggested to strengthen the research on algorithm improvement and optimization, multimodal data fusion, real-time analysis and edge computing, enhanced learning and independent decision-making, data privacy and security protection, hardware equipment and sensor technology in the future. Therefore, the development of mine-wide intelligent video analysis technology is comprehensively promoted and promote the process of mine intelligence is promoted.

-

0. 引言

5G,5.5G,WiFi6,WiFi7,UWB,ZigBee等矿井移动通信系统和车辆及人员定位系统等发射的大功率无线电波,被能作为接收天线的金属结构吸收,并产生放电火花,有点燃爆炸性气体的风险[1-6]。因此,需要合理设置无线电发射器的无线电波防爆安全发射功率阈值,限制无线电发射器的无线电波最大发射功率。现行国家标准GB/T 3836.1—2021《爆炸性环境 第1部分:设备 通用要求》[7]规定无线电发射器的阈功率不得大于6 W。

许多学者认为6 W这一阈值限定得过低,导致通信基站的无线覆盖半径较小[8-10],增大了系统建设成本和维护工作量,不利于矿井移动通信系统和车辆及人员定位系统等在煤矿井下应用。文献[11-12]对国家标准GB/T 3836.1—2021进行了溯源分析,指出国家标准GB/T 3836.1—2021和国际标准IEC 60079-0:2017《Explosive atmospheres-Part 0:Equipment-General requirements》[13]直接引用欧洲标准CLC/TR 50427:2004《Assessment of inadvertent ignition of flammable atmospheres by radio-frequency radiation-Guide》[14]的相关内容,但错误地将无线电波防爆安全功率阈值直接修改为6 W,并提出无线电波防爆安全功率阈值应为8 W。文献[15]指出国家标准GB/T 3836.1—2021和国际标准IEC 60079-0:2017中规定的无线电波防爆安全功率阈值应为接收点火功率阈值,且无线电波防爆安全接收点火功率应为8 W。文献[16]分析了无线电波发射功率、接收总功率和接收点火功率之间的关系,得出无线电波防爆安全发射功率阈值应是无线电波防爆安全接收点火功率阈值的2倍以上,提出煤矿井下无线电波防爆安全发射功率阈值应大于16 W。文献[17]通过搭建谐振耦合系统仿真了无线电波频率为3.55 GHz、收发天线均为单环线圈的情形,结果表明,在无线电波发射功率为100 W时,无法在断点间距为0.4 mm的单环接收线圈中产生击穿放电。文献[18-19]使用基于半波偶极子天线设计的射频电磁能防爆专用试验装置进行试验,结果表明,当发射射频信号为700 MHz正弦波时,测得未点燃瓦斯的临界情况下最小正向功率为49.6 W、馈入最小功率为24.8 W,认为700 MHz频段的无线电波防爆安全发射功率阈值可以提高到20 W以上,并指出了国家标准GB/T 3836.1—2021中发射阈功率6 W的限制来自于20世纪80年代英国的研究成果所存在的不足。文献[20]将能作为接收天线的金属结构等效为单环接收线圈,以多物理场仿真得到的工作频率为3.55 GHz时最小击穿电压为200 V为依据,使用电磁仿真软件模拟了发射天线为八木天线、无线电波频率为3.55 GHz时在单环接收线圈断点两端产生的电压,结果表明,在八木天线近场区、远场区和没有传输损耗时无线电波防爆安全发射功率阈值分别为450,7 200,100 W,但仅考虑了无线电波频率为3.55 GHz时产生击穿放电的特定情形。文献[21]以GB/T 3836.1—2021中规定可能堆积煤尘的电气设备表面温度不能超过150 ℃为依据,使用电磁仿真软件模拟了无线电波在电气设备表面产生的热效应,结果表明,在无线电波发射功率不大于16.48 W时,不会导致电气设备表面温度超过150 ℃。文献[22]依据GB/T 3836.4—2021《爆炸性环境 第4部分:由本质安全型“i”保护的设备》[23]中规定的点燃甲烷–空气混合气体的最小能量为525 μJ,在不同无线电波发射功率下进行电磁仿真,结果表明,在安全距离为0.2 m时,点燃甲烷−空气混合气体的无线电波最小发射功率为27.45 W。

综上所述,仅笔者研究团队[11-12,15-16]对国家标准GB/T 3836.1—2021进行了溯源分析,指出了国家标准GB/T 3836.1—2021和国际标准IEC 60079-0:2017错误地将欧洲标准CLC/TR 50427:2004中规定的接收点火功率8 W直接修改为发射阈功率6 W,提出了无线电波防爆安全发射功率阈值应大于16 W。而其他文献均是通过电磁仿真或试验来验证国家标准GB/T 3836.1—2021中的无线电发射器的阈功率不得大于6 W这一条款限定得过低,均没有指出国家标准GB/T 3836.1—2021和国际标准IEC 60079-0:2017的相关错误。

国家标准GB/T 3836.1—2021和国际标准IEC 60079-0:2017规定无线电发射器的阈功率为无线电发射器的有效输出功率与天线增益的乘积。也就是说,无线电波防爆安全发射功率阈值,不但与无线电发射器的有效输出功率有关,还与天线增益有关。在无线电波防爆安全发射功率阈值一定的条件下,天线增益越大,无线电发射器的有效输出功率就越小。这将限制通过增大天线增益,提高无线传输距离。因此,有必要对国家标准GB/T 3836.1—2021和国际标准IEC 60079-0:2017中规定的阈功率的正确性进行研究,提出合理的无线电波发射功率防爆要求与检测方法。

1. 天线增益

无线电波需要通过天线发射。天线分为无源天线和有源天线:无源天线是一个无源器件;有源天线可以看作是无源天线+有源信号功率放大器。矿井移动通信及人员和车辆定位系统等使用的天线一般为无源天线。因此,下面研究的天线为无源天线。

天线增益是指在输入功率相等的条件下,实际天线在最大辐射方向上与理想全向天线或偶极子天线在空间同一点处所产生的信号功率密度之比,表示天线将射频信号能量向某个特定方向集中辐射的能力。天线为无源器件,自身不会产生能量,更不能增大射频信号的功率和能量。天线增益越大,则在天线最大辐射方向上产生的功率密度越大,但无线电波发射功率不会增大。天线增益可以表示为[24]

$$ {G_{\text{1}}}{\text{ = }}{{{S_{\text{i}}}}}/{{{S_{\text{j}}}}} $$ (1) 式中$ {S_{\text{i}}} $和$ {S_{\text{j}}} $分别为该天线和理想全向天线(或偶极子天线)在相同无线电波发射功率下,且在最大辐射方向上相同接收点处产生的功率密度,W/m2。

天线增益也可以表示为

$$ {G_{\text{2}}}{\text{ = 10lg}}({{{S_{\text{i}}}}}/{{{S_{\text{j}}}}}) $$ (2) 若G2代表相对于理想全向天线的天线增益,单位为dBi;若G2代表相对于偶极子天线的天线增益,单位为dBd。

国家标准GB/T 3836.1—2021和国际标准IEC 60079-0:2017规定阈功率为等效全向辐射功率(Effective Isotropic Radiated Power,EIRP)。若无线电发射器的输出功率Ps为16 W,天线增益G2为3 dBi(即G1为2)时,则EIRP=PsG1=16 W×2=32 W。但EIRP=32 W不是指无线电波发射功率从16 W增大到了32 W,而是代表若天线采用的是理想全向天线,无线电发射器的输出功率需要32 W,才能产生与该天线在最大辐射方向上同样的辐射效果。

2. 天线发射效率

无线电发射器可通过一体化方式与天线直接连接,也可通过射频馈线(含射频电缆)与天线连接。手机和无线便携仪等移动终端的无线电发射器一般采用一体化方式与天线直接连接。具有金属外壳的隔爆型和本质安全型防爆基站(以下简称基站)一般采用外置天线(以下简称天线),其无线电发射器(含隔离电容)通过射频馈线和插接件与天线连接。

基站外壳内的无线电发射器可通过固定在外壳上的插接件与外壳外的天线相连:无线电发射器通过插接件(或直接焊接等)与内部射频馈线连接,内部射频馈线的另一端与外壳上插接件的内部端口连接;天线通过插接件(或直接焊接等)与外部射频馈线连接,外部射频馈线的另一端经插接件与外壳上插接件的外部端口连接,或天线直接通过插接件与外壳上插接件的外部端口连接。

基站外壳内的无线电发射器也可通过穿过电缆引入装置的射频馈线与外壳外的天线相连:无线电发射器通过插接件(或直接焊接等)与穿过电缆引入装置的射频馈线连接,射频馈线的另一端接外部插接件;天线直接通过插接件与射频馈线的外部插接件连接,或天线通过插接件(或直接焊接等)与外部射频馈线连接,外部射频馈线的另一端接插接件,再与射频馈线的外部插接件连接。

为了便于分析,将无线电发射器与外置天线的连接方式简化为无线电发射器经射频馈线(包括插接件)连接天线,如图1所示。

无线电发射器在向外置天线输送射频信号时,会在射频馈线和插接件上产生损耗(以下统称馈线损耗)。馈线损耗主要由阻抗不匹配产生的回波损耗和损耗电阻产生的热损耗2个部分组成。

无线电发射器经射频馈线和插接件向外置天线输送射频信号时,射频馈线和插接件与天线的阻抗不匹配,会产生回波损耗。天线馈入功率为

$$ P_{\mathrm{k}}=\eta_{\mathrm{a}}\eta_{\mathrm{b}}P_{\mathrm{s}} $$ (3) 式中:$ \eta_{\mathrm{a}} $为馈线传输效率;$ \eta_{\mathrm{b}} $为馈电效率。

天线内阻由辐射电阻和损耗电阻组成。因此,馈入天线的功率并不会全部转换为无线电波发射功率,其中一部分在天线损耗电阻上以热损耗的形式消耗掉。天线发射效率$ \eta_{\mathrm{c}} $用无线电波发射功率与天线馈入功率之比表示:

$$ {\eta _{\mathrm{c}}} = \frac{{{P_{\mathrm{t}}}}}{{{P_{\mathrm{k}}}}} = \frac{{{P_{\mathrm{t}}}}}{{{P_{\mathrm{t}}} + {P_{\mathrm{n}}}}} = \frac{{{R_{\mathrm{t}}}}}{{{R_{\mathrm{t}}} + {R_{\mathrm{n}}}}} $$ (4) 式中:${P_{\mathrm{t}}}$为无线电波发射功率,W;${P_{\mathrm{n}}}$为天线损耗电阻消耗的功率,W;${R_{\mathrm{t}}}$为天线的辐射电阻,$\Omega $;${R_{\mathrm{n}}}$为天线损耗电阻,$\Omega $。

因此,无线电波发射功率可表示为

$$ {P_{\mathrm{t}}} = {\eta _{\mathrm{a}}}{\eta _{\mathrm{b}}}{\eta _{\mathrm{c}}}{P_{\mathrm{s}}} $$ (5) 只有在没有馈线损耗、天线回波损耗和天线热损耗的理想情况下,即馈线传输效率${\eta _{\mathrm{a}}}$、天线馈电效率${\eta _{\mathrm{b}}}$和天线发射效率${\eta _{\mathrm{c}}}$均为1时,无线电发射器的输出功率才能全部转换为无线电波发射功率。但在实际工程中,馈线传输效率${\eta _{\mathrm{a}}}$、天线馈电效率${\eta _{\mathrm{b}}}$和天线发射效率${\eta _{\mathrm{c}}}$均小于1。因此,无线电波发射功率小于无线电发射器输出功率。

3. 无线电波防爆安全发射功率及检测方法

3.1 无线电波防爆安全发射功率

在气体浓度、温度、气压、湿度和点火材质等条件一定的情况下,引爆甲烷等可燃性气体的主要因素是火源的能量;对于电火花,主要是电火花能量和功率。上面分析表明,天线不但不能产生能量,不能提升功率,还消耗了能量,降低了功率;无线电波防爆安全发射功率与天线增益无关。因此,国家标准GB/T 3836.1—2021和国际标准IEC 60079-0:2017规定无线电发射器的阈功率为无线电发射器的有效输出功率与天线增益的乘积,是错误的。国家标准GB/T 3836.1—2021和国际标准IEC 60079-0:2017没有正确理解天线增益的含义,错误地认为,天线增益就是功率放大。

天线的损耗电阻是客观存在的,不可避免。天线不但不会增大无线电波发射功率,还会减小无线电波发射功率。因此,无线电波防爆安全发射功率阈值与天线增益无关。煤矿井下无线电波防爆安全发射功率阈值应大于16 W[16],且与天线增益无关。国家标准GB/T 3836.1—2021和国际标准IEC 60079-0:2017规定阈功率不得大于6 W,且与天线增益相关,是完全错误的。

3.2 无线电波防爆安全性能检测方法

为保证无线电发射器的防爆安全性能,需对无线电发射器的无线电波最大发射功率进行检测。通过前面的分析可知,无线电波发射功率小于无线电发射器输出功率。因此,本文提出了无线电波防爆安全性能检测方法——检测无线电发射器输出功率。这既可保证通过检测的防爆无线电设备的防爆安全,又简化了检测方法,更提高了防爆无线电设备的无线电波发射功率,解除了对天线增益的限制,将大大提高煤矿井下防爆无线电设备的无线传输距离。

4. 结论

1) 笔者研究团队对国家标准GB/T 3836.1—2021进行了溯源分析,指出了国家标准GB/T 3836.1—2021和国际标准IEC 60079-0:2017错误地将欧洲标准CLC/TR 50427:2004中规定的接收点火功率8 W直接修改为发射阈功率6 W,提出了无线电波防爆安全发射功率阈值应大于16 W。其他文献均没有指出国家标准GB/T 3836.1—2021和国际标准IEC 60079-0:2017的相关错误。

2) 天线不但不能产生能量,不能提升功率,还消耗了能量,降低了功率;无线电波防爆安全发射功率与天线增益无关。国家标准GB/T 3836.1—2021和国际标准IEC 60079-0:2017规定无线电发射器的阈功率为无线电发射器的有效输出功率与天线增益的乘积,是错误的。国家标准GB/T 3836.1—2021和国际标准IEC 60079-0:2017没有正确理解天线增益的含义,错误地认为,天线增益就是功率放大。

3) 煤矿井下无线电波防爆安全发射功率阈值应大于16 W,且与天线增益无关。国家标准GB/T 3836.1—2021和国际标准IEC 60079-0:2017规定阈功率(无线电发射器的有效输出功率与天线增益的乘积)不得大于6 W,且与天线增益相关,是完全错误的。

4) 无线电波发射功率小于无线电发射器输出功率。因此,进行无线电波防爆安全性能检测时,仅检测无线电发射器输出功率。这既可保证通过检测的防爆无线电设备的防爆安全,又简化了检测方法,更提高了防爆无线电设备的无线电波发射功率,解除了对天线增益的限制,将大大提高煤矿井下防爆无线电设备的无线传输距离。

【编者按】全矿井智能视频分析技术是保障我国煤矿智能化建设和煤炭工业高质量发展的核心技术支撑。在矿井受限空间中,巷道空间结构复杂、电磁环境干扰强、人造光源照明不均匀、采掘运工作面粉尘及水雾大等环境因素,导致图像的成像质量较差、场景的高清重建困难、目标检测与识别精度不高等问题,严重制约矿井AI视频识别系统的智能化、精准化应用。为推动人工智能和计算机视觉驱动的智能视频分析技术在煤矿安全生产中的应用,促进学术交流,《工矿自动化》编辑部特邀中国矿业大学程德强教授为客座主编,中国矿业大学陈伟教授、煤炭科学技术研究院有限公司孟庆勇研究员为客座副主编,于2023年第11期策划出版“全矿井智能视频分析技术”专刊。在专刊出版之际,衷心感谢各位专家学者为专刊撰稿!感谢中国矿业大学、中国矿业大学(北京)、西安科技大学、中煤科工集团常州研究院有限公司、煤炭科学技术研究院有限公司等单位给予专刊组织过程中的大力支持! -

-

[1] 王国法,杜毅博. 智慧煤矿与智能化开采技术的发展方向[J]. 煤炭科学技术,2019,47(1):1-10. WANG Guofa,DU Yibo. Development direction of intelligent coal mine and intelligent mining technology[J]. Coal Science and Technology,2019,47(1):1-10.

[2] 王国法,赵国瑞,任怀伟. 智慧煤矿与智能化开采关键核心技术分析[J]. 煤炭学报,2019,44(1):34-41. WANG Guofa,ZHAO Guorui,REN Huaiwei. Analysis on key technologies of intelligent coal mine and intelligent mining[J]. Journal of China Coal Society,2019,44(1):34-41.

[3] 刘峰,曹文君,张建明,等. 我国煤炭工业科技创新进展及“十四五”发展方向[J]. 煤炭学报,2021,46(1):1-15. LIU Feng,CAO Wenjun,ZHANG Jianming,et al. Current technological innovation and development direction of the 14(th) Five-Year Plan period in China coal industry[J]. Journal of China Coal Society,2021,46(1):1-15.

[4] LALATENDU M,DEVI P M,PRASANTA K J. Application of wireless sensor network for environmental monitoring in underground coal mines:A systematic review[J]. Journal of Network and Computer Applications,2018,106:48-67. DOI: 10.1016/j.jnca.2017.12.022

[5] 刘峰,曹文君,张建明. 持续创新70年硕果丰盈——煤炭工业70年科技创新综述[J]. 中国煤炭,2019,45(9):5-12. LIU Feng,CAO Wenjun,ZHANG Jianming. 70 years of continuous innovation and fruitfulness-an overview of 70 years of scientific and technological innovation in the coal industry[J]. Journal of China Coal,2019,45(9):5-12.

[6] 王国法,刘峰,庞义辉,等. 煤矿智能化——煤炭工业高质量发展的核心技术支撑[J]. 煤炭学报,2019,44(2):349-357. WANG Guofa,LIU Feng,PANG Yihui,et al. Coal mine intellectualization:the core technology of high quality development[J]. Journal of China Coal Society,2019,44(2):349-357.

[7] 姜德义,魏立科,王翀,等. 智慧矿山边缘云协同计算技术架构与基础保障关键技术探讨[J]. 煤炭学报,2020,45(1):484-492. JIANG Deyi,WEI Like,WANG Chong,et al. Discussion on the technology architecture and key basic support technology for intelligent mine edge-cloud collaborative computing[J]. Journal of China Coal Society,2020,45(1):484-492.

[8] YAO Haifei,WANG Haiyan,LI Yanchuan,et al. Three-dimensional spatial and temporal distributions of dust in roadway tunneling[J]. International Journal of Mining Science and Technology,2020,7(1):88-96.

[9] LECCA M. STAR:a segmentation-based approximation of point-based sampling milano retinex for color image enhancement[J]. IEEE Transactions on Image Processing,2018,27(12):5802-5812. DOI: 10.1109/TIP.2018.2858541

[10] 蔡文郁,张美燕,吴岩,等. 基于循环生成对抗网络的超分辨率重建算法研究[J]. 电子与信息学报,2022,44(1):178-186. CAI Wenyu,ZHANG Meiyan,WU Yan,et al. Research on cyclic generation countermeasure network based super-resolution image reconstruction algorithm[J]. Journal of Electronics & Information Technology,2022,44(1):178-186.

[11] WANG Jinbao,LU Ke,XUE Jian,et al. Single image dehazing based on the physical model and MSRCR algorithm[J]. IEEE Transactions on Circuits and Systems for Video Technology,2018,28(9):2190-2199. DOI: 10.1109/TCSVT.2017.2728822

[12] 张立亚,郝博南,孟庆勇,等. 基于HSV空间改进融合Retinex算法的井下图像增强方法[J]. 煤炭学报,2020,45(增刊1):532-540. ZHANG Liya,HAO Bonan,MENG Qingyong,et al. Method of image enhancement in coal mine based on improved Retinex fusion algorithm in HSV space[J]. Journal of China Coal Society,2020,45(S1):532-540.

[13] JIANG He,YANG Jie. In-place similarity and its applications in image and video detail enhancement[J]. Electronics Letters,2016,52(12):1022-1024. DOI: 10.1049/el.2015.3876

[14] 张谢华,张申,方帅,等. 煤矿智能视频监控中雾尘图像的清晰化研究[J]. 煤炭学报,2014,39(1):198-204. ZHANG Xiehua,ZHANG Shen,FANG Shuai,et al. Clearing research on fog and dust images in coalmine intelligent video surveillance[J]. Journal of China Coal Society,2014,39(1):198-204.

[15] 应东杰,李文节. 煤矿监控图像增强算法的分析与实现[J]. 工矿自动化,2012,38(8):55-58. YING Dongjie,LI Wenjie. Analysis of enhancement algorithms of coal mine monitoring image and its realization[J]. Industry and Mine Automation,2012,38(8):55-58.

[16] 程德强,郑珍,姜海龙. 一种煤矿井下图像增强算法[J]. 工矿自动化,2015,41(12):31-34. CHENG Deqiang,ZHENG Zhen,JIANG Hailong. An image enhancement algorithm for coal mine underground[J]. Industry and Mine Automation,2015,41(12):31-34.

[17] 范伟强,刘毅. 基于自适应小波变换的煤矿降质图像模糊增强算法[J]. 煤炭学报,2020,45(12):4248-4260. FAN Weiqiang,LIU Yi. Fuzzy enhancement algorithm of coal mine degradation image based on adaptive wavelet transform[J]. Journal of China Coal Society,2020,45(12):4248-4260.

[18] 唐守锋,史可,仝光明,等. 一种矿井低照度图像增强算法[J]. 工矿自动化,2021,47(10):32-36. TANG Shoufeng,SHI Ke,TONG Guangming,et al. A mine low illumination image enhancement algorithm[J]. Industry and Mine Automation,2021,47(10):32-36.

[19] JIANG He,ASAD M,HUANG Xiaolin,et al. Learning in-place residual homogeneity for single image detail enhancement[J]. Journal of Electronic Imaging,2020,29:16-41.

[20] DU Yuxin,TONG Minming,ZHOU Lingling,et al. Edge detection based on Retinex theory and wavelet multiscale product for mine images[J]. Applied Optics,2016,55:9625-9637. DOI: 10.1364/AO.55.009625

[21] WANG Lingfeng,XIANG Shiming,MENG Gaofeng,et al. Edge-directed single-image super-resolution via adaptive gradient magnitude self-interpolation[J]. IEEE Transactions on Circuits and Systems for Video Technology,2013,23(8):1289-1299. DOI: 10.1109/TCSVT.2013.2240915

[22] 汪海涛,于文洁,张光磊. 基于在线多字典学习的矿井图像超分辨率重建方法[J]. 工矿自动化,2020,46(9):74-78. WANG Haitao,YU Wenjie,ZHANG Guanglei. Super-resolution reconstruction method of mine image based on online multi-dictionary learning[J]. Industry and Mine Automation,2020,46(9):74-78.

[23] 程德强,于文洁,郭昕,等. 自适应的图像在线字典学习超分辨率重建算法[J]. 激光与光电子学进展,2020,57(6):302-312. CHENG Deqiang,YU Wenjie,GUO Xin,et al. Super-resolution reconstruction algorithm based on adaptive image online dictionary learning[J]. Laser & Optoelectronics Progress,2020,57(6):302-312.

[24] CAI Huangkai,JIANG He,HUANG Xiaolin,et al. Violence detection based on spatio-temporal feature and fisher vector[C]. Chinese Conference on Pattern Recognition and Computer Vision,Guangzhou,2018:180-190.

[25] REN Chao,HE Xiaohai,TENG Qizhi,et al. Single image super-resolution using local geometric duality and non-local similarity[J]. IEEE Transactions on Image Processing,2016,25(5):2168-2183. DOI: 10.1109/TIP.2016.2542442

[26] JIANG He,ZHAI Guangtao,CAI Huangkai,et al. Scalable motion analysis based surveillance video de-noising[C]. IEEE International Conference on Multimedia & Expo Workshops,San Diego,2018:1-6.

[27] GAO Rui,CHENG Deqiang,YAO Jie,et al. Low-rank representation-based image super-resolution reconstruction with edge-preserving[J]. KSII Transaction on Internet and Information Systems,2020,14(9):3745-3761.

[28] JIANG He,CONG Zaichen,GAO Zhiyong,et al. Image super-resolution with facet improvement and detail enhancement based on local self examples[C]. International Conference on Wireless Communications and Signal Processing,Hangzhou,2013:1-6.

[29] JIANG He,YANG Jie. Optimized image up-scaling from learning selective similarity[C]. International Conference on Neural Information Processing,Guangzhou,2017:467-475.

[30] 程德强,陈亮亮,蔡迎春,等. 边缘融合的多字典超分辨率图像重建算法[J]. 煤炭学报,2018,43(7):2084-2090. CHENG Deqiang,CHEN Liangliang,CAI Yingchun,et al. Image super-resolution reconstruction based on multi-dictionary and edge fusion[J]. Journal of China Coal Society,2018,43(7):2084-2090.

[31] CHEN Liangliang,KOU Qiqi,CHENG Deqiang,et al. Content-guided deep residual network for single image super-resolution[J]. Optik,2020,202. DOI: 10.1016/j.ijleo.2019.163678.

[32] 贾克斌,崔腾鹤,刘鹏宇,等. 基于深层特征学习的高效率视频编码中帧内快速预测算法[J]. 电子与信息学报,2021,43(7):2023-2031. JIA Kebin,CUI Tenghe,LIU Pengyu,et al. Fast prediction algorithm in high efficiency video coding intra-mode based on deep feature learning[J]. Journal of Electronics & Information Technology,2021,43(7):2023-2031.

[33] XU Guoping,LIAO Wentao,ZHANG Xuan,et al. Haar wavelet downsampling:a simple but effective downsampling module for semantic segmentation[J]. Pattern Recognition,2023,143. DOI: 10.1016/j.patcog.2023.109819.

[34] 文学志,方巍,郑钰辉. 一种基于类Haar特征和改进AdaBoost分类器的车辆识别算法[J]. 电子学报,2011,39(5):1121-1126. WEN Xuezhi,FANG Wei,ZHENG Yuhui. An algorithm based on Haar-like features and improved AdaBoost classifier for vehicle recognition[J]. Acta Electronica Sinica,2011,39(5):1121-1126.

[35] 黄威铭,吴焯标,陶铭. 基于HOG和SVM的嵌入式行人检测与追踪系统设计与实现[J]. 物联网技术,2023,13(8):29-32. HUANG Weiming,WU Zhuobiao,TAO Ming. Design and implementation of an embedded pedestrian detection and tracking system based on HOG and SVM[J]. Internet of Things Technologies,2023,13(8):29-32.

[36] 华同兴,邢存恩,赵亮. 基于Faster R−CNN的煤岩识别与煤层定位测量[J]. 矿山机械,2019,47(8):4-9. HUA Tongxing,XING Cun'en,ZHAO Liang. Recognition of coal rock and positioning measurement of coal seam based on Faster R-CNN[J]. Mining & Processing Equipment,2019,47(8):4-9.

[37] REN Shaoqing,HE Kaiming,GIRSHICK R,et al. Faster R-CNN:towards real-time object detection with region proposal networks[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence,2017,39(6). DOI: 10.1109/TPAMI.2016.2577031.

[38] BOCHKOVSKIY A,WANG C Y,LIAO H Y M . YOLOv4:optimal speed and accuracy of object detection[Z]. DOI: 10.48550/arXiv.2004.10934.

[39] 郭永存,杨豚,王爽. 基于改进YOLOv4–Tiny的矿井电机车多目标实时检测[J]. 工程科学与技术,2023,55(5):232-241. GUO Yongcun,YANG Tun,WANG Shuang. Multi-object real-time detection of mine electric locomotive based on improved YOLOv4-Tiny[J]. Advanced Engineering Sciences,2023,55(5):232-241.

[40] LIU Wei,ANGUELOV D,ERHAN D,et al. SSD:single shot multiBox detector[C]. European Conference on Computer Vision,Amsterdam,2016:21-37.

[41] 葛淑伟,张永茜,秦嘉欣,等. 基于优化SSD−MobileNetV2的煤矿井下锚孔检测方法[J]. 采矿与岩层控制工程学报,2023,5(2):66-74. GE Shuwei,ZHANG Yongqian,QIN Jiaxin,et al. Rock bolt borehole detection method for underground coal mines based on optimized SSD-MobileNetV2[J]. Journal of Mining and Strata Control Engineering,2023,5(2):66-74.

[42] 张玉涛,张梦凡,史学强,等. 基于深度学习的井下运动目标跟踪算法研究[J]. 煤炭工程,2022,54(10):151-155. ZHANG Yutao,ZHANG Mengfan,SHI Xueqiang,et al. Object tracking algorithm of moving objects in underground mine based on deep learning[J]. Coal Engineering,2022,54(10):151-155.

[43] 程德强,王雨晨,寇旗旗,等. 基于改进深度残差网络的矿井图像分类[J]. 计算机应用研究,2021,38(5):1576-1580. CHENG Deqiang,WANG Yuchen,KOU Qiqi,et al. Classification of mine images based on improved deep residual network[J]. Application Research of Computers,2021,38(5):1576-1580.

[44] 邵小强,李鑫,杨涛,等. 改进YOLOv5s和DeepSORT的井下人员检测及跟踪算法[J/OL]. 煤炭科学技术:1-12 [2023-08-31]. https://doi.org/10.13199/j.cnki.cst.2022-1933. SHAO Xiaoqiang,LI Xin,YANG Tao,et al. Improving underground personnel eetection and tracking algorithms for YOLOv5s and DeepSORT [J/OL]. Coal Science and Technology:1-12 [2023-08-31]. https://doi.org/10.13199/j.cnki.cst.2022-1933.

[45] JACQUES G,NOURELDIN A,MAHMOUD E,et al. Wellbore surveying while drilling based on Kalman filtering[J]. American Journal of Engineering and Applied Sciences,2010,3(2):240-259. DOI: 10.3844/ajeassp.2010.240.259

[46] 崔丽珍,张清宇,郭倩倩,等. 基于CNN−LSTM的井下人员行为模式识别模型[J]. 无线电工程,2023,53(6):1375-1381. CUI Lizhen,ZHANG Qingyu,GUO Qianqian,et al. Underground personnel behavior pattern recognition model based on CNN-LSTM[J]. Radio Engineering,2023,53(6):1375-1381.

[47] 李尧,桂方俊. 基于EfficientNet和LSTM的井下设备定位技术[J]. 信息记录材料,2023,24(5):121-123,126. LI Yao,GUI Fangjun. Underground equipment positioning technology based on EfficientNet and LSTM[J]. Information Recording Materials,2023,24(5):121-123,126.

[48] 党伟超,张泽杰,白尚旺,等. 基于改进双流法的井下配电室巡检行为识别[J]. 工矿自动化,2020,46(4):75-80. DANG Weichao,ZHANG Zejie,BAI Shangwang,et al. Inspection behavior recognition of underground power distribution room based on improved two-stream CNN method[J]. Industry and Mine Automation,2020,46(4):75-80.

[49] 程德强,刘洁,郭政. 基于分层光流的煤矿井下运动目标跟踪算法[J]. 工矿自动化,2015,41(3):75-79. CHENG Deqiang,LIU Jie,GUO Zheng. An algorithm for moving targets tracking in coal mine underground based on layered optical flow[J]. Industry and Mine Automation,2015,41(3):75-79.

[50] YE Xuehong,XIAO Qingwei. Research on target tracking in coal mine based on optical flow method[C]. International Conference on Graphic and Image Processing,Suzhou,2015:1-6.

[51] 刘江,郭荣春,王燕妮. 基于卡尔曼滤波的高斯混合模型目标检测算法[J]. 探测与控制学报,2022,44(2):79-84. LIU Jiang,GUO Rongchun,WANG Yanni. A gaussian mixture Kalman filter algorithm of target detection[J]. Journal of Detection & Control,2022,44(2):79-84.

[52] 张小艳,郭海涛. 基于改进混合高斯模型的井下目标检测算法[J]. 工矿自动化,2021,47(4):67-72. ZHANG Xiaoyan,GUO Haitao. Underground target detection algorithm based on improved Gaussian mixture model[J]. Industry and Mine Automation,2021,47(4):67-72.

[53] 刘伟,郝晓丽,吕进来. 自适应混合高斯建模的高效运动目标检测[J]. 中国图象图形学报,2020,25(1):113-125. LIU Wei,HAO Xiaoli,LYU Jinlai. Efficient moving targets detection based on adaptive Gaussian mixture modelling[J]. Journal of Image and Graphics,2020,25(1):113-125.

[54] 申柯,陈熙. 增强型局部二值模式及其图像纹理特征提取[J]. 计算机仿真,2023,40(6):260-267,326. SHEN Ke,CHEN Xi. Enhanced local binary pattern and its image texture feature extraction[J]. Computer Simulation,2023,40(6):260-267,326.

[55] JIANG He,GAO Zhiyong,ZHANG Xiaoyun. Image super resolution based on local self examples with nonlocal constraints and enhancement with 2-order holomorphic complete differential kernel[C]. International Conference on Audio,Language and Image Processing,Shanghai,2014:759-764.

[56] 程德强,张皓翔,江曼,等. 融合主曲率与颜色信息的彩色图像检索算法[J]. 计算机辅助设计与图形学学报,2021,33(2):223-231. CHENG Deqiang,ZHANG Haoxiang,JIANG Man,et al. Color image retrieval method fusing principal curvature and color information[J]. Journal of Computer-Aided Design & Computer Graphics,2021,33(2):223-231.

[57] ZHANG Haoxiang,JINAG Man,KOU Qiqi. Color image retrieval algorithm fusing color and principal curvatures information[J]. IEEE Access,2020(8):184945-184954.

[58] 江曼,张皓翔,程德强,等. 融合HSV与方向梯度特征的多尺度图像检索[J]. 光电工程,2021,48(11):64-76. JIANG Man,ZHANG Haoxiang,CHENG Deqiang,et al. Multi-scale image retrieval based on HSV and directional gradient features[J]. Opto-Electronic Engineering,2021,48(11):64-76.

[59] 寇旗旗,程德强,于文洁,等. 一种基于颜色和纹理信息的运动目标识别装置及方法:CN110232703A[P]. 2019-09-13. KOU Qiqi,CHENG Deqiang,YU Wenjie,et al. A moving target recognition device and method based on color and texture information:CN110232703A[P]. 2019-09-13.

[60] XUE Yuting,BAHRAMI D,ZHOU Lihong. Identifying the location and size of an underground mine fire with simulated ventilation data and random forest model[J]. Mining,Metallurgy & Exploration,2023,40(4):1399-1407.

[61] 万航. 煤矿井下视频监控异常行为识别算法的研究[D]. 太原:太原科技大学,2013. WAN Hang. Research on abnormal behavior recognition algorithm for video surveillance in coal mines [D]. Taiyuan:Taiyuan University of Science and Technology,2013.

[62] 李占利,权锦成,靳红梅. 基于3D−Attention与多尺度的矿井人员行为识别算法[J]. 国外电子测量技术,2023,42(7):95-104. LI Zhanli,QUAN Jincheng,JIN Hongmei. Mine personnel behavior recognition algorithm based on 3D-Attention and multi-scale[J]. Foreign Electronic Measurement Technology,2023,42(7):95-104.

[63] 游青山,冉霞. 基于机器视觉的矿井作业人员行为监测及违章识别系统[J]. 自动化与信息工程,2021,42(4):20-24. YOU Qingshan,RAN Xia. Behavior monitoring and violation recognition system of mine operators based on machine vision[J]. Automation & Information Engineering,2021,42(4):20-24.

[64] 张立亚. 基于动目标特征提取的矿井目标监测[J]. 煤炭学报,2017,42(增刊2):603-610. ZHANG Liya. Mine target monitoring based on dynamic target feature extraction[J]. Journal of China Coal Society,2017,42(S2):603-610.

[65] 崔丽珍,吴迪,赫佳星,等. 基于改进粒子滤波的井下跟踪算法研究与实现[J]. 计算机应用研究,2017,34(5):1476-1479. CUI Lizhen,WU Di,HE Jiaxing,et al. Research and implementation on underground tracking algorithm based on improved particle filter[J]. Application Research of Computers,2017,34(5):1476-1479.

[66] 张瑞,李其申,储珺. 基于3D卷积神经网络的人体动作识别算法[J]. 计算机工程,2019,45(1):259-263. ZHANG Rui,LI Qishen,CHU Jun. Human action recognition algorithm based on 3D convolution neural network[J]. Computer Engineering,2019,45(1):259-263.

[67] 魏英姿,曹振林. 安防视频行人异常徘徊提示的决策树方法[J]. 物联网技术,2023,13(6):28-32. WEI Yingzi,CAO Zhenlin. Decision tree method for warning pedestrian abnormal wandering in security video[J]. Internet of Things Technology,2023,13(6):28-32.

[68] 刘西想. 基于机器视觉的矿井下异常行为识别研究[D]. 徐州:中国矿业大学,2021. LIU Xixiang. Research on recognition of abnormal behavior in underground mine based on machine vision[D]. Xuzhou:China University of Mining and Technology,2021.

[69] 姜珊. 基于深度学习的行为异常检测[J]. 信息技术与信息化,2021(2):216-217. JIANG Shan. Behavioral anomaly detection based on deep learning[J]. Information Technology and Informatization,2021(2):216-217.

[70] 程德强,徐进洋,寇旗旗,等. 融合残差信息轻量级网络的运煤皮带异物分类[J]. 煤炭学报,2022,47(3):1361-1369. CHENG Deqiang,XU Jinyang,KOU Qiqi,et al. Lightweight network based on residual information for foreign body classification on coal conveyor belt[J]. Journal of China Coal Society,2022,47(3):1361-1369.

[71] 黄瀚,程小舟,云霄,等. 基于DA−GCN的煤矿人员行为识别方法[J]. 工矿自动化,2021,47(4):62-66. HUANG Han,CHENG Xiaozhou,YUN Xiao,et al. DA-GCN-based coal mine personnel action recognition method[J]. Industry and Mine Automation,2021,47(4):62-66.

[72] ASAD M,JIANG He,YANG Jie,et al. Multi-level two-stream fusion-based spatio-temporal attention model for violence detection and localization[J]. International Journal of Pattern Recognition and Artificial Intelligence,2022,36(1). DOI:10.1142/ S0218001422550023.

[73] ASAD M J,JIANG He,YANG Jie,et al. Multi-stream 3D latent feature clustering for abnormality detection in videos[J]. Applied Intelligence,2021,52:1126-1143.

[74] 王伟峰,张宝宝,王志强,等. 基于YOLOv5的矿井火灾视频图像智能识别方法[J]. 工矿自动化,2021,47(9):53-57. WANG Weifeng,ZHANG Baobao,WANG Zhiqiang,et al. Intelligent identification method of mine fire video images based on YOLOv5[J]. Industry and Mine Automation,2021,47(9):53-57.

[75] YANG Jianping,PENG Jianlin,LI Yida,et al. Gangue localization and volume measurement based on adaptive deep feature fusion and surface curvature filter[J]. IEEE Transactions on Instrumentation and Measurement,2021,70:1-13.

[76] 许鹏. 基于边缘计算的煤矿井下皮带异物检测关键技术研究[D]. 徐州:中国矿业大学,2021. XU Peng. Study on the key technology of foreign object detection of coal mine belt based on edge computing[D]. Xuzhou:China University of Mining and Technology,2021.

[77] 胡璟皓. 基于深度学习的带式输送机非煤异物视频检测系统[D]. 太原:太原理工大学,2021. HU Jinghao. Video monitoring system for non-coal foreign matter of belt conveyor based on deep learning[D]. Taiyuan:Taiyuan University of Technology,2021.

[78] 程德强,郭昕,陈亮亮,等. 多通道递归残差网络的图像超分辨率重建[J]. 中国图象图形学报,2021,26(3):605-618. CHENG Deqiang,GUO Xin,CHEN Liangliang,et al. Image super-resolution reconstruction from multi-channel recursive residual network[J]. Journal of Image and Graphics,2021,26(3):605-618.

[79] 郝帅,张旭,马旭,等. 基于CBAM−YOLOv5的煤矿输送带异物检测[J]. 煤炭学报,2022,47(11):4147-4156. HAO Shuai,ZHANG Xu,MA Xu,et al. Foreign object detection in coal mine conveyor belt based on CBAM-YOLOv5[J]. Journal of China Coal Society,2022,47(11):4147-4156.

[80] 刘浩,刘海滨,孙宇,等. 煤矿井下员工不安全行为智能识别系统[J]. 煤炭学报,2021,46(增刊2):1159-1169. LIU Hao,LIU Haibin,SUN Yu,et al. Intelligent recognition system of unsafe behavior of underground coal miners[J]. Journal of China Coal Society,2021,46(S2):1159-1169.

[81] 张立亚. 矿山智能视频分析与预警系统研究[J]. 工矿自动化,2017,43(11):16-20. ZHANG Liya. Research on intelligent video analysis and early warning system for mine[J]. Industry and Mine Automation,2017,43(11):16-20.

[82] 屈世甲,武福生. 基于边缘计算的采煤工作面甲烷监测模式研究[J]. 煤炭科学技术,2020,48(12):161-167. QU Shijia,WU Fusheng. Research on methane monitoring mode of coal mining face based on edge computing[J]. Coal Science and Technology,2020,48(12):161-167.

[83] HESCOCK J,NEWMAN C,AGIOUTANTIS Z. Development of a new algorithm for implementing the edge effect offset for subsidence calculations[J]. International Journal of Mining Science and Technology,2018,28(1):61-66. DOI: 10.1016/j.ijmst.2017.11.010

[84] 朱晓娟,张浩. 智慧煤矿中边缘计算任务分配研究[J]. 工矿自动化,2021,47(6):32-39. ZHU Xiaojuan,ZHANG Hao. Research on task allocation of edge computing in intelligent coal mine[J]. Industry and Mine Automation,2021,47(6):32-39.

[85] 李敬兆,秦晓伟,汪磊. 基于边云协同框架的煤矿井下实时视频处理系统[J]. 工矿自动化,2021,47(12):1-7. LI Jingzhao,QIN Xiaowei,WANG Lei. Real-time video processing system in coal mine based on edge-cloud collaborative framework[J]. Industry and Mine Automation,2021,47(12):1-7.

[86] 屈世甲,武福生,贺耀宜. 边缘计算模式在煤矿监测监控体系中的应用[J]. 煤炭科学技术,2021,50(5):1-8. QU Shijia,WU Fusheng,HE Yaoyi. Application of edge computing mode in coal mine monitoring and control system[J]. Coal Science and Technology,2021,50(5):1-8.

[87] 牟琦,韩嘉嘉,张寒,等. 基于云边协同的煤矿井下尺度自适应目标跟踪方法[J]. 工矿自动化,2023,49(4):50-61. MU Qi,HAN Jiajia,ZHANG Han,et al. A scale-adaptive target tracking method for coal mine underground based on cloud-edge collaboration[J]. Journal of Mine Automation,2023,49(4):50-61.

[88] 程德强,钱建生,郭星歌,等. 煤矿安全生产视频AI识别关键技术研究综述[J]. 煤炭科学技术,2023,51(2):349-365. CHENG Deqiang,QIAN Jiansheng,GUO Xingge,et al. Review on key technologies of AI recognition for videos in coal mine[J]. Coal Science and Technology,2023,51(2):349-365.

-

期刊类型引用(2)

1. 孙继平,彭铭. 室内电磁波传播衰减统计模型用于矿井的适用性研究. 工矿自动化. 2025(02): 1-8 .  本站查看

本站查看

2. 孙继平,彭铭,刘斌. 矿井无线传输测试分析与矿用5G优选工作频段研究. 工矿自动化. 2024(10): 1-11+20 .  本站查看

本站查看

其他类型引用(0)

下载:

下载: