Numerical simulation study on the coal-bed methane displacement effect of different gas injection components

-

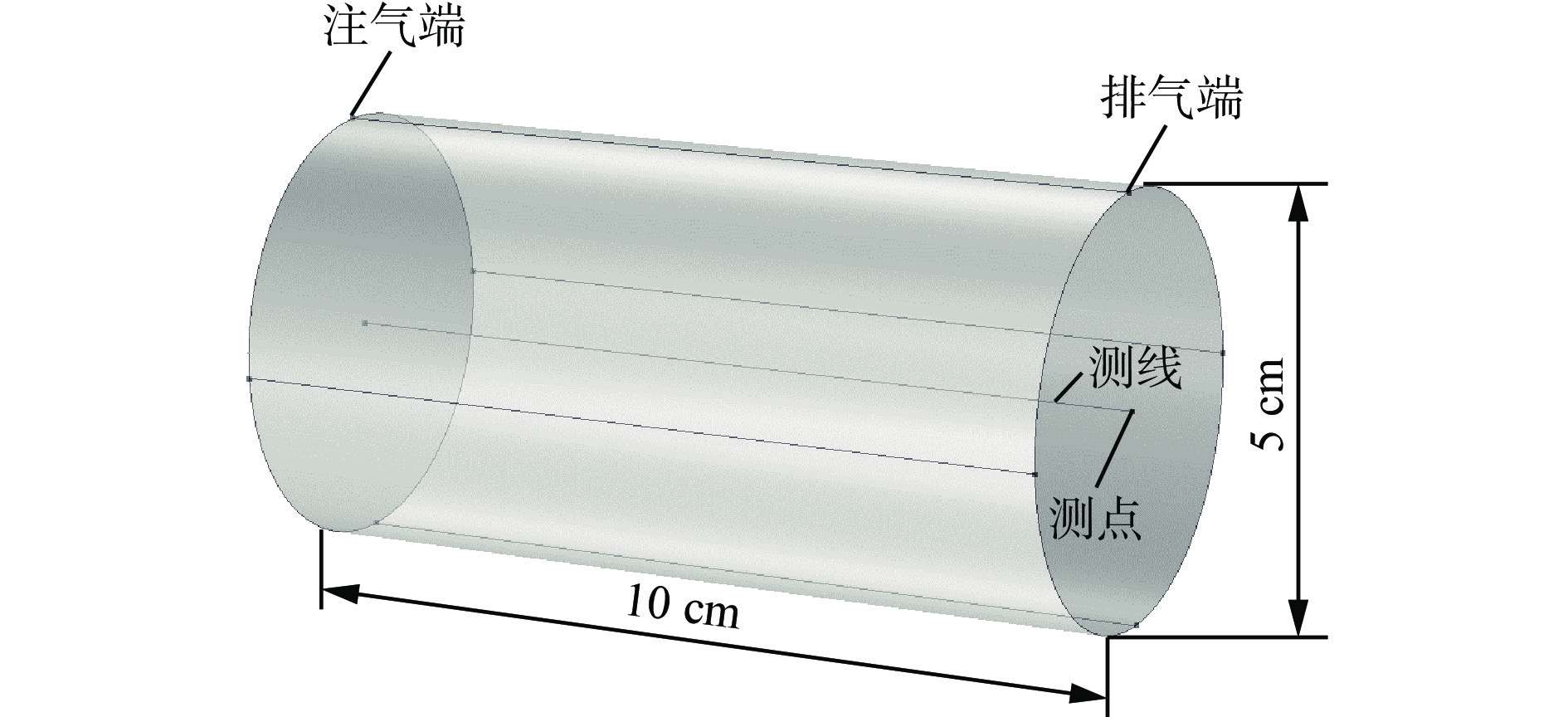

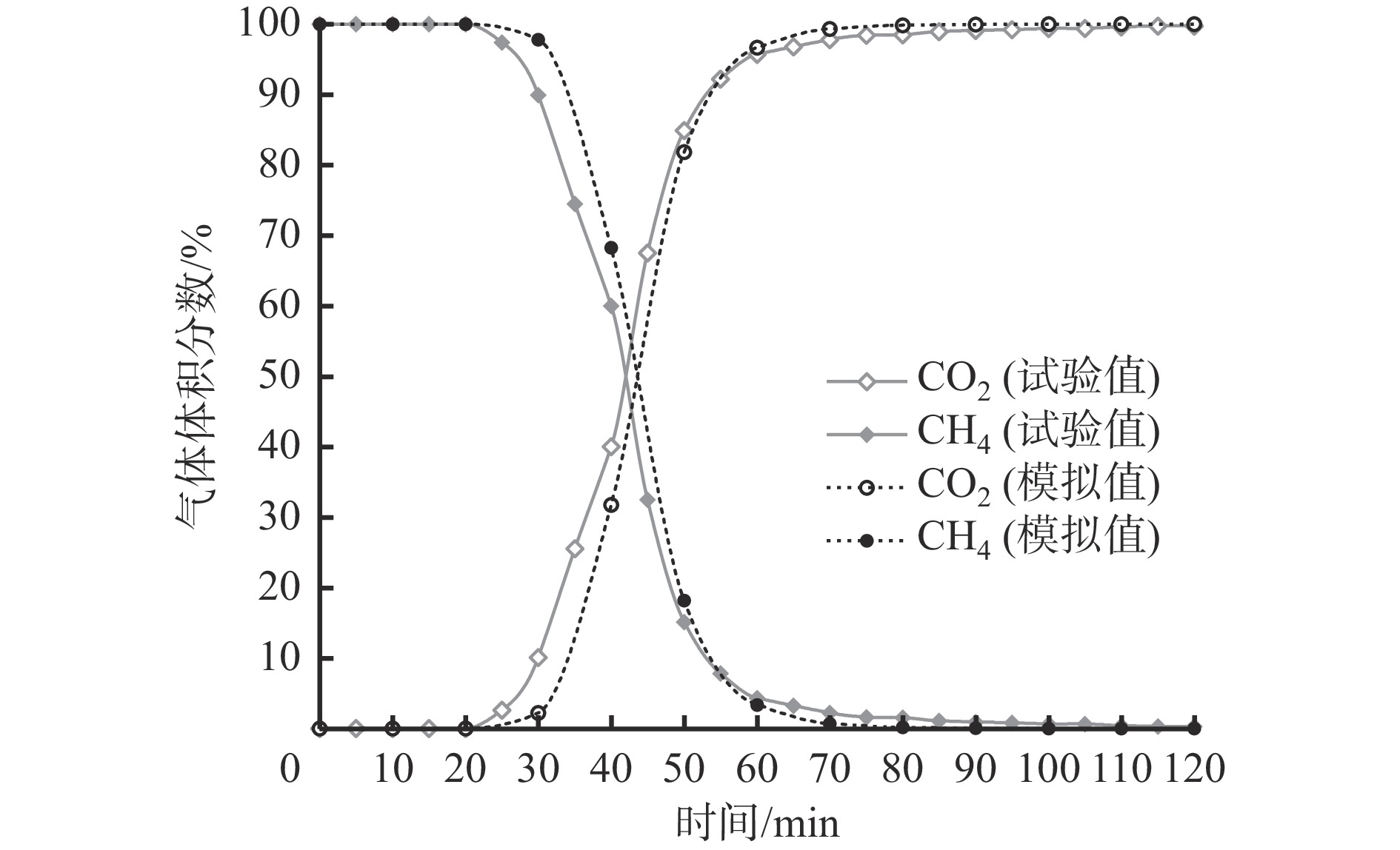

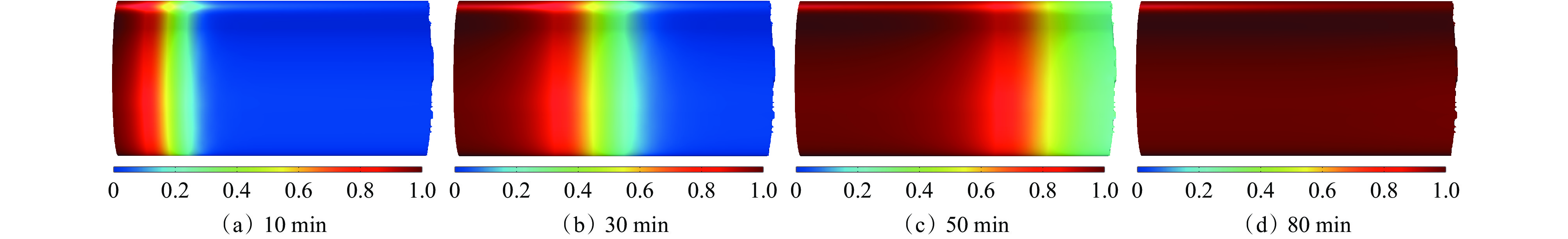

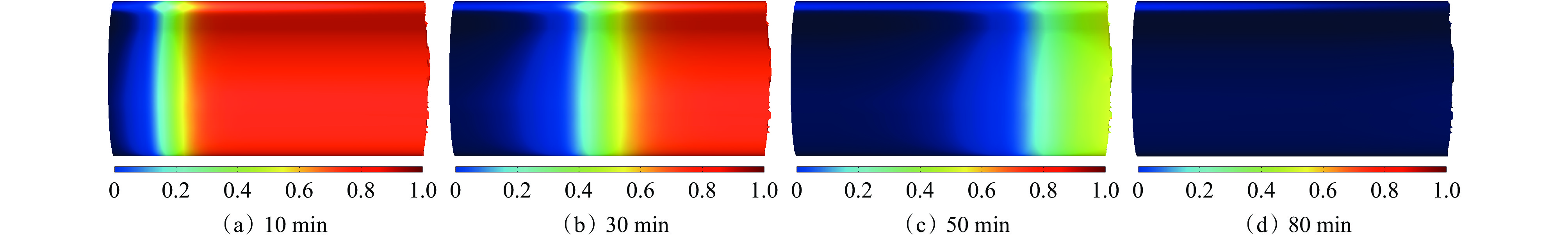

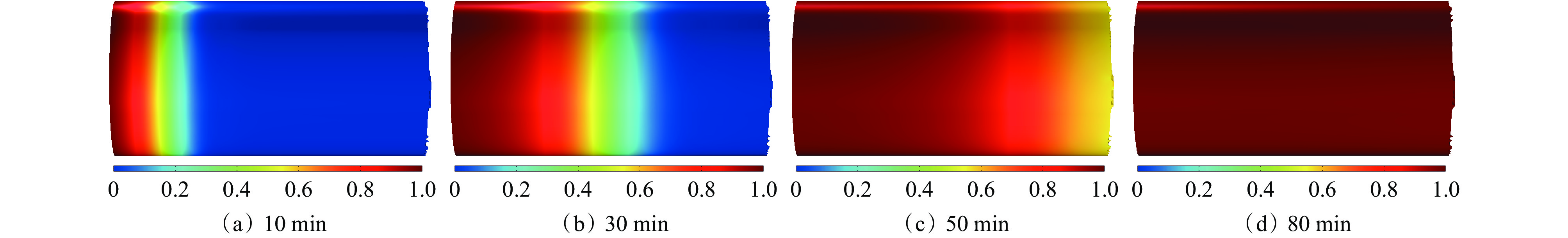

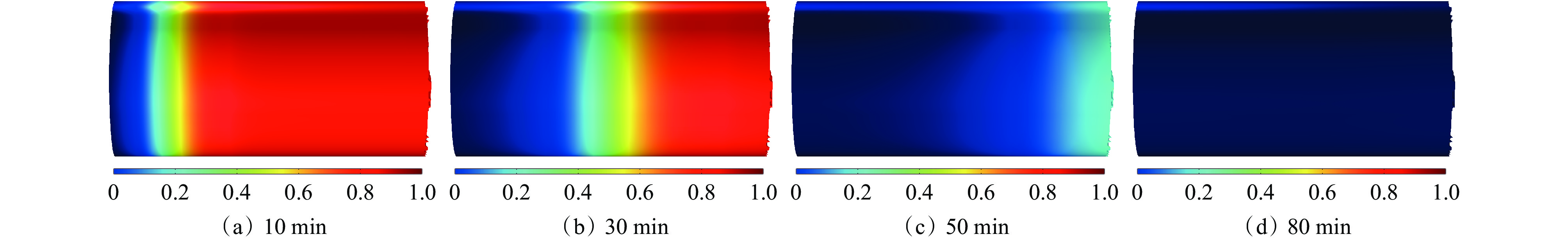

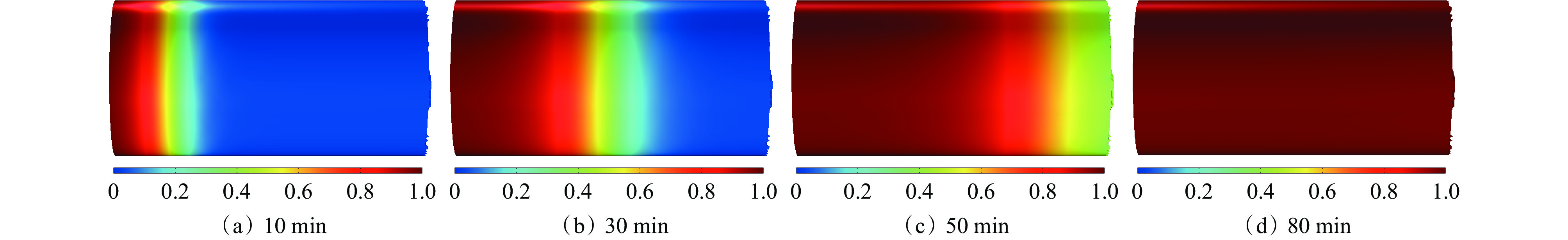

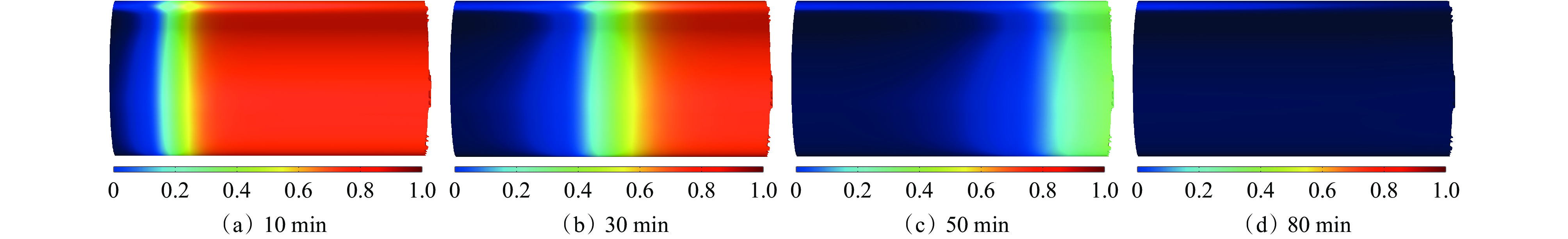

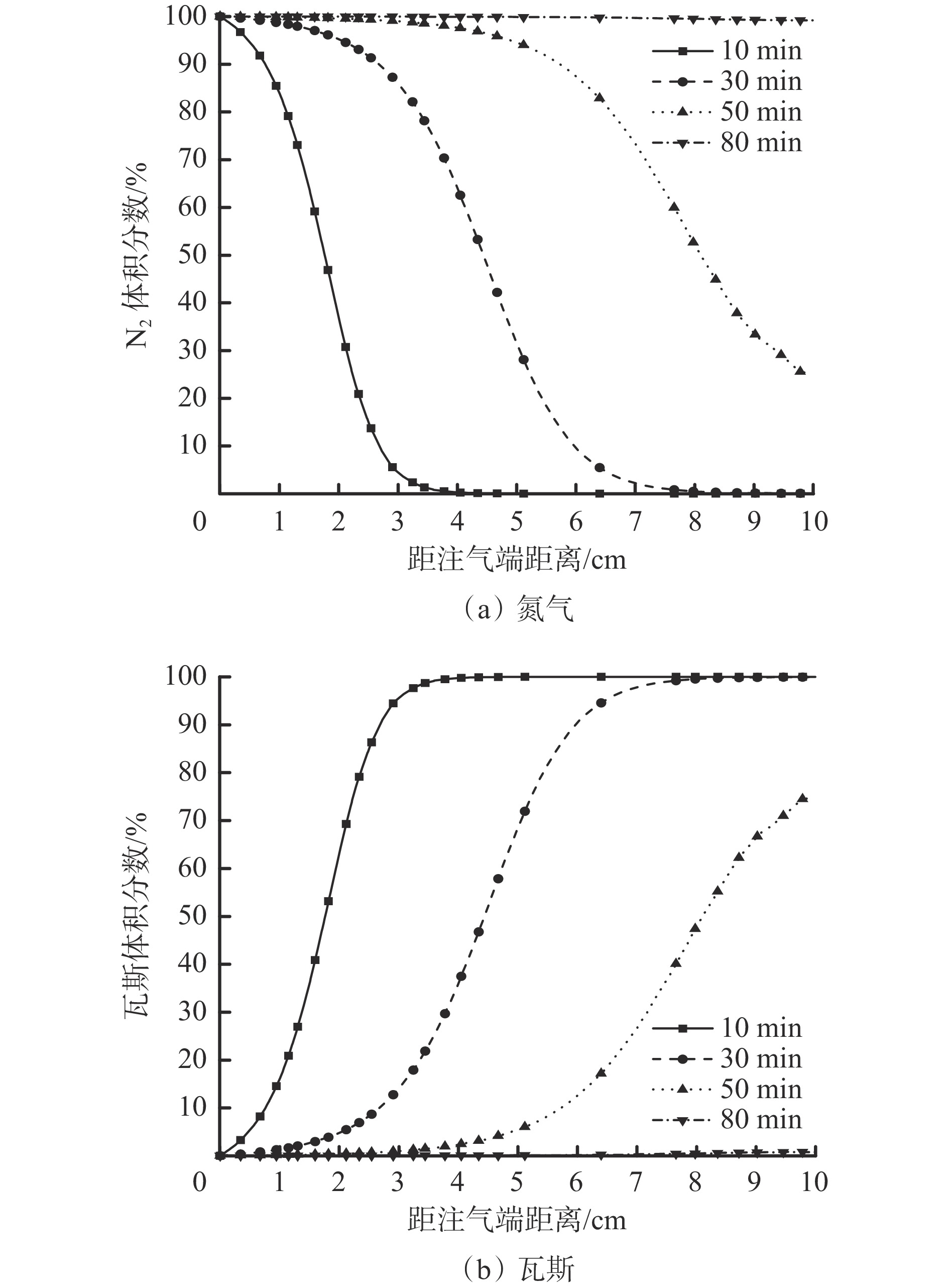

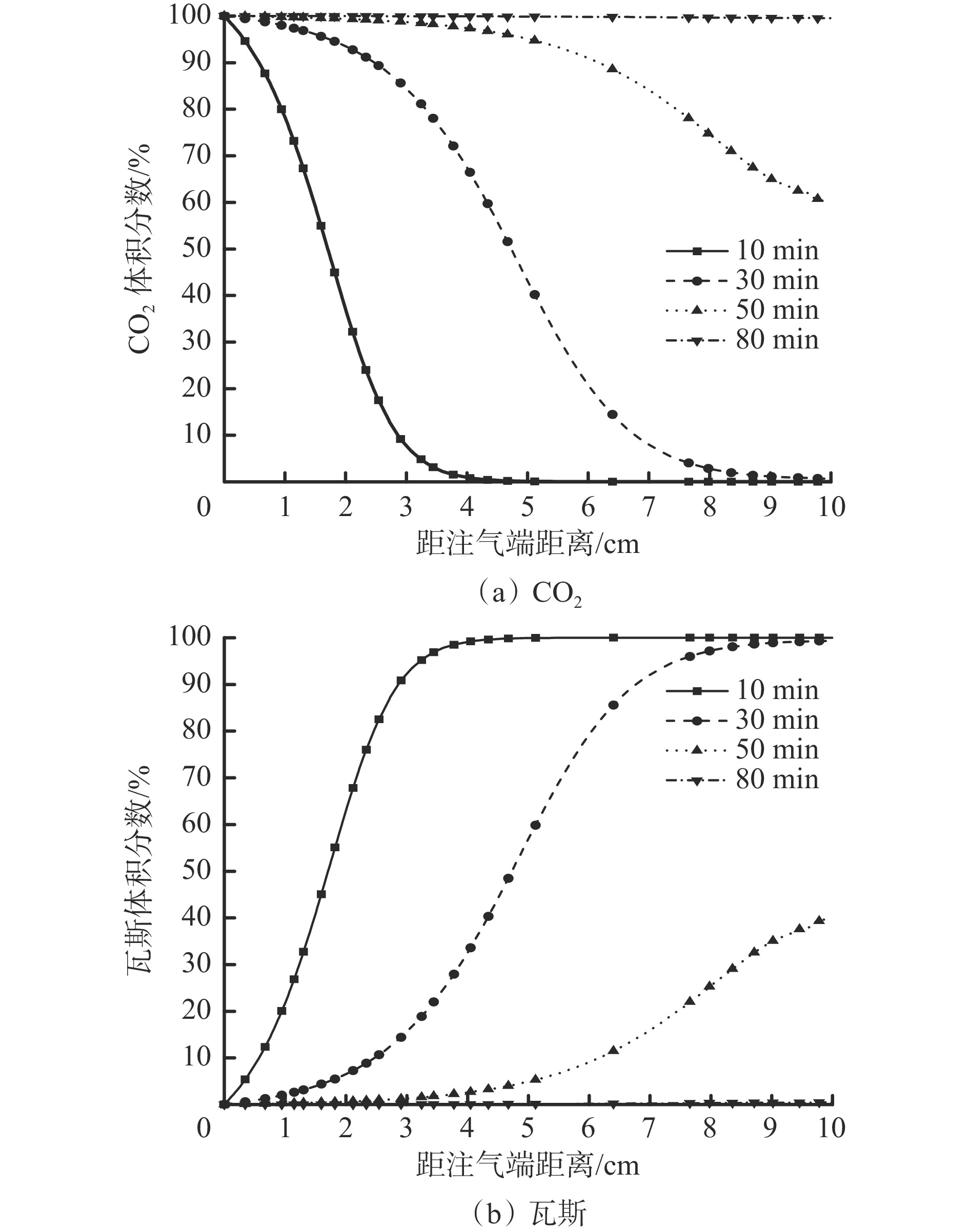

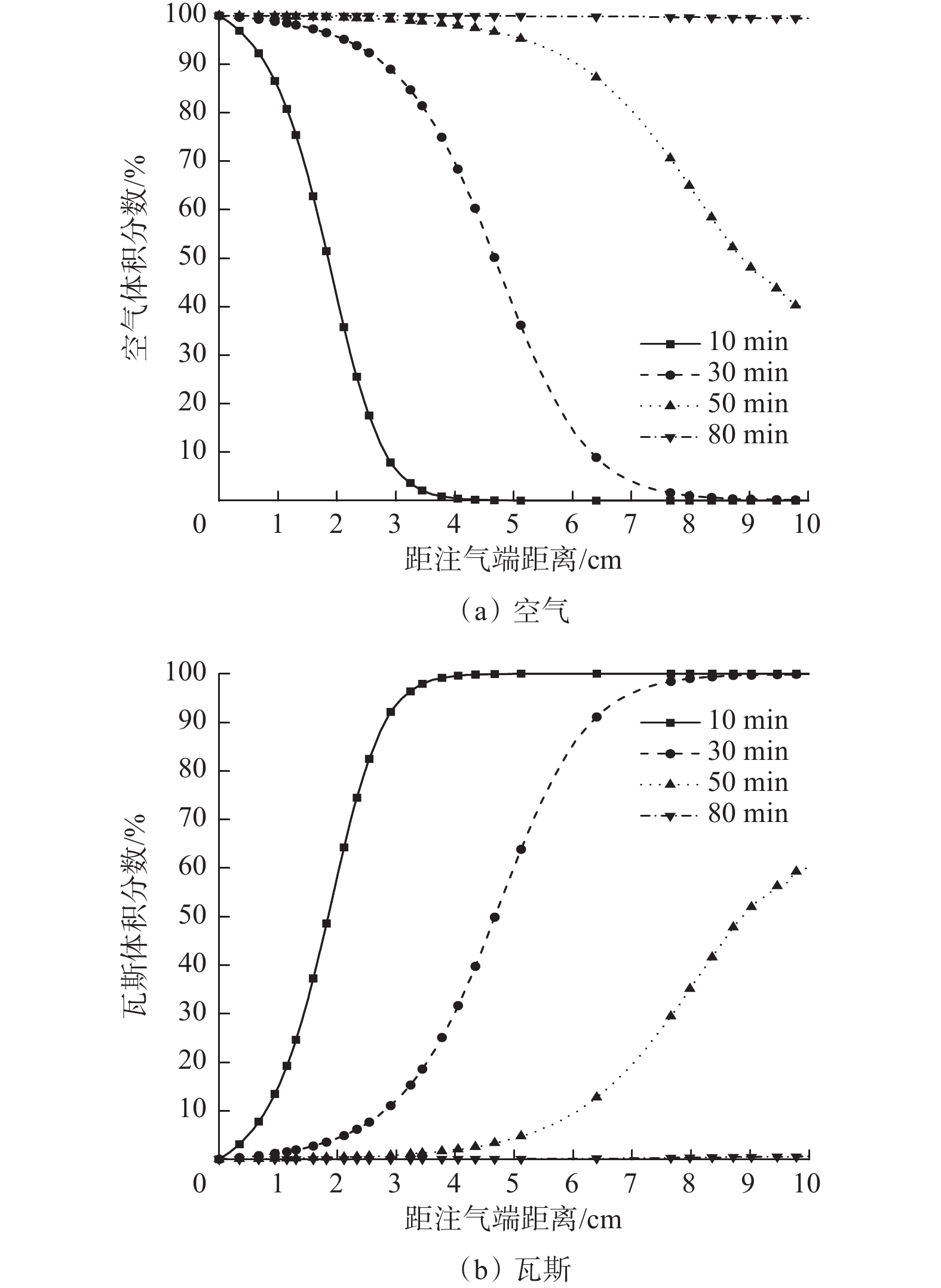

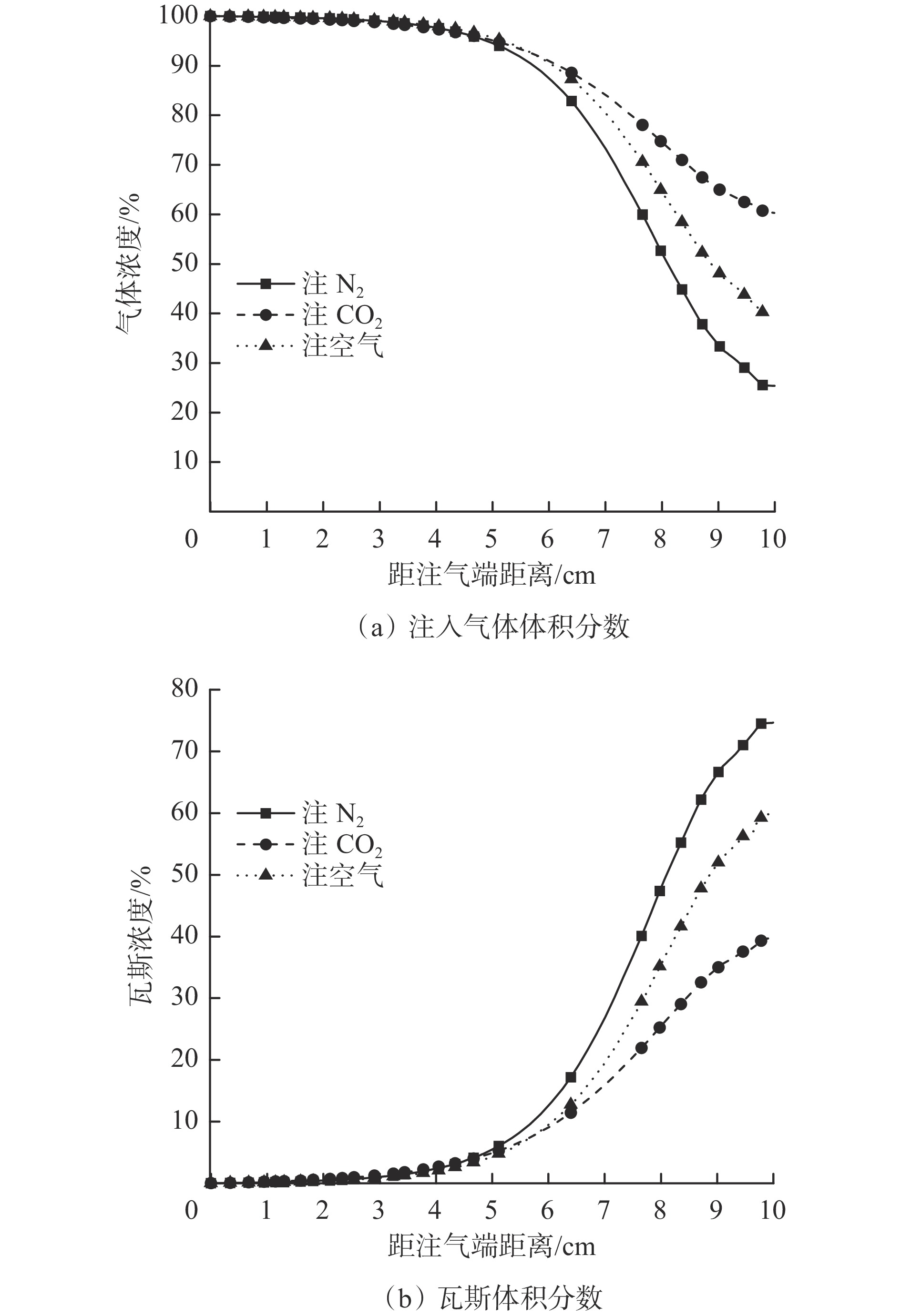

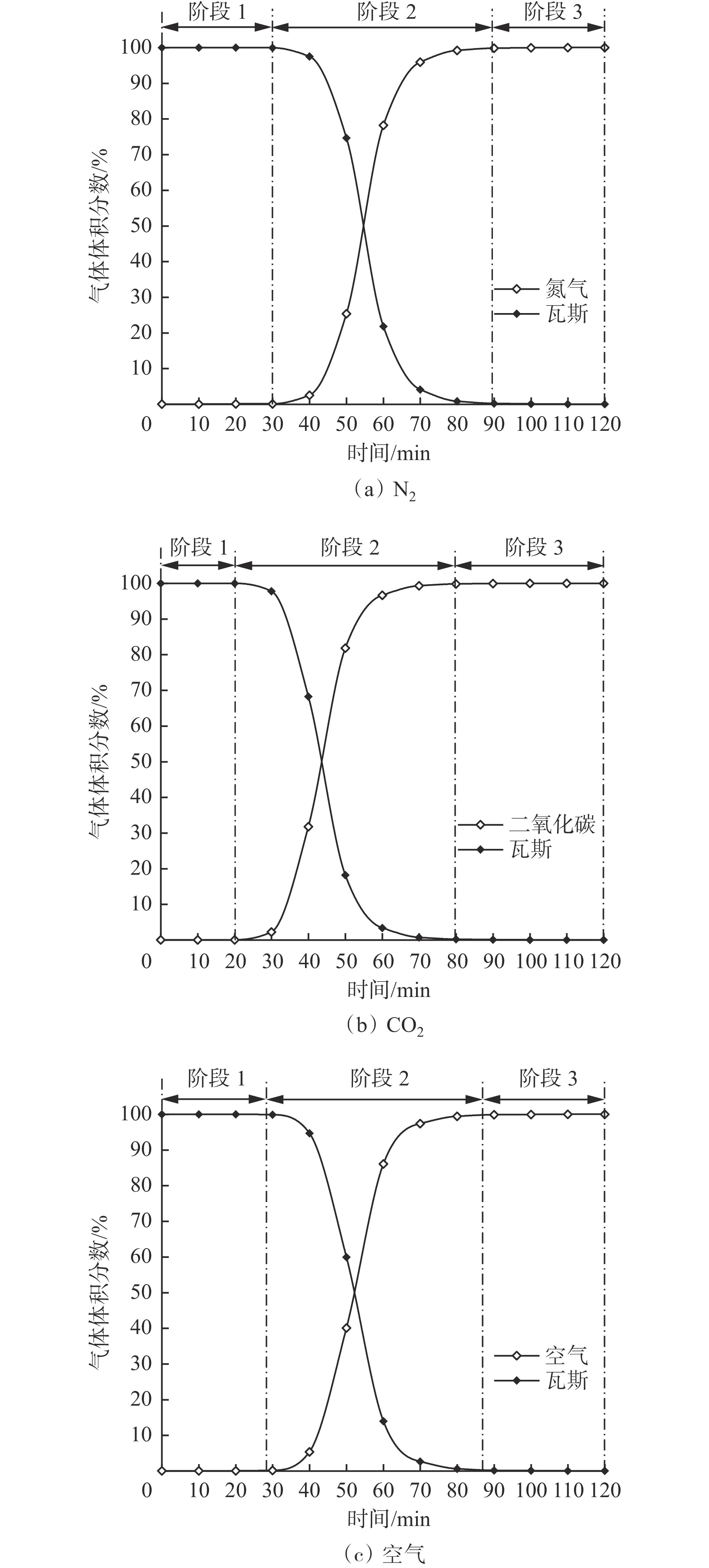

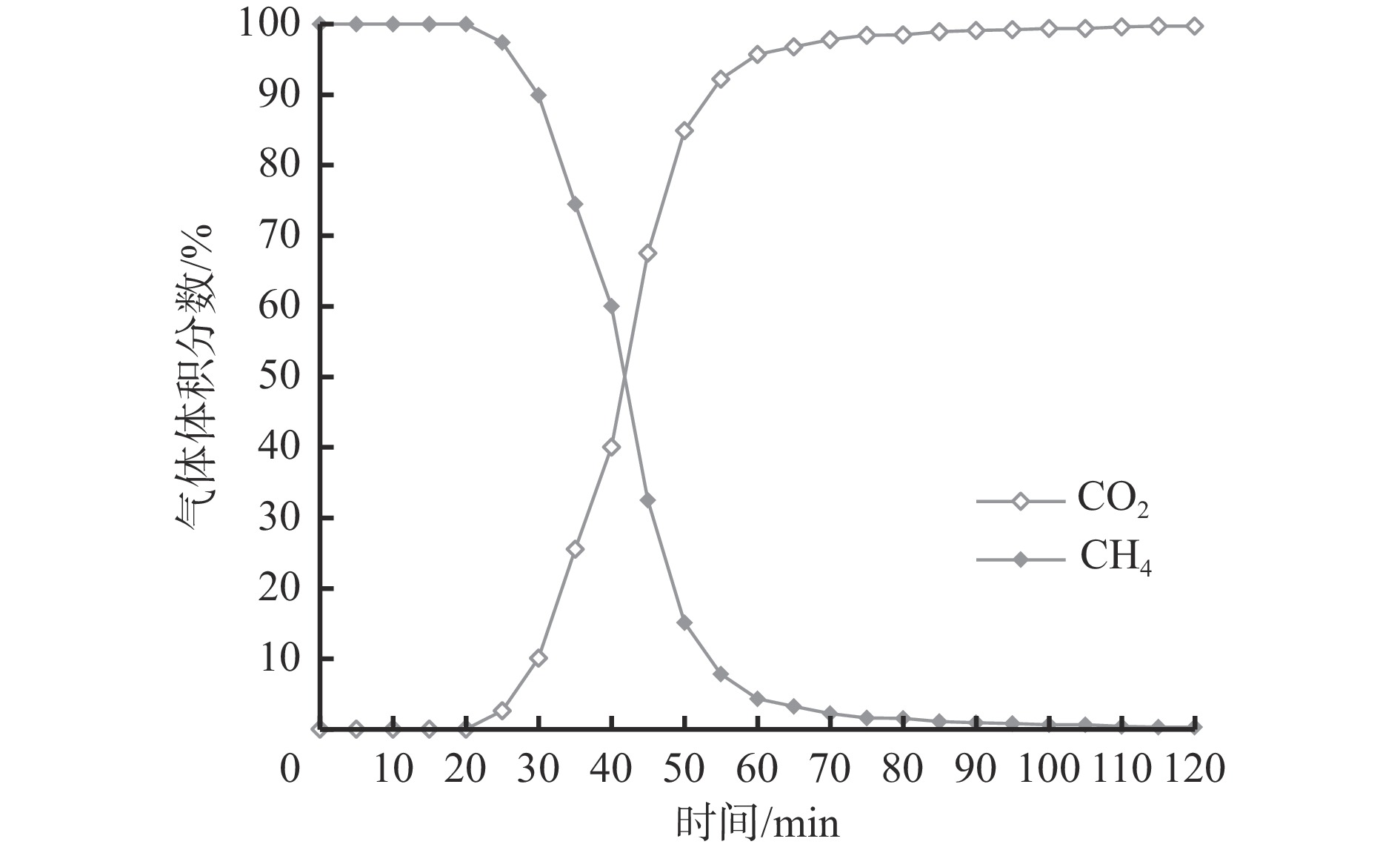

摘要: 注气促抽瓦斯的注气成分主要有N2,CO2和空气,但目前针对不同注入成分的置驱效果对比研究较少。针对该问题,建立了考虑裂隙气体渗流和基质孔隙气体扩散的注气成分置驱瓦斯数学模型,在对该模型验证的基础上,模拟注入气体置驱煤样瓦斯气体过程,并对比研究相同注气压力和煤体渗透率条件下不同注气成分(N2,CO2和空气)对瓦斯的置驱效果。结果表明:① 相同注气时间下,从注气端到排气端,注入气体的体积分数逐渐降低,在注气端附近注入气体的体积分数最高;瓦斯体积分数逐渐增加,在排气端附近瓦斯体积分数最高;随着注气时间增加,注入气体的体积分数增加区域逐渐向排气端移动直至覆盖整个煤样,瓦斯体积分数降低区域也逐渐向排气端移动直至覆盖整个煤样,表明煤样中的瓦斯逐渐被置换出来,进而被驱替出整个煤样。② 在相同注气时间内,从注气端到排气端,N2,CO2和空气3种注入气体体积分数和瓦斯体积分数具有相似的变化规律,即从注气端到排气端,注入气体体积分数逐渐降低、瓦斯体积分数逐渐升高,随着注气时间增加,注入气体的体积分数增高区域增加。相同注气时间、煤样相同位置处注入气体的体积分数和瓦斯体积分数互补,即相加为100%。③ 3种注入气体对瓦斯的置驱效果排序为CO2>空气>N2。④ 对排气端气体的体积分数分析可知,排气端气体的体积分数随时间变化可分为突破阶段、平衡进行阶段和置驱完成阶段。不同注入气体3个阶段持续时间不同,注入N2突破时间和置驱完成时间分别为30,90 min;注入CO2突破时间和置驱完成时间分别为20,80 min;注入空气突破时间和置驱完成时间分别为28,87 min。⑤ 在现场应用时,应根据具体煤层的吸附解吸能力、煤层自燃特性等选择合适的注入气体。Abstract: The main components of gas injection to promote methane extraction are N2, CO2, and air, but there is currently limited research on the comparison of displacement effects for different injection components. In order to solve the above problems, a mathematical model for gas injection displacement considering fracture gas seepage and matrix pore gas diffusion is established. Based on the validation of the model, the process of injecting gas into coal samples for methane displacement is simulated. The effects of different injection components (N2, CO2, and air) on methane displacement are compared and studied under the same injection pressure and coal permeability conditions. The results show the following points. ① Under the same injection time, the volume fraction of injected gas gradually decreases from the injection end to the exhaust end, with the highest injected gas volume fraction near the injection end. The methane volume fraction gradually increases, with the highest methane volume fraction near the exhaust end. As the injection time increases, the area with an increase in injected gas volume fraction gradually moves towards the exhaust end until it covers the entire coal sample. The area with a decrease in methane volume fraction also gradually moves towards the exhaust end until it covers the entire coal sample. It indicates that the methane in the coal sample is gradually displaced and driven out of the whole sample. ② Within the same injection time, from the injection end to the exhaust end, the volume fractions of N2, CO2, and air injected gases and methane have similar changes. That is, from the injection end to the exhaust end, the volume fraction of injected gas gradually decreases and the methane volume fraction gradually increases. With the increase of injection time, the area of increase in injected gas volume fraction increases. The volume fraction of injected gas and methane at the same injection time and at the same position of the coal sample complement each other, that is, they add up to 100%. ③ The ranking of the methane displacement effects of three types of injected gases is CO2>air> N2. ④ The analysis of the gas volume fraction at the exhaust end shows that the gas volume fraction at the exhaust end can be divided into breakthrough stage, equilibrium stage, and displacement completion stage over time. The duration of the three stages of injecting different gases varies, with N2 breakthrough time and displacement completion time of 30 and 90 minutes, respectively. The breakthrough time for CO2 injection and the completion time for displacement are 20 and 80 minutes, respectively. The breakthrough time for air injection and the completion time for displacement are 28 and 87 minutes, respectively. ⑤ When applied on site, appropriate injection gases should be selected based on the adsorption and desorption capacity of specific coal seams, as well as the spontaneous combustion features of coal seams.

-

-

表 1 模拟参数

Table 1 Simulation parameters

参数 值 煤体孔隙率 0.075 煤体密度/(kg$\cdot $m−3) 1 400 CH4标况密度/(kg$\cdot $m−3) 0.668 CH4动力黏度/(Pa$\cdot $s) 1.03×10−5 CH4摩尔质量/(kg$\cdot $mol−1) 0.016 CO2标况密度/(kg$\cdot $m−3) 1.977 CO2动力黏度/(Pa$\cdot $s) 1.38×10−5 CO2摩尔质量/(kg$\cdot $mol−1) 0.044 气体常数/(J$\cdot $mol−1$\cdot $K−1) 8.314 煤体温度/K 293 表 2 N2和空气参数

Table 2 Parameters of N2 and air

参数 值 N2标况密度/(kg$\cdot $m−3) 1.165 N2动力黏度/(Pa$\cdot $s) 1.76×10−5 N2摩尔质量/(kg$\cdot $mol−1) 0.028 空气标况密度/(kg$\cdot $m−3) 1.293 空气动力黏度/(Pa$\cdot $s) 1.5×10−5 空气摩尔质量/(kg$\cdot $mol−1) 0.029 -

[1] 范鹏鹏,刘晓,陈贞龙,等. 中美煤层气勘探开发现状对比及启示[J]. 现代化工,2023,43(8):22-25,30. FAN Pengpeng,LIU Xiao,CHEN Zhenlong,et al. Comparison and enlightenment of current situation of coalbed methane exploration and development between China and the United States[J]. Modern Chemical Industry,2023,43(8):22-25,30.

[2] 范超军,王一琦,杨雷,等. 2012—2021年我国煤矿安全事故统计与规律分析[J]. 矿业研究与开发,2023,43(4):182-188. FAN Chaojun,WANG Yiqi,YANG Lei,et al. Statistics and regularity analysis of coal mine safety accidents from 2012 to 2021[J]. Mining Research and Development,2023,43(4):182-188.

[3] 郭翔. “孤岛”变长工作面瓦斯涌出规律及治理技术研究[J]. 煤炭科学技术,2022,50(增刊1):119-124. GUO Xiang. Research on gas emission law and control technology of “isolated island” variable-length working face[J]. Coal Science and Technology,2022,50(S1):119-124.

[4] 张开加,倪兴. 东兴煤矿顺层抽采钻孔分段水力冲孔技术研究[J]. 煤炭工程,2023,55(3):73-77. ZHANG Kaijia,NI Xing. Segmented hydraulic punching technology of bedding borehole in Dongxing Coal Mine[J]. Coal Engineering,2023,55(3):73-77.

[5] 马彦阳,吴教锟,冯仁俊,等. 坚硬顶板定向长钻孔水力压裂卸压瓦斯抽采研究[J]. 矿业安全与环保,2022,49(6):52-56. MA Yanyang,WU Jiaokun,FENG Renjun,et al. Pressure relief gas drainage by directional drilling hydraulic fracturing in hard roof[J]. Mining Safety & Environmental Protection,2022,49(6):52-56.

[6] 李晓绅,刘瑞鹏. 含夹矸煤层水力割缝瓦斯抽采技术研究及应用[J]. 工矿自动化,2023,49(4):134-140. LI Xiaoshen,LIU Ruipeng. Research and application of hydraulic slotting gas extraction technology in coal seams containing gangue[J]. Journal of Mine Automation,2023,49(4):134-140.

[7] 梁卫国,张倍宁,黎力,等. 注能(以CO2为例)改性驱替开采CH4理论与实验研究[J]. 煤炭学报,2018,43(10):2839-2847. LIANG Weiguo,ZHANG Beining,LI Li,et al. Theory and experimental study of CBM recovery driven by energy boosting[J]. Journal of China Coal Society,2018,43(10):2839-2847.

[8] 杨宏民,冯朝阳,陈立伟. 煤层注氮模拟实验中的置换−驱替效应及其转化机制分析[J]. 煤炭学报,2016,41(9):2246-2250. YANG Hongmin,FENG Zhaoyang,CHEN Liwei. Analysis of replacement-displacement effect and its change mechanism in simulation experiment of nitrogen injection into coal seam[J]. Journal of China Coal Society,2016,41(9):2246-2250.

[9] 杨宏民,冯朝阳,陈立伟. 不同注氮压力置驱煤层甲烷试验中的机理分析[J]. 煤矿安全,2017,48(2):145-148. YANG Hongmin,FENG Zhaoyang,CHEN Liwei. Mechanism analysis on experiment of injecting nitrogen to displace coal seam methane under different pressure[J]. Safety in Coal Mines,2017,48(2):145-148.

[10] 耿晓伟,阎晶雪. 注气条件对CO2置换驱替CH4影响的实验研究[J]. 中国安全生产科学技术,2021,17(11):79-84. GENG Xiaowei,YAN Jingxue. Experimental study on influence of gas injection conditions on CO2 replacement and displacement of CH4[J]. Journal of Safety Science and Technology,2021,17(11):79-84.

[11] 姜延航,白刚,周西华,等. 煤层注CO2驱替CH4影响因素试验研究[J]. 中国安全科学学报,2022,32(4):113-121. JIANG Yanhang,BAI Gang,ZHOU Xihua,et al. Experimental study on influence factors of CH4 displacement by CO2[J]. China Safety Science Journal,2022,32(4):113-121.

[12] 宋鑫,舒龙勇,王斌,等. 低瓦斯赋存高强度开采煤层驱替促抽技术研究[J]. 采矿与安全工程学报,2023,40(4):847-856. SONG Xin,SHU Longyong,WANG Bin,et al. Replacement and pumping technology for coal seams with low gas content and high intensity mining[J]. Journal of Mining & Safety Engineering,2023,40(4):847-856.

[13] 王公达,陈善文,孙峰,等. 抽采衰竭期注气增压强采欠压瓦斯技术研究[J]. 煤炭科学技术,2021,49(8):125-130. WANG Gongda,CHEN Shanwen,SUN Feng,et al. Study on technology of gas flushing unsaturated gas during drainage exhaustion period[J]. Coal Science and Technology,2021,49(8):125-130.

[14] XU Wenjie,ZHENG Xigui,LIU Cancan,et al. Numerical simulation study of high-pressure air injection to promote gas drainage[J]. Sustainability,2022,14(21):13699. DOI: 10.3390/su142113699

[15] 贾进章,张天阔,王东明,等. 注二氧化碳促抽煤层瓦斯数值模拟及现场试验[J]. 安全与环境工程,2023,30(1):78-86. JIA Jinzhang,ZHANG Tiankuo,WANG Dongming,et al. Numerical simulation and field test of CO2 injection to promote coal seam gas extraction[J]. Safety and Environmental Engineering,2023,30(1):78-86.

[16] 李志强,王兆丰. 井下注气强化煤层气抽采效果的工程试验与数值模拟[J]. 重庆大学学报,2011,34(4):72-77,82. LI Zhiqiang,WANG Zhaofeng. Test and numerical simulation on effect of enhanced coalbed methane drawing by injecting gas under coal mine[J]. Journal of Chongqing University,2011,34(4):72-77,82.

[17] 李元星. 连续与间歇注空气驱替煤层气机理及实验研究[D]. 太原:太原理工大学,2017. LI Yuanxing. Mechanism and experimental research on coalbed methane displacement by continuous and intermittent air injection[J]. Taiyuan:Taiyuan University of Technology,2017.

[18] FAN Yongpeng,DENG Cunbao,ZHANG Xun,et al. Numerical study of CO2-enhanced coalbed methane recovery[J]. International Journal of Greenhouse Gas Control,2018,76:12-23. DOI: 10.1016/j.ijggc.2018.06.016

[19] 张浩浩,李胜,高宏,等. 平煤十矿底板巷穿层钻孔瓦斯抽采模拟研究[J]. 中国安全生产科学技术,2018,14(9):38-43. ZHANG Haohao,LI Sheng,GAO Hong,et al. Simulation study on gas extraction by drilling borehole passed through coal seam in floor roadway in Pingdingshan No.10 Mine[J]. Journal of Safety Science and Technology,2018,14(9):38-43.

[20] 龙泳翰,张磊,李菁华,等. 注气驱替机理研究现状及展望[J]. 矿业安全与环保,2023,50(1):103-108,114. LONG Yonghan,ZHANG Lei,LI Jinghua,et al. Research status and prospect of gas injection displacement mechanism[J]. Mining Safety & Environmental Protection,2023,50(1):103-108,114.

[21] DAY S,FRY R,SAKUROVS R,et al. Swelling of coals by supercritical gases and its relationship to sorption[J]. Energy & Fuels,2010,24(4):2777-2783.

[22] ZHU Wancheng,LIU Jishan,QU Hongyan,et al. A model of coal–gas interaction under variable temperatures[J]. International Journal of Coal Geology,2011,86(2/3):213-221.

[23] 郑学召,黄渊,文虎,等. 不同注气压力下CO2驱替置换CH4试验研究[J]. 工矿自动化,2021,47(4):73-78. ZHENG Xuezhao,HUANG Yuan,WEN Hu,et al. Experimental study of CO2 replacement for CH4 at different gas injection pressures[J]. Industry and Mine Automation,2021,47(4):73-78.

[24] 撒占友,吴静波,杨永亮,等. 考虑Klinkenberg因子状态的CO2−ECBM模拟研究[J]. 煤田地质与勘探,2023,51(3):37-45. DOI: 10.12363/issn.1001-1986.22.09.0713 SA Zhanyou,WU Jingbo,YANG Yongliang,et al. CO2-ECBM simulation study considering Klinkenberg factor state[J]. Coal Geology & Exploration,2023,51(3):37-45. DOI: 10.12363/issn.1001-1986.22.09.0713

[25] 马砺,李珍宝,邓军,等. 常压下煤对N2/CO2/CH4单组分气体吸附特性研究[J]. 安全与环境学报,2015,15(2):64-67. MA Li,LI Zhenbao,DENG Jun,et al. On the characteristic features of the adsorption capacity of the coal for the singular component gases of CH4,CO2,N2 under regular pressures[J]. Journal of Safety and Environment,2015,15(2):64-67.

[26] 武司苑,邓存宝,戴凤威,等. 煤吸附CO2、O2和N2的能力与竞争性差异[J]. 环境工程学报,2017,11(7):4229-4235. DOI: 10.12030/j.cjee.201605044 WU Siyuan,DENG Cunbao,DAI Fengwei,et al. Differences of ability and competitiveness on coal adsorbing CO2,O2 and N2[J]. Chinese Journal of Environmental Engineering,2017,11(7):4229-4235. DOI: 10.12030/j.cjee.201605044

-

期刊类型引用(10)

1. 刘康宁,杨国志,王鹏博,朱亚东,代阳. 基于数字孪生技术的智能巡检小车和UWB定位设计. 电子设计工程. 2025(04): 66-72 .  百度学术

百度学术

2. 王忠宾,司垒,魏东,戴剑博,顾进恒,邹筱瑜,张聪,闫海峰,谭超. 煤矿防冲钻孔机器人全自主钻进系统关键技术. 煤炭学报. 2024(02): 1240-1258 .  百度学术

百度学术

3. 刘清,刘军锋. 基于UWB的综采工作面推进度测量系统. 工矿自动化. 2024(04): 33-40 .  本站查看

本站查看

4. 钱正峰,陈代伟,胡峰平,付云飞. 基于UWB技术的标识卡搜索仪技术研究. 机械工程与自动化. 2024(04): 173-174 .  百度学术

百度学术

5. 王国庆,赵鑫,杨春雨,马磊,代伟. 煤矿地下空间定位技术研究进展. 工程科学学报. 2024(10): 1713-1727 .  百度学术

百度学术

6. 马伟佳,范玫杉,徐冠宇. 煤矿机器人研究进展、关键技术及发展趋势. 机器人技术与应用. 2024(04): 3-10 .  百度学术

百度学术

7. 岳蕾. 基于PSO改进算法的煤矿井下精确UWB技术研究. 粘接. 2024(10): 129-132 .  百度学术

百度学术

8. 孙逍远,薄煜明. 基于多视觉传感器的矿井移动机器人目标定位模型研究. 金属矿山. 2024(11): 199-204 .  百度学术

百度学术

9. 马宏伟,苏浩,薛旭升,李超,郭逸风,王星,周文剑,崔闻达,喻祖坤,成佳帅. 煤矿井下移动机器人激光标靶定位方法研究. 煤炭科学技术. 2024(11): 60-73 .  百度学术

百度学术

10. 毕松,张国轩,李志军,胡福文. 基于测距值修正的温室植保机器人定位方法. 农业机械学报. 2023(08): 347-358 .  百度学术

百度学术

其他类型引用(4)

下载:

下载: