Factors influencing the dust-blocking effect of air curtains during the fully mechanized excavation of working faces

-

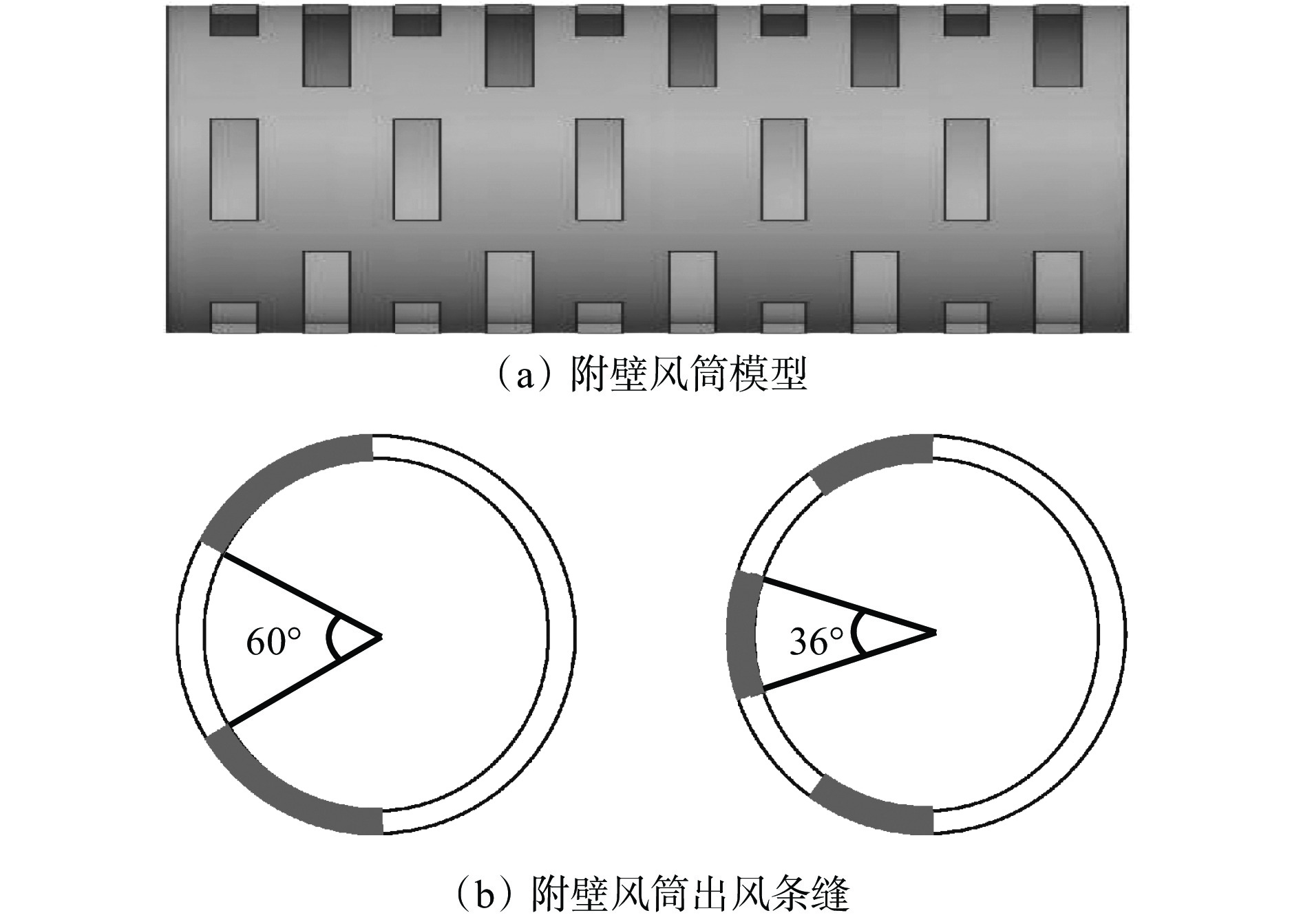

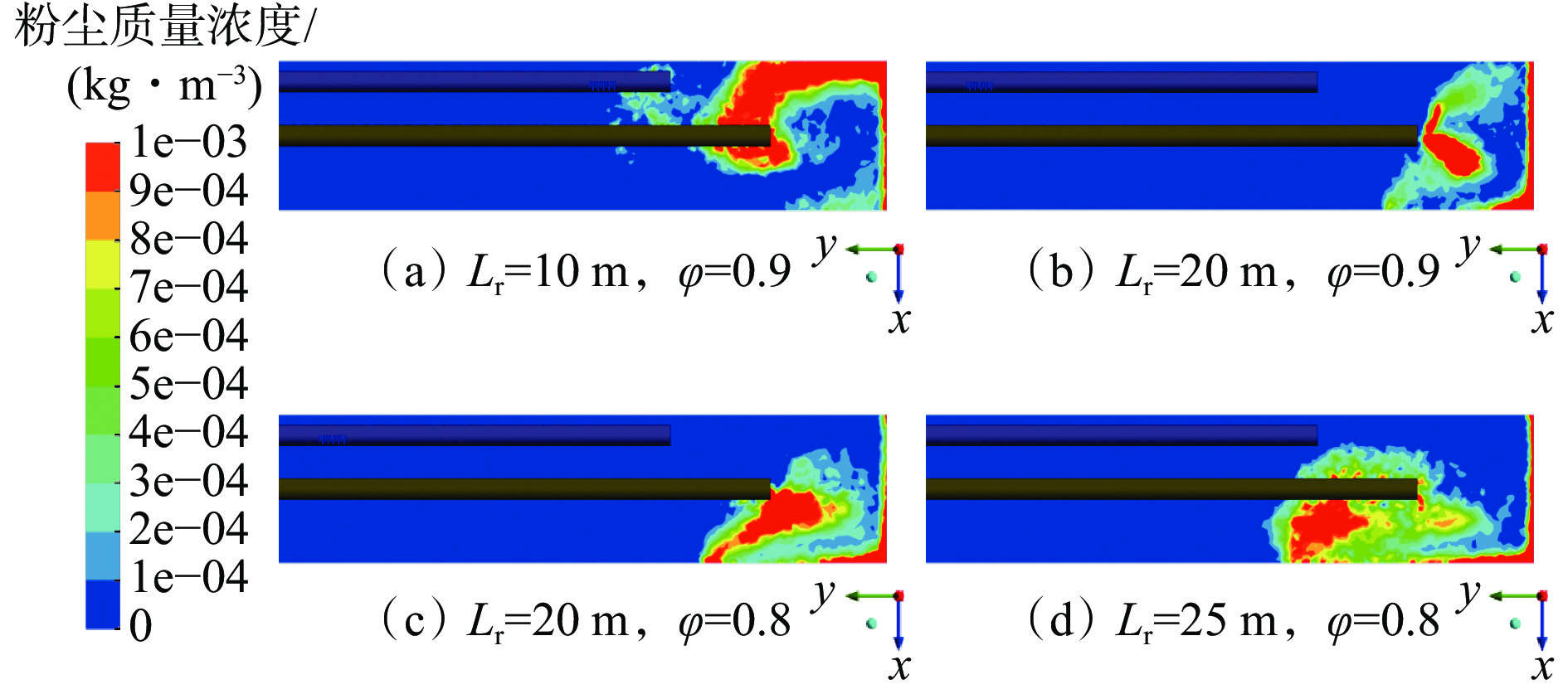

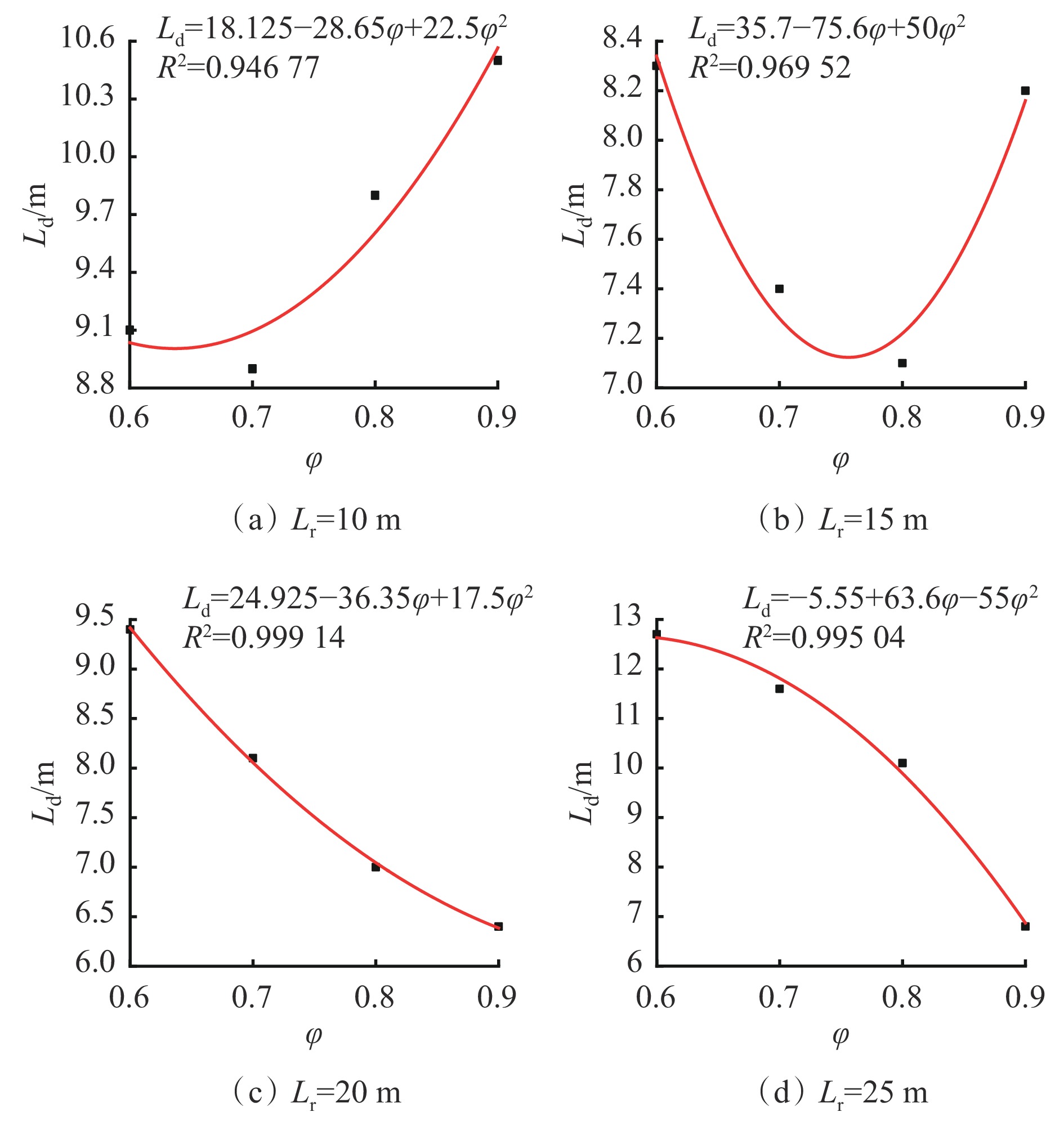

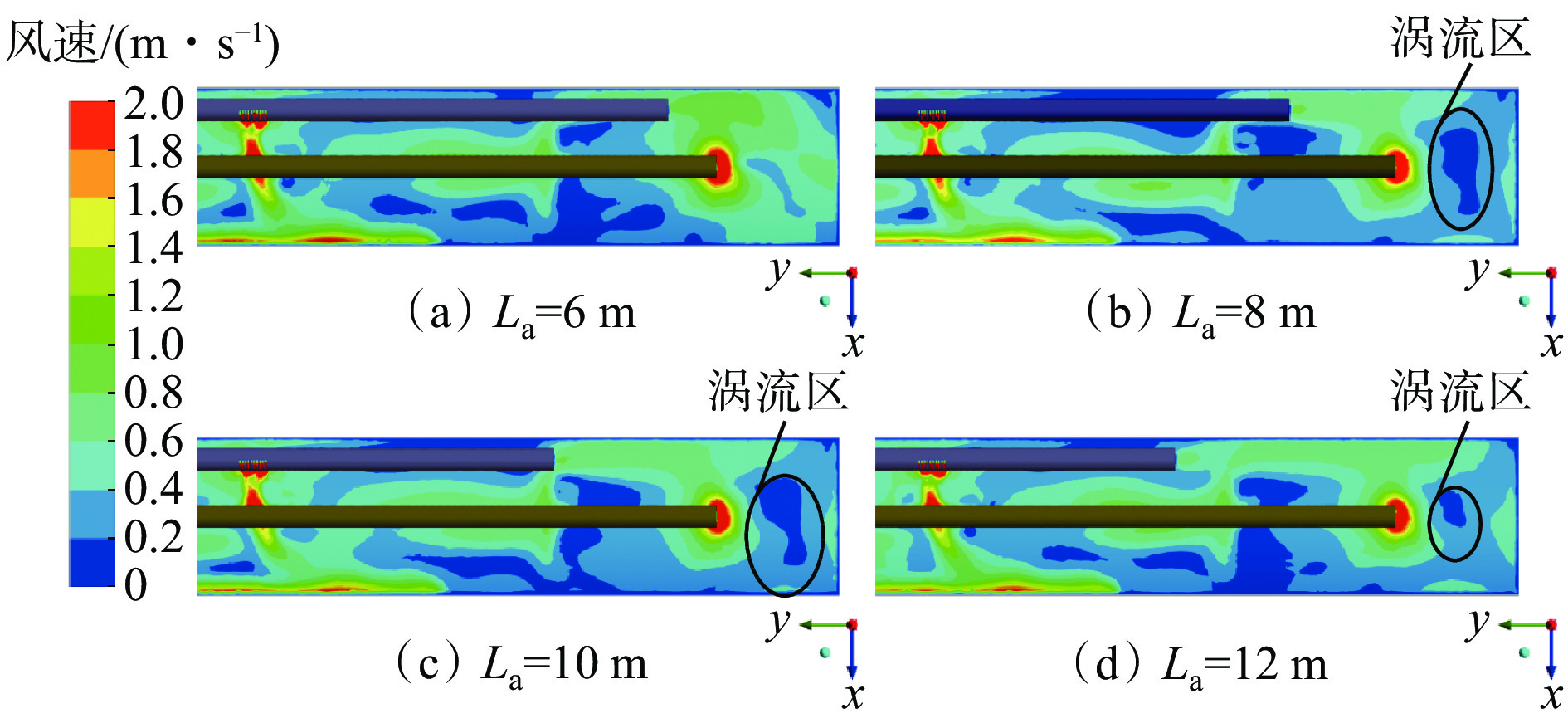

摘要: 目前综掘工作面粉尘污染的研究多集中于单一因素对综掘工作面风幕阻尘效果的影响,而未充分考虑各因素间的交互作用,使得压风分流技术的工程应用效果欠佳。为明确附壁风筒径向出风距离、径向出风比及轴向出风距离对风幕阻尘效果的影响,以潘三矿810西翼机巷综掘工作面为研究对象,运用Fluent软件对径向出风距离为10~25 m、径向出风比为0.6~0.9及轴向出风距离为6~12 m条件下的风流分布和粉尘扩散情况进行数值模拟。结果表明:① 随着径向出风距离增大,径向涡流风幕在巷道内的转变更充分,综掘机司机前端的风流分布越均匀,更有利于形成风速方向均指向工作面的轴向阻尘风幕。当径向出风距离为10 m时,距工作面7 m断面内涡流特性明显,风速方向紊乱;当径向出风距离为25 m时,距工作面7 m断面内,风流分布趋于均匀,风速方向均指向工作面,形成了能够覆盖全断面的轴向阻尘风幕。② 随着径向出风比增大,整流风筒轴向风流风量减小,轴向风流风速和射流强度降低,轴向风流对综掘工作面前端气流的扰动减弱;径向出风比越大,越有利于形成风流方向指向工作面且能覆盖全断面的轴向阻尘流场,即轴向阻尘风幕。③ 径向涡流风幕的阻尘能力随径向出风比的增大先增强后减弱,轴向阻尘风幕的阻尘能力随径向出风比的增大而不断增强。④ 在采取压风分流风幕阻尘技术后,当压风总量为300 m3/min,吸风量为400 m3/min,附壁风筒径向出风距离为20 m,径向出风比为0.9,整流风筒轴向出风距离为8~10 m时,能很好地将粉尘聚集在吸尘口附近,达到高效控尘除尘的目的。在810西翼机巷综掘工作面进行现场测试,测点风速和粉尘质量浓度实测值与模拟值基本一致,高浓度粉尘被有效阻控于工作面前端,隔尘效果较为明显,验证了数值模拟的有效性。Abstract: Prevalent research on dust pollution during fully mechanized excavation has mainly focused on the impact of individual factors on the effectiveness of air curtains in fully mechanized excavation sites. However, scant research has been devoted to the interaction between factors, because of which pressure-induced air diversion technology has not been adequately applied to this context.To investigate the impact of the radial distance of the outlet of air, the ratio of this outlet, and the distance between the outlet and the wall-coated air duct on the effectiveness of dust blocking by air curtains, the authors of this study consider the excavation of the working face of the 810 west wing machine tunnel at the Pansan Mine . We used Fluent software to numerically simulate the distribution of wind flow and the diffusion of dust under a distance of the radial outlet of air of 10-25 m, a ratio of the outlet of 0.6-0.9, and an axial distance of the outlet of 6-12 m.The results showed that: ① As the distance of the radial outlet of air increased, the radial vortex air curtain transforms more fully in the tunnel . The wind flow at the front end of the excavation operator was more evenly distributed, and the wind speed was directed toward the working face such that this was more conducive to the formation of an axial dust-blocking air curtain.When the radial distance of the outlet of air was 10 m, vortical characteristics became apparent within a distance of 7 m from the working surface, and the direction of wind became disordered. When the radial distance of the air outlet was 25 m, the wind flow tended to be uniform within 7 m of the working surface, and its direction was evenly distributed toward the working surface. This led to the formation of an axial dust-blocking wind curtain that could cover the entire section.② As the ratio of the radial outlet of air increased, the volume of axial airflow of the rectifier air cylinder decreased to reduce the velocity of axial airflow and the intensity of the jet. This in turn reduced the disturbance caused by the axial airflow to that at the top of the mechanized working face that was being excavated. A higher ratio of the radial outlet of air was more conducive to the formation of an axial dust-blocking flow field, with the wind directed toward the working surface and covering the entire section. This led to an axial dust-blocking air curtain. ③ The dust-blocking ability of the radial vortical air curtain initially increased and then decreased as the ratio of the radial outlet of air increased. Its ability then continued to improve as the ratio was further increased. ④ We implemented the dust-control technology based on the air curtain with forced ventilation-induced diversion. When the pressure-induced volume of air was 300 m3/min and the volume of air suction was 400 m3/min, the distance between the radial outlet of air and the attached wall of the air duct was 20 m. The ratio of the radial outlet of air, and the distance between this outlet and the air duct of the rectifier was 8-10 m. The air curtain was able to collect dust near the port of the dust suction for efficient dust control and removal.We conducted an on-site test of the fully mechanized excavation working face of the 810 west wing machine tunnel. The empirically measured data of wind speed and dust mass concentration at measuring points and the results of numerical simulations were consistent with each other. Highly concentrated dust was blocked at the front end of the working face, and its isolation was noticeable. This confirms the effectiveness of the numerical simulations.

-

-

表 1 不同Lr及φ条件下粉尘扩散距离Ld

Table 1 Dust diffusion distance Ld under different Lr and φ condition

Lr/m Ld/m φ=0.6 φ=0.7 φ=0.8 φ=0.9 10 9.1 8.9 9.8 10.5 15 8.3 7.4 7.1 8.2 20 9.4 8.1 7.0 6.4 25 12.7 11.6 10.1 6.8 表 2 各断面测点风速

Table 2 Wind speed at measuring points of each section

距工作面距离/m A点风速/(m·s−1) B点风速/(m·s−1) 实测值 模拟值 实测值 模拟值 5 0.48 0.54 0.39 0.45 10 0.43 0.51 0.36 0.43 20 1.16 1.32 0.87 0.97 表 3 各断面测点粉尘质量浓度

Table 3 Dust concentration measuring value of each section

距工作面距离/m 粉尘质量浓度/(mg·m−3) 3 208.8 5 63.3 7 33.6 -

[1] 龚晓燕,赵晓莹,杨富强,等. 综掘面尘源动态变化下粉尘场优化的风流调控研究[J]. 煤炭工程,2021,53(2):122-126. GONG Xiaoyan,ZHAO Xiaoying,YANG Fuqiang,et al. Wind flow control for optimization of dust field distribution under dynamic change of dust source in fully mechanized heading face[J]. Coal Engineering,2021,53(2):122-126.

[2] 秦翥. 带式输送机转载点粉尘浓度分布数值模拟[J]. 工矿自动化,2018,44(7):70-74. QIN Zhu. Numerical simulation of dust concentration distribution in transfer site of belt conveyor[J]. Industry and Mine Automation,2018,44(7):70-74.

[3] 龚晓燕,张浩,陈龙,等. 综掘面抽风口调控下的旋流风幕降尘优化[J]. 中国安全科学学报,2023,33(6):56-63. GONG Xiaoyan,ZHANG Hao,CHEN Long,et al. Optimization of cyclone air curtain dust control under control of exhaust outlet on fully mechanized excavation face[J]. China Safety Science Journal,2023,33(6):56-63.

[4] 程卫民,周刚,陈连军,等. 我国煤矿粉尘防治理论与技术20年研究进展及展望[J]. 煤炭科学技术,2020,48(2):1-20. CHENG Weimin,ZHOU Gang,CHEN Lianjun,et al. Research progress and prospect of dust control theory and technology in China's coal mines in the past 20 years[J]. Coal Science and Technology,2020,48(2):1-20.

[5] 吕英华,察兴鹏,聂文,等. 基于数值模拟的喷雾装置粉尘抑制研究[J]. 煤矿机械,2022,43(11):34-37. LYU Yinghua,CHA Xingpeng,NIE Wen,et al. Study on dust suppression of spray device based on numerical simulation[J]. Coal Mine Machinery,2022,43(11):34-37.

[6] 张义坤. 煤矿综掘面泡沫降尘技术研究与实施[J]. 中国安全科学学报,2012,22(2):151-156. ZHANG Yikun. Study on dust control technology with foam in fully mechanized workface of Huoerxinhe Coal Mine[J]. China Safety Science Journal,2012,22(2):151-156.

[7] 蒋仲安,杨斌,张国梁,等. 高原矿井掘进工作面截割粉尘污染效应及通风控尘参数分析[J]. 煤炭学报,2021,46(7):2146-2157. JIANG Zhong'an,YANG Bin,ZHANG Guoliang,et al. Analysis of dust pollution effect of cutting dust and ventilation control parameters at the heading face in plateau mines[J]. Journal of China Coal Society,2021,46(7):2146-2157.

[8] 秦跃平,张苗苗,崔丽洁,等. 综掘工作面粉尘运移的数值模拟及压风分流降尘方式研究[J]. 北京科技大学学报,2011,33(7):790-794. QIN Yueping,ZHANG Miaomiao,CUI Lijie,et al. Numerical simulation of dust migration and study on dust removal modes with the forced ventilation shunt in a fully mechanized workface[J]. Journal of University of Science and Technology Beijing,2011,33(7):790-794.

[9] 聂文,程卫民,周刚. 综掘工作面压风气幕形成机理与阻尘效果分析[J]. 煤炭学报,2015,40(3):609-615. NIE Wen,CHENG Weimin,ZHOU Gang. Formation mechanism of pressure air curtain and analysis of dust suppression's effects in mechanized excavation face[J]. Journal of China Coal Society,2015,40(3):609-615.

[10] LIU Qiang,NIE Wen,HUA Yun,et al. The effects of the installation position of a multi-radial swirling air-curtain generator on dust diffusion and pollution rules in a fully-mechanized excavation face:a case study[J]. Powder Technology,2018,329:371-385. DOI: 10.1016/j.powtec.2018.01.064

[11] 陈芳,张设计,马威,等. 综掘工作面压风分流控除尘技术研究与应用[J]. 煤炭学报,2018,43(增刊2):483-489. CHEN Fang,ZHANG Sheji,MA Wei,et al. Research and application of the technology of forced ventilation diversion to control and reduce dust in fully mechanized excavation face[J]. Journal of China Coal Society,2018,43(S2):483-489.

[12] 王建国,王康,樊亦洋. 附壁风筒条缝参数对综掘工作面控尘效果的影响[J]. 煤矿安全,2021,52(6):206-210. WANG Jianguo,WANG Kang,FAN Yiyang. Influence of slot parameters of wall-attached air duct on dust control effect of fully mechanized mining face[J]. Safety in Coal Mines,2021,52(6):206-210.

[13] 王昊,张永亮,撒占友,等. 综掘工作面压抽风量比对多径向涡旋气幕阻尘效果的影响[J]. 矿业安全与环保,2022,49(2):117-121,126. WANG Hao,ZHANG Yongliang,SA Zhanyou,et al. Effect of the forced-suction airflow volume ratio on the dust suppression of swirling air curtain in fully mechanized excavation face[J]. Mining Safety & Environmental Protection,2022,49(2):117-121,126.

[14] 龚晓燕,彭高高,宋涛,等. 掘进工作面长压短抽通风出风口风流调控参数研究[J]. 工矿自动化,2021,47(9):45-52. GONG Xiaoyan,PENG Gaogao,SONG Tao,et al. Study on air flow control parameters of long-pressure and short-extraction ventilation air outlets in heading face[J]. Industry and Mine Automation,2021,47(9):45-52.

[15] 陈芳. 综掘工作面分段控风控尘技术研究与应用[J]. 煤炭工程,2019,51(12):106-110. CHEN Fang. Research and application of sectional airflow and dust control technology in fully mechanized tunnelling face[J]. Coal Engineering,2019,51(12):106-110.

[16] 程卫民,王昊,孙彪,等. 综掘面径向分风与压风配比对风幕阻尘的影响[J]. 中国矿业大学学报,2017,46(5):1014-1023. CHENG Weimin,WANG Hao,SUN Biao,et al. Effects of ratio of radial partial air volume to pressure air volume on air curtain dust control at fully mechanized working face[J]. Journal of China University of Mining & Technology,2017,46(5):1014-1023.

[17] 韩敏,王建国,王康. 多抽风筒对综掘面除尘的影响研究[J]. 矿业安全与环保,2022,49(5):114-118. HAN Min,WANG Jianguo,WANG Kang. Study on the influence of multiple exhaust pipes on dust removal in fully mechanized excavation face[J]. Mining Safety & Environmental Protection,2022,49(5):114-118.

[18] 王昊,撒占友,王春源,等. 综掘工作面通风条件对径向旋流风幕阻尘效果的影响[J]. 煤矿安全,2022,53(3):186-192. WANG Hao,SA Zhanyou,WANG Chunyuan,et al. Influences of ventilation conditions of fully mechanized excavation face on dust-resistance effect of radial swirling air curtain[J]. Safety in Coal Mines,2022,53(3):186-192.

[19] 杨泽安,王义亮. 综掘工作面湿式除尘条件下尘雾耦合数值模拟[J]. 煤矿安全,2021,52(11):170-175. YANG Ze'an,WANG Yiliang. Numerical simulation of dust and spray coupling under wet dust removal condition in fully mechanized excavation face[J]. Safety in Coal Mines,2021,52(11):170-175.

[20] 魏星,高丹红,张国宝. 旋流气幕系统对综掘面控尘流场的影响研究[J]. 矿业研究与开发,2019,39(12):109-115. WEI Xing,GAO Danhong,ZHANG Guobao. The impact of swirling air curtain system on the dust control flow field in the fully-mechanized excavation face[J]. Mining Research and Development,2019,39(12):109-115.

[21] 王磊,程煜,徐荣萧. 基于EDEM仿真的煤岩截割产尘规律研究[J]. 煤矿安全,2023,54(1):22-28. WANG Lei,CHENG Yu,XU Rongxiao. Mechanism of dust production during coal and rock cutting based on EDEM[J]. Safety in Coal Mines,2023,54(1):22-28.

[22] 邹常富. 岩巷产尘规律及控风除尘技术研究[J]. 煤炭技术,2021,40(4):77-79. ZOU Changfu. Research on dust generation law of rock drift and wind control and dust removal technology[J]. Coal Technology,2021,40(4):77-79.

[23] 侯树宏,郝军,李腾龙,等. 综掘工作面通风控尘参数匹配关系研究及应用[J]. 煤炭技术,2022,41(1):166-169. HOU Shuhong,HAO Jun,LI Tenglong,et al. Research and application of ventilation and dust control parameters matching in fully mechanized driving face[J]. Coal Technology,2022,41(1):166-169.

[24] 张义坤,蒋仲安,孙雅茹. 附壁风筒对掘进工作面通风除尘的促进作用[J]. 煤矿安全,2017,48(12):161-163. ZHANG Yikun,JIANG Zhong'an,SUN Yaru. Promotion effect of dust removal in heading face by ventilation duct with coanda effect[J]. Safety in Coal Mines,2017,48(12):161-163.

-

期刊类型引用(2)

1. 陈华颖,杜志刚,宋兴家. 矿用综合调度管控平台设计. 工矿自动化. 2022(08): 122-126 .  本站查看

本站查看

2. 王宾,崔楠楠. 新桥煤矿井4G通信系统建设. 现代矿业. 2019(05): 32-35 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: