Research on intelligent mine disaster digital twin based on industrial Internet

-

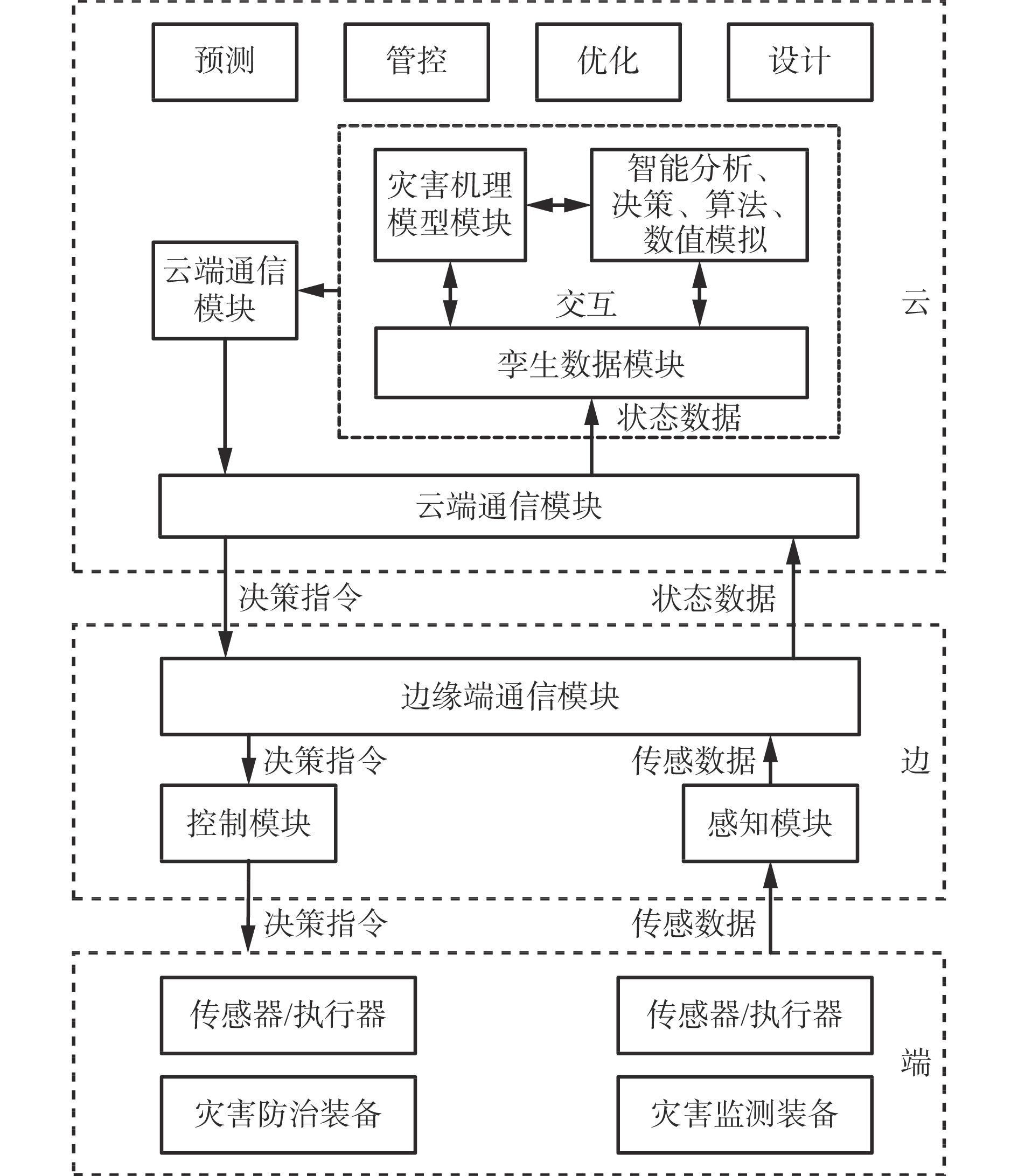

摘要: 煤矿灾害综合管控是智能矿山建设进程中需要重点解决的难题,借助数字孪生技术实现煤矿灾害的常态化管控是智能矿山建设的必然要求。从数字孪生内涵及本质出发,分析了数字孪生认识规律,并结合煤矿灾害数字孪生数据交互流程,提出了数字孪生技术在煤矿灾害研究中的应用模式:通过煤矿井下灾害监测传感器等设备进行实时监测,将监测数据通过边缘通信模块、云端通信模块上传至云端;数字孪生数值仿真软件部署在云端,利用传感器上传的监测数据作为初始条件参数、边界条件参数、效果验证参数,经过实时仿真分析,通过不断试错,寻求最佳的优化参数及解决方案;当技术手段在孪生世界应用成熟后,可用于对虚拟实体的最佳参数、解决方案等进行分析、判断、决策,并下发决策指令至井下执行器,控制灾害防治装备动作。从灾害监测方案优化、灾害预演及避灾路线精准规划、灾后救援方案制订及事故调查3个方面探讨了数字孪生赋能灾害预测性管控的实际应用。以工业互联网“云−管−边−端”架构为基础,构建了煤矿灾害数字孪生服务体系,并分析了面向矿山灾害的数字孪生关键技术,包括煤矿灾害智能感知和执行装备、煤矿灾害仿真软件、共性支撑技术,以期为数字孪生赋能智能矿山建设提供参考。Abstract: The comprehensive control of coal mine disasters is a key problem to be solved in the process of intelligent mine construction. It is an inevitable requirement for the construction of intelligent mines to realize the normalization control of coal mine disasters with the help of digital twin technology. Based on the connotation and essence of the digital twin, this paper analyzes the recognition rule of the digital twin and puts forward the application mode of digital twin technology in coal mine disaster research combining with data interactive process of mine disaster digital twin. Real-time monitoring is carried out by coal mine underground disaster monitoring sensor. The monitoring data is uploaded to the cloud through the edge communication module and cloud communication module. The digital twin numerical simulation software is deployed in the cloud. The monitoring data uploaded by the sensor is used as the initial condition parameter, boundary condition parameter and effect verification parameter. The best optimization parameters and solutions are sought through real-time simulation analysis and continuous trial and error. When the technical means are mature in the twin world, they can be used to analyze, judge and make decisions on the best parameters and solutions for virtual entities. The decision instructions can be sent to underground actuators to control the action of disaster prevention equipment. This paper discusses the practical application of digital twin enabling disaster predictive management and control from three aspects: disaster monitoring scheme optimization, disaster rehearsal and precise planning of disaster avoidance route, and post-disaster rescue scheme formulation and accident investigation. Based on the "cloud-pipe-edge-end" architecture of the industrial Internet, the digital twin service system for coal mine disasters is constructed. The key technologies of digital twin for mine disasters are analyzed. The technologies include intelligent sensing and execution equipment for coal mine disasters, simulation software for coal mine disasters and common support technologies. It is expected to provide reference for the construction of digital twin-enabling intelligent mines.

-

编者按:煤炭行业数字化、智能化发展是实现煤炭工业高质量发展的强大动力。然而,传统的数字矿山等概念不足以体现新一代数字技术应用的趋势。当前,数字孪生技术日趋成为工业界的应用热点,被认为是推动企业数字化转型快速有效的通用技术。在矿山领域引入数字孪生技术,能够推动煤炭行业向真正的智能化方向转变,为探索可持续发展的智慧矿山建设提供新的思路。为促进数字孪生与虚拟现实技术在矿山领域的应用研究,《工矿自动化》编辑部于2023年第2期组织出版“智慧矿山数字孪生与虚拟现实技术”专题。在专题刊出之际,衷心感谢各位专家学者的大力支持!

-

[1] 王国法,庞义辉,李爽,等. 基于煤矿时空多源信息感知的智能安控闭环体系[J]. 矿业安全与环保,2022,49(4):1-11. WANG Guofa,PANG Yihui,LI Shuang,et al. Intelligent safety closed-loop management and control system based on multi-source information perception in coal mine[J]. Mining Safety & Environmental Protection,2022,49(4):1-11.

[2] 张庆华,马国龙. 我国煤矿重大灾害预警技术现状及智能化发展展望[J]. 智能矿山,2020,1(1):52-62. ZHANG Qinghua,MA Guolong. Status and intelligent development prospect of coal mine major disaster early-warning technology in China[J]. Journal of Intelligent Mine,2020,1(1):52-62.

[3] 袁亮. 深部采动响应与灾害防控研究进展[J]. 煤炭学报,2021,46(3):716-725. DOI: 10.13225/j.cnki.jccs.YT21.0158 YUAN Liang. Research progress of mining response and disaster prevention and control in deep coal mines[J]. Journal of China Coal Society,2021,46(3):716-725. DOI: 10.13225/j.cnki.jccs.YT21.0158

[4] 窦林名,田鑫元,曹安业,等. 我国煤矿冲击地压防治现状与难题[J]. 煤炭学报,2022,47(1):152-171. DOU Linming,TIAN Xinyuan,CAO Anye,et al. Present situation and problems of coal mine rock burst prevention and control in China[J]. Journal of China Coal Society,2022,47(1):152-171.

[5] 王文婕,张淑含. 深部开采矿井地热能开发与热害协同防治技术[J]. 煤炭与化工,2022,45(9):87-90. WANG Wenjie,ZHANG Shuhan. Cooperative prevention and control technology of geothermal energy development and thermal damage in deep mining mines[J]. Coal and Chemical Industry,2022,45(9):87-90.

[6] 姜涛,崔嵛,刘国磊,等. 通风和开口形状对地下硐室火灾影响的实验研究[J]. 中国安全生产科学技术,2020,16(2):67-72. JIANG Tao,CUI Yu,LIU Guolei,et al. Experimental study on influence of ventilation and opening shape on underground chamber fire[J]. Journal of Safety Science and Technology,2020,16(2):67-72.

[7] 景国勋,吴昱楼,郭绍帅,等. 障碍物对瓦斯煤尘爆炸火焰传播规律的影响[J]. 中国安全生产科学技术,2019,15(9):99-104. JING Guoxun,WU Yulou,GUO Shaoshuai,et al. Influence of obstacle on flame propagation laws of gas and coal dust explosion[J]. Journal of Safety Science and Technology,2019,15(9):99-104.

[8] 李晴,康建宏,周福宝,等. 全尺寸巷/隧道火灾风烟流温度预测模型与验证[J]. 中国安全生产科学技术,2022,18(8):5-12. LI Qing,KANG Jianhong,ZHOU Fubao,et al. Prediction model and verification of smoke flow temperature in full-scale roadway/tunnel fires[J]. Journal of Safety Science and Technology,2022,18(8):5-12.

[9] 姚勇征,张文明,吴兵,等. 巷道火灾对通风系统影响的全尺寸实验与模拟[J]. 中国矿业大学学报,2021,50(4):709-715. DOI: 10.13247/j.cnki.jcumt.001306 YAO Yongzheng,ZHANG Wenming,WU Bing,et al. Full-scale experimental and simulation study of the influences of laneway fire on ventilation system[J]. Journal of China University of Mining & Technology,2021,50(4):709-715. DOI: 10.13247/j.cnki.jcumt.001306

[10] 胡晓伟. 矿井安全应急救援体系存在问题分析及完善措施[J]. 中国矿山工程,2020,49(6):64-66. DOI: 10.3969/j.issn.1672-609X.2020.06.019 HU Xiaowei. Problems analysis and improvement measures of mine safety emergency rescue system[J]. China Mine Engineering,2020,49(6):64-66. DOI: 10.3969/j.issn.1672-609X.2020.06.019

[11] 郭军,蔡国斌,郑学召,等. 矿井热动力灾害及救援安全性判定研究现状及展望[J]. 煤炭科学技术,2020,48(12):116-122. DOI: 10.13199/j.cnki.cst.2020.12.014 GUO Jun,CAI Guobin,ZHENG Xuezhao,et al. Research status and prospect of mine thermal disaster and rescue safety judgement[J]. Coal Science and Technology,2020,48(12):116-122. DOI: 10.13199/j.cnki.cst.2020.12.014

[12] 邢震. 浅埋厚煤层地表漏风对采空区煤自燃影响数值模拟研究[J]. 工矿自动化,2021,47(2):80-87,103. DOI: 10.13272/j.issn.1671-251x.2020100018 XING Zhen. Numerical simulation study on the influence of surface air leakage in shallow thick coal seam on coal spontaneous combustion in goaf[J]. Industry and Mine Automation,2021,47(2):80-87,103. DOI: 10.13272/j.issn.1671-251x.2020100018

[13] 邢震. 特厚煤层自燃关键参数现场观测及动态数值模拟研究[J]. 煤炭工程,2020,52(2):111-115. XING Zhen. In-situ observation and dynamic numerical simulation research on the key parameters of extra-thick coal seam spontaneous combustion[J]. Coal Engineering,2020,52(2):111-115.

[14] 王国法. 煤矿智能化最新技术进展与问题探讨[J]. 煤炭科学技术,2022,50(1):1-27. DOI: 10.3969/j.issn.0253-2336.2022.1.mtkxjs202201001 WANG Guofa. New technological progress of coal mine intelligence and its problems[J]. Coal Science and Technology,2022,50(1):1-27. DOI: 10.3969/j.issn.0253-2336.2022.1.mtkxjs202201001

[15] 王国法,任怀伟,赵国瑞,等. 煤矿智能化十大“痛点”解析及对策[J]. 工矿自动化,2021,47(6):1-11. DOI: 10.13272/j.issn.1671-251x.17808 WANG Guofa,REN Huaiwei,ZHAO Guorui,et al. Analysis and countermeasures of ten 'pain points' of intelligent coal mine[J]. Industry and Mine Automation,2021,47(6):1-11. DOI: 10.13272/j.issn.1671-251x.17808

[16] 郎为民,马卫国,赵卓萍,等. 数字孪生系统构成研究[J]. 电信快报,2022(9):1-5. DOI: 10.3969/j.issn.1006-1339.2022.09.001 LANG Weimin,MA Weiguo,ZHAO Zhuoping,et al. Research on the composition of digital twin system[J]. Telecommunications Information,2022(9):1-5. DOI: 10.3969/j.issn.1006-1339.2022.09.001

[17] 陶飞,马昕,胡天亮,等. 数字孪生标准体系[J]. 计算机集成制造系统,2019,25(10):2405-2418. DOI: 10.13196/j.cims.2019.10.001 TAO Fei,MA Xin,HU Tianliang,et al. Research on digital twin standard system[J]. Computer Integrated Manufacturing Systems,2019,25(10):2405-2418. DOI: 10.13196/j.cims.2019.10.001

[18] 陶飞,刘蔚然,张萌,等. 数字孪生五维模型及十大领域应用[J]. 计算机集成制造系统,2019,25(1):1-18. DOI: 10.13196/j.cims.2019.01.001 TAO Fei,LIU Weiran,ZHANG Meng,et al. Five-dimension digital twin model and its ten applications[J]. Computer Integrated Manufacturing Systems,2019,25(1):1-18. DOI: 10.13196/j.cims.2019.01.001

[19] 李爽,贺超,薛广哲. 以双重预防机制实现智能矿山愿景 用灾害综合防治系统保障智能矿山安全[J]. 智能矿山,2022,3(6):87-92. LI Shuang,HE Chao,XUE Guangzhe. Realize the vision of intelligent mine with dual prevention mechanism and ensure the safety of intelligent mine with comprehensive disaster prevention system[J]. Journal of Intelligent Mine,2022,3(6):87-92.

[20] 邢震. 高瓦斯矿井采空区瓦斯与煤自燃耦合规律研究[J]. 工矿自动化,2020,46(3):6-11,20. DOI: 10.13272/j.issn.1671-251x.2019010084 XING Zhen. Research on coupling law of gas and coal spontaneous combustion in goaf of high gas mine[J]. Industry and Mine Automation,2020,46(3):6-11,20. DOI: 10.13272/j.issn.1671-251x.2019010084

[21] 李雷雷,丁晓文,梁跃强,等. 基于灾区环境的矿井瓦斯爆炸事故应急救援方法研究[J]. 煤矿安全,2022,53(1):237-242. LI Leilei,DING Xiaowen,LIANG Yueqiang,et al. Emergency rescue method based on disaster area environment of gas explosion in underground coal mines[J]. Safety in Coal Mines,2022,53(1):237-242.

[22] 郎为民,田尚保,李宇鸽,等. 数字孪生技术架构研究[J]. 电信快报,2022(8):1-6. DOI: 10.3969/j.issn.1006-1339.2022.08.001 LANG Weimin,TIAN Shangbao,LI Yuge,et al. Research on the technical architecture of digital twin[J]. Telecommunications Information,2022(8):1-6. DOI: 10.3969/j.issn.1006-1339.2022.08.001

[23] 葛世荣,王世博,管增伦,等. 数字孪生−应对智能化综采工作面技术挑战[J]. 工矿自动化,2022,48(7):1-12. GE Shirong,WANG Shibo,GUAN Zenglun,et al. Digital twin:meeting the technical challenges of intelligent fully mechanized working face[J]. Journal of Mine Automation,2022,48(7):1-12.

[24] 丁恩杰,俞啸,夏冰,等. 矿山信息化发展及以数字孪生为核心的智慧矿山关键技术[J]. 煤炭学报,2022,47(1):564-578. DING Enjie,YU Xiao,XIA Bing,et al. Development of mine informatization and key technologies of intelligent mines[J]. Journal of China Coal Society,2022,47(1):564-578.

[25] 张帆,葛世荣,李闯. 智慧矿山数字孪生技术研究综述[J]. 煤炭科学技术,2020,48(7):168-176. DOI: 10.13199/j.cnki.cst.2020.07.017 ZHANG Fan,GE Shirong,LI Chuang. Research summary on digital twin technology for smart mines[J]. Coal Science and Technology,2020,48(7):168-176. DOI: 10.13199/j.cnki.cst.2020.07.017

[26] 孟峰,张磊,赵子未,等. 基于物联网的智能传感器技术及其应用[J]. 工矿自动化,2021,47(增刊1):48-50. MENG Feng,ZHANG Lei,ZHAO Ziwei,et al. Application of intelligent sensor technology based on Internet of things[J]. Industry and Mine Automation,2021,47(S1):48-50.

[27] 程晓涵,李宗吾,谢秉沁,等. 基于MEMS技术的矿用无线传感采集系统设计[J]. 煤炭工程,2022,54(3):26-32. CHENG Xiaohan,LI Zongwu,XIE Bingqin,et al. MEMS technology-based mine wireless sensor acquisition system[J]. Coal Engineering,2022,54(3):26-32.

[28] 田忠斌,马玉龙,李貅,等. 煤层采空区内煤层气储气构造半航空瞬变电磁探测——以沁水煤田为例[J]. 地球物理学报,2022,65(11):4495-4503. DOI: 10.6038/cjg2022P0799 TIAN Zhongbin,MA Yulong,LI Xiu,et al. A method for detecting coalbed methane gas storage structure in coal goaf:a case in Qinshui Coal Field in Shanxi Province[J]. Chinese Journal of Geophysics,2022,65(11):4495-4503. DOI: 10.6038/cjg2022P0799

[29] 邢震. 综放工作面采空区自燃危险区域监测技术及应用研究[J]. 煤炭工程,2017,49(11):130-132,137. XING Zhen. Research on monitoring technology for danger zone of spontaneous combustion in goaf of fully-mechanized top-coal caving face[J]. Coal Engineering,2017,49(11):130-132,137.

[30] 董洪凯. 区域瓦斯抽采空白带耦合模拟研究[J]. 煤炭技术,2016,35(8):216-218. DOI: 10.13301/j.cnki.ct.2016.08.089 DONG Hongkai. Coupling simulation study on local gas drainage blank tape[J]. Coal Technology,2016,35(8):216-218. DOI: 10.13301/j.cnki.ct.2016.08.089

[31] 陆卫东,程刚. 基于FLAC3D的急倾斜特厚煤层水平分层开采围岩应力分析[J]. 煤矿安全,2016,47(1):200-203. LU Weidong,CHENG Gang. Surrounding rock stress analysis for horizontal slicing of steeply inclined and extremely thick coal seam based on FLAC3D[J]. Safety in Coal Mines,2016,47(1):200-203.

[32] 谢旭阳,闫学文,杜红兵,等. 面向对象技术在矿井火灾模拟中的应用[J]. 煤矿安全,2001,32(8):41-42. DOI: 10.3969/j.issn.1003-496X.2001.08.019 XIE Xuyang,YAN Xuewen,DU Hongbing,et al. Application of object-oriented technology in mine fire simulation[J]. Safety in Coal Mines,2001,32(8):41-42. DOI: 10.3969/j.issn.1003-496X.2001.08.019

[33] 肖梦辉,于涛,常宝孟,等. 基于Ventsim的复杂矿井火灾数值模拟研究[J]. 矿业研究与开发,2021,41(12):129-134. DOI: 10.13827/j.cnki.kyyk.2021.12.009 XIAO Menghui,YU Tao,CHANG Baomeng,et al. Numerical simulation study on complex mine fire based on Ventsim[J]. Mining Research and Development,2021,41(12):129-134. DOI: 10.13827/j.cnki.kyyk.2021.12.009

[34] 陈晓晶.基于“云−边−端”协同的煤矿火灾智能化防控建设思路探讨[J/OL].煤炭科学技术:1-9[2022-10-10]. DOI:10.13199/j.cnki.cst.2021-0488. CHEN Xiaojing. Discussion on the construction of intelligent prevention and control of coal mine fire based on "cloud-edge-end" cooperation[J]. Coal Science and Technology:1-9[2022-10-10]. DOI:10.13199/j.cnki.cst.2021-0488.

[35] 刘昕,付元,李晨鑫. 5G特性在智慧矿山中的应用研究[J]. 工矿自动化,2022,48(10):136-141. LIU Xin,FU Yuan,LI Chenxin. Research on the application of 5G characteristics in intelligent mine[J]. Journal of Mine Automation,2022,48(10):136-141.

[36] 王翀,陈佳林. 煤矿物联网大数据平台设计与关键技术研究[J]. 中国煤炭,2022,48(3):42-49. DOI: 10.3969/j.issn.1006-530X.2022.03.007 WANG Chong,CHEN Jialin. Research on design and key technology of big data platform of coal mine Internet of things[J]. China Coal,2022,48(3):42-49. DOI: 10.3969/j.issn.1006-530X.2022.03.007

-

期刊类型引用(6)

1. 冯卫国. 5G技术在煤矿智能化中的应用. 能源与节能. 2025(02): 238-240+250 .  百度学术

百度学术

2. 王周,张涛,薛成冰,陈强,王涛. 5G通信技术在智能化煤矿的应用研究. 数字通信世界. 2024(05): 108-110 .  百度学术

百度学术

3. 宇迪,王丹阳,柳汀. 基于产运销储用一体化综合模型的研究. 煤炭经济研究. 2024(05): 150-158 .  百度学术

百度学术

4. 罗武军,刘道园,杨云博. 融合5G通信的煤矿井下作业现代化方案设计及优化. 煤炭技术. 2024(10): 256-260 .  百度学术

百度学术

5. 赵国志,于建辉,许艳云,陈佳雨,宋杰,薛胜利. 5G技术在智能化煤矿中的应用. 数字通信世界. 2024(09): 160-162 .  百度学术

百度学术

6. 熊俊. 基于5G传输的矿用电缆绝缘监测技术研究. 电工技术. 2024(19): 213-217+224 .  百度学术

百度学术

其他类型引用(2)

下载:

下载: