Face pressure identification method based on intelligent detection of coal cutting cycles

-

摘要:

基于液压支架工作阻力数据进行工作面来压判识需解决2个问题:一是如何从海量的工作阻力数据中提取循环末阻力数据,二是如何有效利用提取出的循环末阻力数据对工作面是否来压实现有效判断。现有的循环末阻力提取方法大多依赖固定规则和经验值参数,在复杂工作面环境下准确性低且适应性差。针对该问题,提出一种基于割煤循环智能检测的工作面来压判识方法。将割煤循环检测转化为二分类问题,使用支持向量机分类器对割煤循环结束时刻进行智能检测,以自动判别割煤循环的结束时刻;在获取所有割煤循环结束时刻的基础上,提取各支架循环末阻力数据;通过数据融合生成能够反映工作面整体压力状态的单序列数据,并基于来压判定公式进行工作面来压判识。基于不连沟煤矿某工作面的液压支架工作阻力数据进行实验,结果表明,该方法割煤循环检测的精确率、召回率、F1分数分别为85.91%,81.84%,83.83%,来压判识的精确率、召回率、F1分数分别为79.43%,78.76%,79.09%,均优于滑动窗口极值法和阈值法,在识别循环末阻力和工作面来压判识方面具有显著优势。

Abstract:The method for identifying face pressure based on hydraulic support working resistance data needs to address two issues: first, how to extract the cycle-end resistance data from large volumes of working resistance data, and second, how to effectively utilize the extracted cycle-end resistance data to determine whether face pressure is occurring. Most existing methods for extracting cycle-end resistance rely on fixed rules and empirical parameter values, which have low accuracy and poor adaptability in complex working face environments. To address this issue, an intelligent detection method for face pressure identification based on coal cutting cycles was proposed. Coal cutting cycle detection was transformed into a binary classification problem, using a support vector machine (SVM) classifier to intelligently detect the end time of coal cutting cycles, automatically identifying the end of each coal cutting cycle. After obtaining the end times of all coal cutting cycles, the cycle-end resistance data for each support was extracted. Data fusion was performed to generate a single sequence of data that reflects the overall pressure state of the working face. Face pressure identification was then made based on a pressure judgment formula. Experiments were conducted on hydraulic support working resistance data from a working face in a non-contiguous coal mine. The results showed that the proposed method had precision, recall, and F1 scores of 85.91%, 81.84%, and 83.83%, respectively, for coal cutting cycle detection, and precision, recall, and F1 scores of 79.43%, 78.76%, and 79.09%, respectively, for face pressure identification These results are superior to the sliding window extreme value method and threshold method, demonstrating significant advantages in cycle-end resistance identification and face pressure judgment.

-

-

表 1 割煤循环检测实验结果

Table 1 Experimental results of coal cutting cycle detection

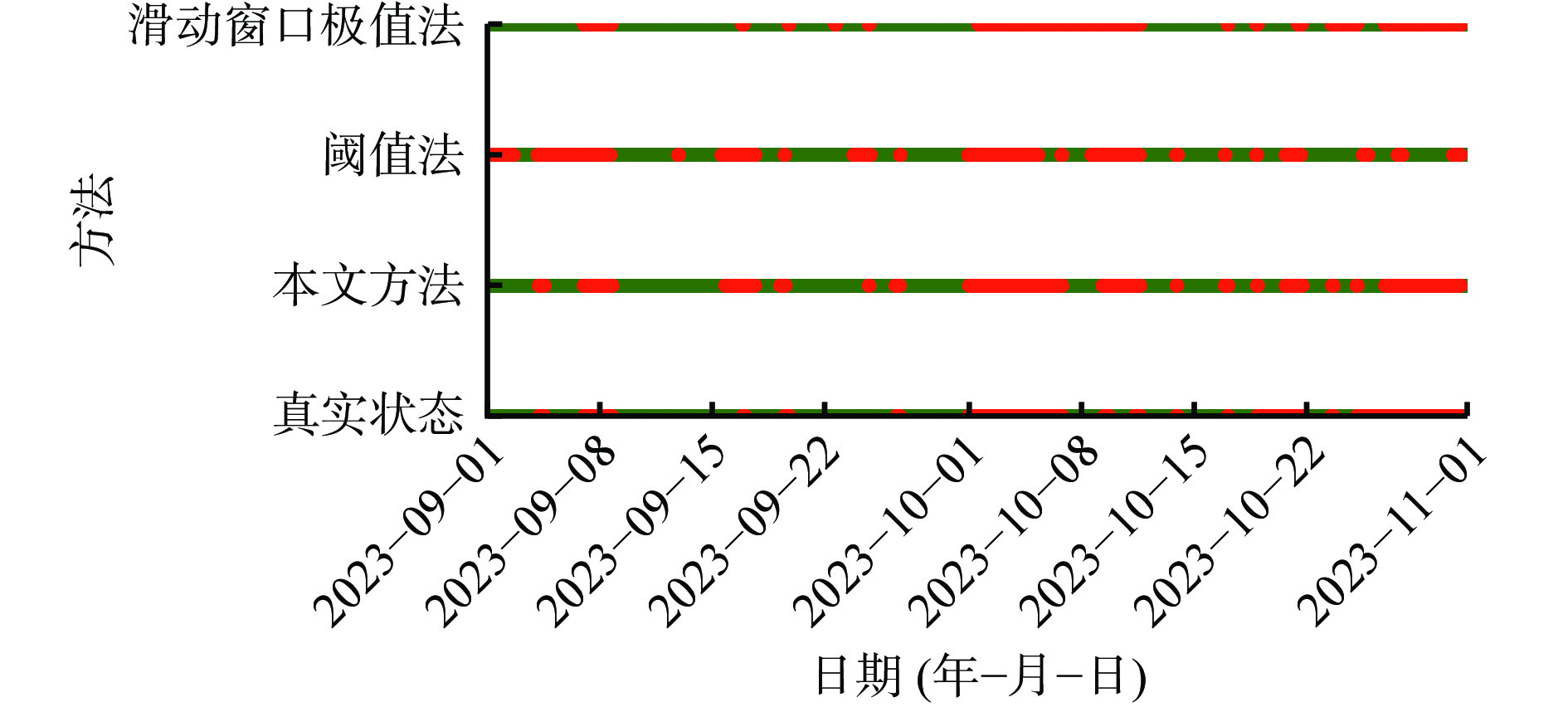

% 方法 精确率 召回率 F1分数 滑动窗口极值法 57.89 55.13 56.48 阈值法 82.86 55.99 66.83 本文方法 85.91 81.84 83.83 表 2 来压判识实验结果

Table 2 Experimental results of face pressure identification %

方法 精确率 召回率 F1分数 滑动窗口极值法 77.59 76.68 77.13 阈值法 64.46 65.12 64.79 本文方法 79.43 78.76 79.09 -

[1] 罗香玉,杜浩,华颖,等. 一种煤矿顶板灾害防治知识图谱构建方法[J]. 工矿自动化,2024,50(6):54-60. LUO Xiangyu,DU Hao,HUA Ying,et al. A method for constructing a knowledge graph of coal mine roof disaster prevention and control[J]. Journal of Mine Automation,2024,50(6):54-60.

[2] 赵亚军,张志男,贾廷贵. 2010—2021年我国煤矿安全事故分析及安全对策研究[J]. 煤炭技术,2023,42(8):128-131. ZHAO Yajun,ZHANG Zhinan,JIA Tinggui. Analysis of coal mine safety accidents and research on safety countermeasures in China from 2010 to 2021[J]. Coal Technology,2023,42(8):128-131.

[3] 赵丽娟,李迎,吕文陵,等. 基于灰色关联分析法的煤矿顶板事故研究及防治[J]. 矿业安全与环保,2024,51(6):54-62. ZHAO Lijuan,LI Ying,LYU Wenling,et al. Research and prevention of coal mine roof accident based on grey correlation analysis[J]. Mining Safety & Environmental Protection,2024,51(6):54-62.

[4] 王昊,李杰,郑闯凯,等. 煤矿采场顶板灾害预警技术研究进展及展望[J]. 矿业安全与环保,2024,51(2):46-52. WANG Hao,LI Jie,ZHENG Chuangkai,et al. Research progress and prospect of early warning technology of coal mine stope roof disaster[J]. Mining Safety & Environmental Protection,2024,51(2):46-52.

[5] 李宏扬. 液压支架加载形式研究及其强度分析[D]. 阜新:辽宁工程技术大学,2022. LI Hongyang. Study of hydraulic support loading form and its strength analysis[D]. Fuxin:Liaoning Technical University,2022.

[6] 吴士良,杨路林. 支架工作阻力大数据分析系统[J]. 工矿自动化,2017,43(11):86-89. WU Shiliang,YANG Lulin. Big data analysis system of working resistance of support[J]. Industry and Mine Automation,2017,43(11):86-89.

[7] 中煤科工集团重庆研究院有限公司. 基于综采工作面液压支架压力数据的周期来压判识方法:CN202411270215.5[P]. 2024-09-11. CCTEG Chongqing Research Institute. Method for pressure judgment based on the cycle of hydraulic support pressure data in comprehensive mining working face:CN202411270215.5[P]. 2024-09-11.

[8] 余琼芳,杨鹏飞,唐高峰. 基于LSTM-Informer模型的液压支架压力时空多步长预测[J]. 工矿自动化,2024,50(6):30-35. YU Qiongfang,YANG Pengfei,TANG Gaofeng. Spatiotemporal multi-step prediction of hydraulic support pressure based on LSTM-Informer model[J]. Journal of Mine Automation,2024,50(6):30-35.

[9] 王志奎. 基于支架工作阻力大数据的工作面区域矿压预测技术研究[D]. 青岛:山东科技大学,2018. WANG Zhikui. Research on prediction technology of mining area pressure based on large data of support working resistance[D]. Qingdao:Shandong University of Science and Technology,2018.

[10] 连东辉,袁瑞甫,崔科飞,等. 综采工作面自动化生产工艺研究与应用 [J/OL]. 煤炭科学技术:1-11[2024-11-24]. http://kns.cnki.net/kcms/detail/11.2402.TD.20240613.1512.005.html. LIAN Donghui,YUAN Ruifu,CUI Kefei,et al. Research and application of automatic production technology of fully mechanized Longwall working face for complex condition coal seam[J/OL]. Coal Science and Technology:1-11[2024-11-24]. http://kns. cnki.net/kcms/detail/11.2402.TD.20240613.1512.005.html.

[11] 冯银辉,宋阳,李务晋,等. 基于支架数据优化的工作面矿压预测模型研究[J]. 煤炭工程,2023,55(6):101-107. FENG Yinhui,SONG Yang,LI Wujin,et al. Mine pressure prediction model for fully mechanized working face based on data optimization of hydraulic support[J]. Coal Engineering,2023,55(6):101-107.

[12] 卢国志,胡斐,李鑫,等. 液压支架实时压力数据自动提取与动态分析方法研究[J]. 煤炭工程,2023,55(3):120-126. LU Guozhi,HU Fei,LI Xin,et al. A method for automatic extraction and dynamic analysis of real-time pressure data of hydraulic support[J]. Coal Engineering,2023,55(3):120-126.

[13] 尹希文,徐刚,刘前进,等. 基于支架载荷的矿压双周期分析预测方法[J]. 煤炭学报,2021,46(10):3116-3126. YIN Xiwen,XU Gang,LIU Qianjin,et al. Method of double-cycle analysis and prediction for rock pressure based on the support load[J]. Journal of China Coal Society,2021,46(10):3116-3126.

[14] 陈毅琪,刘长友,刘锦荣,等. 时空特征统一建模的支架阻力连续性分类及来压特征研究[J]. 采矿与安全工程学报,2024,41(6):1202-1211. CHEN Yiqi,LIU Changyou,LIU Jinrong,et al. Support pressure continuity classification and mine pressure characteristics by unifying spatiotemporal characteristics modeling[J]. Journal of Mining & Safety Engineering,2024,41(6):1202-1211.

[15] 杨柯,熊祖强,王春,等. 综采工作面液压支架阻力精准采集及分析技术研究[J]. 中国煤炭,2024,50(12):131-139. YANG Ke,XIONG Zuqiang,WANG Chun,et al. Research on precise acquisition and analysis technology of hydraulic support resistance in fully mechanized mining face[J]. China Coal,2024,50(12):131-139.

[16] 中煤科工开采研究院有限公司,阳泉煤业(集团)有限责任公司. 工作面液压支架初撑力与循环末阻力的判识方法和系统:202011056466.5[P]. 2020-09-30. CCTEG Coal Mining Research Institute,Yangquan Coal (Group) Co. ,Ltd. Method and system for identifying the initial support force and the resistance at the end of the cycle of the hydraulic support of the working face:202011056466.5[P]. 2020-09-30.

[17] CORTES C,VAPNIK V. Support-vector networks[J]. Machine Learning,1995,20(3):273-297.

[18] LI Haodong. An overview on remote sensing image classification methods with a focus on support vector machine[C]. International Conference on Signal Processing and Machine Learning,Stanford,2021:50-56.

[19] 潘黎明. 基于综合分析法的大采高综放采场来压特征研究[J]. 煤炭科学技术,2015,43(8):60-66. PAN Liming. Study on roof weighting features of high cutting height fully-mechanized top coal caving mining face based on comprehensive analysis method[J]. Coal Science and Technology,2015,43(8):60-66.

[20] 路建军,周宏范,冯明,等. 综采工作面来压步距预测及修正方法研究[J]. 煤炭工程,2022,54(11):118-123. LU Jianjun,ZHOU Hongfan,FENG Ming,et al. Prediction and correction method of weighting interval for fully mechanized mining face[J]. Coal Engineering,2022,54(11):118-123.

[21] 王巍,王文,张广杰. 神东矿区浅埋大采高工作面支架−围岩耦合关系及支架适用性研究[J]. 河南理工大学学报(自然科学版),2025,44(2):32-41. WANG Wei,WANG Wen,ZHANG Guangjie. Study on the coupling relationship between support and surrounding rock and the applicability of support in shallow buried high mining faces of the Shendong Mining Area[J]. Journal of Henan Polytechnic University (Natural Science),2025,44(2):32-41.

-

期刊类型引用(6)

1. 杨瑞,鲍久圣,鲍周洋,阴妍,张磊,潘国宇,杨姣,葛世荣. 煤矿主运大巷轮式巡检机器人摇臂式行走机构设计与试验研究. 工矿自动化. 2025(01): 126-137 .  本站查看

本站查看

2. 张旭飞,王运森,孟祥凯,王瑜,周红,李元辉. 金属矿山井下采场六足机器人运动分析及步态规划. 金属矿山. 2024(04): 193-201 .  百度学术

百度学术

3. 郭文兵,吴东涛,白二虎,张璞,侯建军,张要展. 我国煤矿智能绿色开采技术现状与展望. 河南理工大学学报(自然科学版). 2023(05): 1-17 .  百度学术

百度学术

4. 张丽娟,李学刚,冯立艳,张英. 多直线导向机构轨迹综合的代数求解. 机械设计与研究. 2021(04): 57-61+74 .  百度学术

百度学术

5. 王国法,刘峰,庞义辉,任怀伟,马英. 煤矿智能化——煤炭工业高质量发展的核心技术支撑. 煤炭学报. 2019(02): 349-357 .  百度学术

百度学术

6. 卢万杰,付华,赵洪瑞. 基于深度学习算法的矿用巡检机器人设备识别. 工程设计学报. 2019(05): 527-533 .  百度学术

百度学术

其他类型引用(6)

下载:

下载: