Review on idler fault diagnosis and coordinated control in belt conveyors

-

摘要:

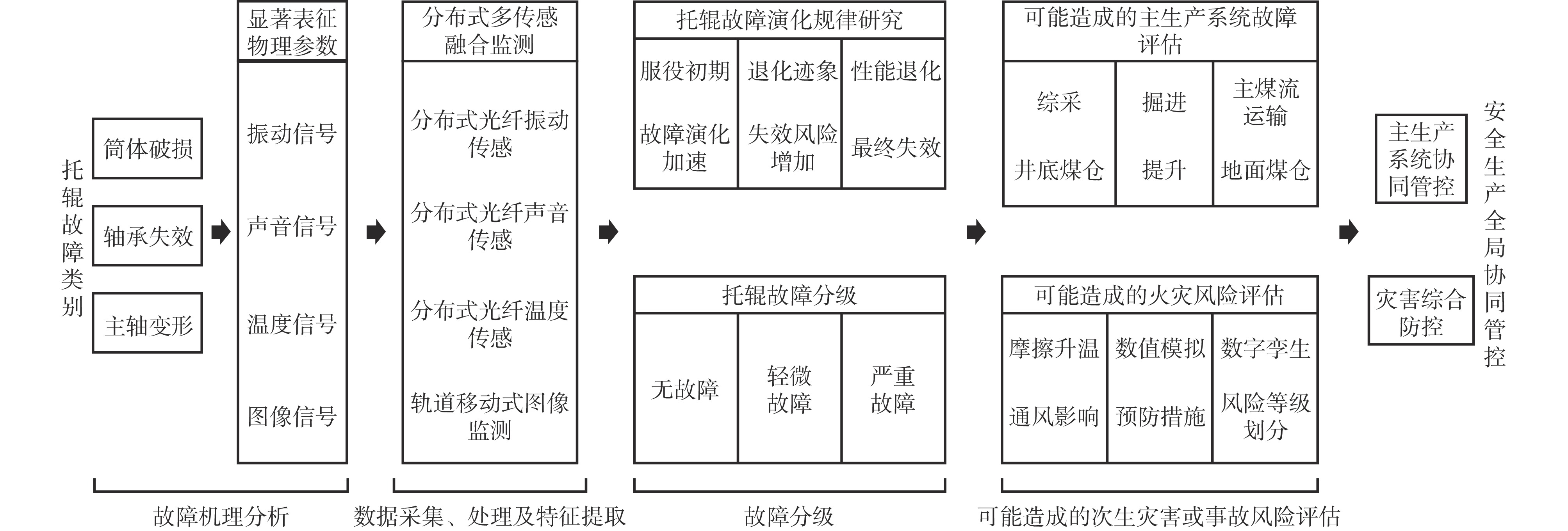

托辊作为带式输送机的关键部件,其故障频发严重影响煤矿生产效率与安全。目前国内外在托辊故障诊断技术和带式输送机管理控制策略方面开展了广泛研究,然而尚未形成一套被广泛认可且行之有效的监测与管控手段。通过分析托辊故障的类型及机理,指出井下带式输送机托辊故障诊断的特殊性及面临的挑战。梳理了托辊故障诊断技术及托辊故障后协同管控的研究现状:在故障状态感知技术方面,探讨了振动、声音、温度及图像信号感知技术的原理与应用;在数据处理及特征提取方面,探讨了各类信号的处理方法及特征提取策略;在故障识别方法方面,探讨了从传统方法到机器学习、深度学习及多源信息融合的托辊故障识别方法的技术演进过程;在托辊故障后协同管控方面,探讨了目前面临控制系统复杂性高、不同控制策略之间的兼容性差、状态监测数据的准确性和实时性难以保证等问题。基于上述研究,指出托辊故障诊断技术虽取得一定进展,但仍存在故障辨识度不高、覆盖范围有限、检测物理量单一、无法对故障进行分类及判断程度、未能评估故障可能引发的风险,以及缺乏全面的管控策略等问题,提出托辊故障诊断技术发展方向:从单一监测向多维度融合监测发展、从稀疏覆盖向密集全面覆盖迈进、从表象诊断向本质分析探究故障演化规律、从被动应对到主动预防的转变并推动从局部管控向全局协同管控的升级。

Abstract:As a critical component of belt conveyors, idlers are prone to frequent failures, significantly impacting the efficiency and safety of coal mine operations. Extensive research has been conducted worldwide on idler fault diagnosis techniques and coordinated control strategies for belt conveyors. However, a universally accepted and effective monitoring and control framework is still lacking. This paper provides a comprehensive review of idler fault types and failure mechanisms, emphasizing the unique challenges associated with diagnosing faults in underground belt conveyors. The current state of research on idler fault diagnosis and post-failure coordinated control is systematically analyzed in four key areas: ① Fault State Perception Technologies: The principles and applications of vibration, acoustic, thermal, and image-based sensing technologies are discussed. ② Data Processing and Feature Extraction: Various signal processing methods and feature extraction strategies are examined. ③ Fault Identification Methods: The evolution of idler fault identification techniques is reviewed, ranging from traditional approaches to advanced machine learning, deep learning, and multi-source information fusion. ④ Post-Failure Coordinated Control: Challenges such as the high complexity of control systems, poor compatibility between different control strategies, and difficulties in ensuring the accuracy and real-time performance of condition monitoring data are highlighted. Despite notable advancements in idler fault diagnosis technologies, several challenges persist, including low fault identification accuracy, limited monitoring coverage, single-parameter detection, and the inability to classify faults or assess their severity. Furthermore, there is inadequate evaluation of potential fault-induced risks and a lack of comprehensive management strategies. Based on these findings, future research directions are proposed: advancing from single-parameter monitoring to multi-dimensional integrated monitoring, transitioning from sparse coverage to dense and comprehensive surveillance, shifting from surface-level diagnosis to in-depth analysis of fault evolution mechanisms, progressing from reactive responses to proactive fault prevention, and promoting the transformation from localized management to global coordinated control.

-

-

表 1 矿用带式输送机托辊故障诱因、现象、显著表征物理量及可能造成的影响

Table 1 Causes, phenomena, significant physical characteristics, and potential impacts of idler faults in mining belt conveyors

诱因 现象 显著表征

物理量故障可能

造成的影响筒体破损 摩擦阻力增大 温度、图像 不停机可能造成胶带损坏,停机可能造成外因火灾 托辊轴承失效 内圈故障 固定频率的微弱冲击 振动、声音 不停机可能造成胶带跑偏 外圈故障 滚珠故障 保持架故障 密封性不足 卡死 温度 筒体或主轴变形 频率不固定的较强烈冲击、卡死 振动、声音、温度、图像 不停机可能造成胶带损伤或胶带跑偏 -

[1] 佟哲. 矿用带式输送机托辊远程故障诊断方法研究[D]. 徐州:中国矿业大学,2020. TONG Zhe. Research on remote fault diagnosis method of idler of mine belt conveyor[D]. Xuzhou:China University of Mining and Technology,2020.

[2] 邱明权. 矿用带式输送机托辊健康监测方法研究[D]. 徐州:中国矿业大学,2018. QIU Mingquan. Study on health monitoring method of idler of mine belt conveyor[D]. Xuzhou:China University of Mining and Technology,2018.

[3] 侯长波. 干涉型光纤振动传感信号解调与识别技术研究[D]. 哈尔滨:哈尔滨工程大学,2021. HOU Changbo. Research on demodulation and identification technology of interferometric optical fiber vibration sensing signal[D]. Harbin:Harbin Engineering University,2021.

[4] 贾振安,赵显锋,高宏,等. 光纤布拉格光栅振动传感器研究[J]. 红外,2020,41(7):18-24. JIA Zhen'an,ZHAO Xianfeng,GAO Hong,et al. Research on fiber bragg grating vibration sensor[J]. Infrared,2020,41(7):18-24.

[5] 张娟,张磊,程文华,等. 一种高灵敏度声表面波振动传感器的设计研究[J]. 仪器仪表学报,2023,44(10):100-111. ZHANG Juan,ZHANG Lei,CHENG Wenhua,et al. Research on the design of a high-sensitivity surface acoustic wave vibration sensor[J]. Chinese Journal of Scientific Instrument,2023,44(10):100-111.

[6] 杜富瑞,陈国良,谷宝平,等. 基于WSN的多金属矿井下人机定位系统设计[J]. 金属矿山,2022(12):165-169. DU Furui,CHEN Guoliang,GU Baoping,et al. Design of personnel and vehicle positioning system in polymetallic mine based on WSN[J]. Metal Mine,2022(12):165-169.

[7] 夏欣. 面向无线振动传感器短时振动信号的分析与诊断[D]. 马鞍山:安徽工业大学,2021. XIA Xin. Analysis and diagnosis of short-term vibration signal for wireless vibration sensor[D]. Maanshan:Anhui University of Technology,2021.

[8] 王森,郭述文,刘秉坤. MEMS光纤振动传感器在大型电机设备异常监测场景的应用研究[J]. 中国设备工程,2024(17):172-174. DOI: 10.3969/j.issn.1671-0711.2024.17.071 WANG Sen,GUO Shuwen,LIU Bingkun. Research on application of MEMS optical fiber vibration sensor in abnormal monitoring scene of large motor equipment[J]. China Plant Engineering,2024(17):172-174. DOI: 10.3969/j.issn.1671-0711.2024.17.071

[9] 井庆贺,张启良,王增仁,等. 带式输送机中间段托辊故障检测方法研究[J]. 中国安全科学学报,2023,33(增刊2):41-48. JING Qinghe,ZHANG Qiliang,WANG Zengren,et al. Research on fault detection method for middle section idler of belt conveyor[J]. China Safety Science Journal,2023,33(S2):41-48.

[10] 郭帅. 带式输送机托辊轴承分布式状态监测系统研制[D]. 淮南:安徽理工大学,2022. GUO Shuai. Development of distributed condition monitoring system for roller bearing of belt conveyor[D]. Huainan:Anhui University of Science & Technology,2022.

[11] 张中盘,张明,时瑛,等. 皮带输送机托辊故障声源定位方法[J]. 噪声与振动控制,2024,44(1):142-147. ZHANG Zhongpan,ZHANG Ming,SHI Ying,et al. Sound source localization method for belt conveyor idler faults[J]. Noise and Vibration Control,2024,44(1):142-147.

[12] 武国平. 带式输送机托辊故障检测方法[J]. 工矿自动化,2023,49(2):149-156. WU Guoping. Fault detection method for belt conveyor idler[J]. Journal of Mine Automation,2023,49(2):149-156.

[13] 伍鹏. 基于麦克风阵列的带式输送机机组智能预警技术研究[D]. 北京:北京化工大学,2023. WU Peng. Research on intelligent early warning technology of belt conveyor unit based on microphone array[D]. Beijing:Beijing University of Chemical Technology,2023.

[14] 吴文臻,程继明,李标. 矿用带式输送机托辊音频故障诊断方法[J]. 工矿自动化,2022,48(9):25-32. WU Wenzhen,CHENG Jiming,LI Biao. Audio fault diagnosis method of mine belt conveyor roller[J]. Journal of Mine Automation,2022,48(9):25-32.

[15] 赵初峰. 基于音频分析技术的矿井带式输送机托辊故障诊断系统研究[J]. 煤炭技术,2023,42(2):200-202. ZHAO Chufeng. Research on fault diagnosis system of supporting roller of mine belt conveyor based on audio analysis technology[J]. Coal Technology,2023,42(2):200-202.

[16] 赵新哲,杨金刚,任磊. 带式输送机托辊故障检测方法研究[J]. 山东煤炭科技,2023,41(4):135-137. ZHAO Xinzhe,YANG Jingang,REN Lei. Research on fault detection method of belt conveyor support roller[J]. Shandong Coal Science and Technology,2023,41(4):135-137.

[17] 朱振. 带式输送机托辊运行状态在线巡检机器人关键技术研究[D]. 阜新:辽宁工程技术大学,2020. ZHU Zhen. Research on key technologies of on-line inspection robot for running status of belt conveyor roller[D]. Fuxin:Liaoning Technical University,2020.

[18] 孙亮. 基于自供能无线传感器网络的托辊监测系统研究[D]. 徐州:中国矿业大学,2022. SUN Liang. Research on roller monitoring system based on self-powered wireless sensor network[D]. Xuzhou:China University of Mining and Technology,2022.

[19] 宋克. TBM连续皮带机托辊巡检机器人系统设计与实现[D]. 石家庄:石家庄铁道大学,2023. SONG Ke. Design and implementation of inspection robot system for roller of TBM continuous belt conveyor[D]. Shijiazhuang:Shijiazhuang Tiedao University,2023.

[20] 胡长斌. 基于视频数据的托辊异常检测研究[D]. 西安:西安科技大学,2021. HU Changbin. Research on roller anomaly detection based on video data[D]. Xi'an:Xi'an University of Science and Technology,2021.

[21] 吉日格勒,柳尧,尚书宏. 带式输送机托辊故障算法研究[J]. 中国安全科学学报,2023,33(增刊2):195-201. JIRI Gele,LIU Yao,SHANG Shuhong. Research on fault detection algorithm of rollers of coal conveyer belts[J]. China Safety Science Journal,2023,33(S2):195-201.

[22] 戴忠林. 带式输送机托辊轴承故障智能诊断与寿命预测研究[D]. 阜新:辽宁工程技术大学,2022. DAI Zhonglin. Research on intelligent diagnosis and life prediction of roller bearing fault of belt conveyor[D]. Fuxin:Liaoning Technical University,2022.

[23] 李涛. 带式输送机运行状态智能监控系统研究[D]. 西安:西安建筑科技大学,2020. LI Tao. Research on intelligent monitoring system of belt conveyor running state[D]. Xi'an:Xi'an University of Architecture and Technology,2020.

[24] 周毅炜. 光纤分布式传感系统在胶带机故障信号检测中的应用研究[D]. 成都:电子科技大学,2023. ZHOU Yiwei. Research on application of optical fiber distributed sensing system in fault signal detection of belt conveyor[D]. Chengdu:University of Electronic Science and Technology of China,2023.

[25] 彭程程. 基于二阶瞬态提取变换的滚动轴承故障特征提取方法研究[J]. 机电工程,2021,38(10):1246-1252. PENG Chengcheng. Fault feature extraction method for rolling bearing based on STET[J]. Journal of Mechanical & Electrical Engineering,2021,38(10):1246-1252.

[26] 李勇. 基于数据驱动的带式输送机轴承故障诊断技术研究[D]. 徐州:中国矿业大学,2021. LI Yong. Research on fault diagnosis technology of belt conveyor bearing based on data driving[D]. Xuzhou:China University of Mining and Technology,2021.

[27] 仪继超. 基于分布式光纤传感系统的带式传输机故障监测技术研究[D]. 济南:齐鲁工业大学,2023. YI Jichao. Research on fault monitoring technology of belt conveyor based on distributed optical fiber sensing system[D]. Jinan:Qilu University of Technology,2023.

[28] 曹贯强. 带式输送机托辊故障检测方法[J]. 工矿自动化,2020,46(6):81-86. CAO Guanqiang. Fault detection method for belt conveyor roller[J]. Industry and Mine Automation,2020,46(6):81-86.

[29] 贺志军,李军霞,刘少伟,等. CEEMD−VMD与参数优化SVM结合的托辊轴承故障诊断[J]. 机械科学与技术,2024,43(3):402-408. HE Zhijun,LI Junxia,LIU Shaowei,et al. Roller bearing fault diagnosis combined CEEMD-VMD and parameter optimization SVM[J]. Mechanical Science and Technology for Aerospace Engineering,2024,43(3):402-408.

[30] 邱园园. 多种时频图联合的托辊故障诊断方法研究[D]. 银川:宁夏大学,2022. QIU Yuanyuan. Research on fault diagnosis method of idler combined with multiple time-frequency graphs[D]. Yinchuan:Ningxia University,2022.

[31] 李羽蒙,樊红. 基于MFCC特征与卷积神经网络的托辊故障诊断方法[J]. 武汉大学学报(工学版),2024,57(5):691-698. LI Yumeng,FAN Hong. A fault diagnosis method of roller based on MFCC features and convolutional neural network[J]. Engineering Journal of Wuhan University,2024,57(5):691-698.

[32] 郭洁,井庆贺,闫寿庆,等,基于MFCC声音特征信号提取的托辊故障诊断[J]. 中国安全科学学报,2023,33(增刊2):116-121. GUO Jie,JING Qinghe,YAN Shouqing,et al. Roller fault diagnosis based on MFCC sound feature signal extraction[J]. China Safety Science Journal,2023,33(S2):116-121.

[33] 伊鑫,杨明锦,杨林顺,等. 基于KNN与SVM两级综合健康指标的托辊故障诊断方法[J]. 选煤技术,2020,48(5):94-102. YI Xin,YANG Mingjin,YANG Linshun,et al. The KNN and SVM-based 2-level comprehensive health indicators diagnosis method for detecting the failure of belt conveyor’s idlers[J]. Coal Preparation Technology,2020,48(5):94-102.

[34] 陶瀚宇,陈换过,彭程程,等. 基于MFCC−IMFCC混合倒谱的托辊轴承故障诊断[J]. 机电工程,2024,41(7):1215-1222. TAO Hanyu,CHEN Huanguo,PENG Chengcheng,et al. Fault diagnosis of idler bearings based on MFCC-IMFCC hybrid cepstral coefficients[J]. Journal of Mechanical & Electrical Engineering,2024,41(7):1215-1222.

[35] 张启虎. 基于PCHIP−EWT声音处理技术的带式输送机故障诊断系统研究[D]. 曲阜:曲阜师范大学,2024. ZHANG Qihu. Research on fault diagnosis system of belt conveyor based on PCHIP-EWT sound processing technology[D]. Qufu:Qufu Normal University,2024.

[36] 刘春,张明,董帆,等. 基于包络谱峭度的输送皮带托辊故障特征提取[J]. 机电信息,2023(7):59-63. LIU Chun,ZHANG Ming,DONG Fan,et al. Extraction of fault characteristics of conveyor belt roller based on envelope spectrum[J]. Mechanical and Electrical Information,2023(7):59-63.

[37] 贺志军. 基于机器学习算法的带式输送机托辊故障诊断方法研究[D]. 太原:太原理工大学,2023. HE Zhijun. Research on fault diagnosis method of belt conveyor idler based on machine learning algorithm[D]. Taiyuan:Taiyuan University of Technology,2023.

[38] 缪江华. 基于卷积神经网络的带式输送机托辊故障诊断[J]. 煤矿机械,2024,45(6):182-185. MIAO Jianghua. Fault diagnosis of belt conveyor roller based on convolutional neural network[J]. Coal Mine Machinery,2024,45(6):182-185.

[39] 韩信. 基于声信号的托辊轴承故障诊断方法研究[D]. 淮南:安徽理工大学,2024. HAN Xin. Research on fault diagnosis method of idler bearing based on acoustic signal[D]. Huainan:Anhui University of Science & Technology,2024.

[40] 刘玉良. 光纤测温中温度解调与去噪方法的研究[D]. 淮南:安徽理工大学,2010. LIU Yuliang. Research on temperature demodulation and denoising method in optical fiber temperature measurement[D]. Huainan:Anhui University of Science & Technology,2010.

[41] 宁武霆,赵春菊,周宜红,等. 混凝土坝光纤测温噪声特征及降噪方法[J]. 水电能源科学,2021,39(6):73-76,80. NING Wuting,ZHAO Chunju,ZHOU Yihong,et al. Combined noise reduction model of distributed optical fiber temperature measurement data for concrete dam[J]. Water Resources and Power,2021,39(6):73-76,80.

[42] 丁厚轩. 带式输送机关键部位异常温度监测系统研究[D]. 徐州:中国矿业大学,2023. DING Houxuan. Research on abnormal temperature monitoring system of key parts of belt conveyor[D]. Xuzhou:China University of Mining and Technology,2023.

[43] 郭清华. 基于光纤测温技术的带式输送机托辊故障识别算法研究[J]. 煤矿机械,2018,39(8):157-160. GUO Qinghua. Research on roller fault identification algorithm of belt conveyor system based on fiber temperature measurement technology[J]. Coal Mine Machinery,2018,39(8):157-160.

[44] 郭清华. 基于光纤测温的托辊轴温检测及热传导模型研究[J]. 矿业安全与环保,2020,47(1):66-69,74. GUO Qinghua. Research on roller shaft temperature detection and thermal conductivity model based on optical fiber temperature measurement[J]. Mining Safety & Environmental Protection,2020,47(1):66-69,74.

[45] 王金凤. 基于多信息融合的带式输送机故障诊断研究[D]. 曲阜:曲阜师范大学,2021. WANG Jinfeng. Research on fault diagnosis of belt conveyor based on multi-information fusion[D]. Qufu:Qufu Normal University,2021.

[46] 张俊. 基于红外热成像技术的托辊故障诊断系统研究[J]. 机械研究与应用,2023,36(4):174-178. ZHANG Jun. Research on idler fault diagnosis system based on infrared thermal imaging technology[J]. Mechanical Research & Application,2023,36(4):174-178.

[47] 马宏伟,杨文娟,张旭辉. 基于红外热像的带式输送机监测与预警系统[J]. 激光与红外,2017,47(4):448-452. MA Hongwei,YANG Wenjuan,ZHANG Xuhui. Monitoring and warning system of belt conveyor based on infrared thermography[J]. Laser & Infrared,2017,47(4):448-452.

[48] 井坤. 基于红外图像处理的带式输送机故障诊断系统研究[D]. 曲阜:曲阜师范大学,2021. JING Kun. Research on fault diagnosis system of belt conveyor based on infrared image processing[D]. Qufu:Qufu Normal University,2021.

[49] 金学智. 基于红外图像的带式输送机故障预警方法研究[D]. 银川:宁夏大学,2021. JIN Xuezhi. Research on fault early warning method of belt conveyor based on infrared image[D]. Yinchuan:Ningxia University,2021.

[50] 阮顺领,阮炎康,卢才武,等. 基于红外图像的矿石传送带托辊异常检测[J]. 黄金科学技术,2023,31(1):123-132. RUAN Shunling,RUAN Yankang,LU Caiwu,et al. Detection of ore conveyer roller based on infrared image[J]. Gold Science and Technology,2023,31(1):123-132.

[51] 郭盈辉. 基于机器视觉的带式输送机托辊故障检测的研究[D]. 天津:天津工业大学,2022. GUO Yinghui. Research on fault detection of belt conveyor idler based on machine vision[D]. Tianjin:Tianjin Polytechnic University,2022.

[52] 陈岩. 带式输送机传动滚筒轴承故障智能诊断[J]. 工矿自动化,2023,49(增刊1):56-59,137. CHEN Yan. Intelligent fault diagnosis of belt conveyor drive roller bearing[J]. Journal of Mine Automation,2023,49(S1):56-59,137.

[53] 谢苗,孟庆爽,马苏宁,等. 分布式光纤传感系统托辊故障监测技术研究[J/OL]. 机械科学与技术:1-11[2024-12-06]. https://doi.org/10.13433/j.cnki.1003-8728.20240092. XIE Miao,MENG Qingshuang,MA Suning,et al. Research on fault monitoring technology for roller in distributed fiber optic sensing system[J/OL]. Mechanical Science and Technology for Aerospace Engineering :1-11[2024-12-06]. https://doi.org/10.13433/j.cnki.1003-8728.20240092.

[54] 缪江华,苑静科,王文硕. 基于堆叠稀疏自编码和谱聚类分析的带式输送机托辊故障诊断[J]. 煤矿机械,2024,45(7):163-166. MIAO Jianghua,YUAN Jingke,WANG Wenshuo. Fault diagnosis of belt conveyor roller based on stacked sparse autoencoder and spectral clustering analysis[J]. Coal Mine Machinery,2024,45(7):163-166.

[55] 梁堃,王驰. 基于分布式光纤声波传感器的带式输送机托辊故障监测方法[J]. 激光与光电子学进展,2023,60(9):276-284. LIANG Kun,WANG Chi. Roller fault monitoring of belt conveyor using distributed fiber-optic acoustic sensor[J]. Laser & Optoelectronics Progress,2023,60(9):276-284.

[56] 刘勇. 基于声信号的带式输送机托辊故障特征分析[J]. 中国安全科学学报,2023,33(增刊2):13-17. LIU Yong. Fault characteristic analysis of belt conveyor rollers based on sound signal[J]. China Safety Science Journal,2023,33(S2):13-17.

[57] 董乃吉. 基于声音信号的带式输送机托辊故障预警与定位研究[D]. 北京:北京化工大学,20240. DONG Naiji. Research on fault early warning and location of belt conveyor idler based on sound signal[D]. Beijing:Beijing University of Chemical Technology,2024.

[58] 宋天祥,杨明锦,杨林顺,等. 基于谱聚类分析的托辊故障诊断[J]. 电子测量技术,2019,42(5):144-150. SONG Tianxiang,YANG Mingjin,YANG Linshun,et al. Fault diagnosis for roller based on spectral clustering analysis[J]. Electronic Measurement Technology,2019,42(5):144-150.

[59] 董瑞佳. 基于迁移学习和DenseNet的带式输送机托辊故障检测方法[J]. 煤炭技术,2023,42(1):250-252. DONG Ruijia. Fault detection method of belt conveyor idler based on transfer learning and DenseNet[J]. Coal Technology,2023,42(1):250-252.

[60] 张高祥. 基于声音信号的带式输送机托辊故障检测系统设计与研究[D]. 徐州:中国矿业大学,2022. ZHANG Gaoxiang. Design and research on fault detection system of belt conveyor roller based on sound signal[D]. Xuzhou:China University of Mining and Technology,2022.

[61] 张伟,李军霞,吴磊,等. 基于1DCNN−ELM的带式输送机托辊轴承故障诊断研究[J]. 煤炭科学技术,2023,51(增刊1):383-389. ZHANG Wei,LI Junxia,WU Lei,et al. Research on fault diagnosis of idler bearing of belt conveyor based on 1DCNN-ELM[J]. Coal Science and Technology,2023,51(S1):383-389.

[62] 张雄,武文博,李嘉禄,等. 基于波束形成及CNN−LSTM的托辊故障距离估计模型[J]. 噪声与振动控制,2024,44(5):114-119. ZHANG Xiong,WU Wenbo,LI Jialu,et al. Roller fault distance estimation model based on beamforming and CNN-LSTM[J]. Noise and Vibration Control,2024,44(5):114-119.

[63] 陈维望,李军霞,张伟. 基于分支卷积神经网络的托辊轴承故障分级诊断研究[J]. 机电工程,2022,39(5):596-603. CHEN Weiwang,LI Junxia,ZHANG Wei. Hierarchical fault diagnosis of idler bearing based on branch convolutional neural network[J]. Journal of Mechanical & Electrical Engineering,2022,39(5):596-603.

[64] 张皞正. 基于数据的托辊故障诊断方法的研究[D]. 沈阳:东北大学,2021. ZHANG Haozheng. Data-based research on fault diagnosis method of roller based[D]. Shenyang:Northeastern University,2021.

[65] 白渊铭. 多源异构数据融合的带式输送机深度学习故障检测算法研究[D]. 太原:太原师范学院,2023. BAI Yuanming. Research on fault detection algorithm of belt conveyor based on multi-source heterogeneous data fusion[D]. Taiyuan:Taiyuan Normal University,2023.

[66] 宋鹏飞,梅秀庄,尚志强,等. 基于数字孪生的带式输送机状态综合监测[J]. 煤矿机械,2024,45(1):196-198. SONG Pengfei,MEI Xiuzhuang,SHANG Zhiqiang,et al. Comprehensive monitoring of belt conveyor state based on digital twin[J]. Coal Mine Machinery,2024,45(1):196-198.

[67] 高波,袁媛,岳伟,等. 基于机器学习的托辊故障等级评价模型研究[J]. 物流科技,2023,46(13):32-35. GAO Bo,YUAN Yuan,YUE Wei,et al. Research on fault grade evaluation model of roller based on machine learning[J]. Logistics Sci-Tech,2023,46(13):32-35.

[68] 李士明,马新宇,郭依尉. 煤矿主运输皮带故障智能诊断与保护研究[J]. 中国矿业,2012,21(增刊1):592-595. LI Shiming,MA Xinyu,GUO Yiwei. The research on intelligent diagnosis and protection of the fault of the main transportation belt in coal mine[J]. China Mining Magazine,2012,21(S1):592-595.

[69] 宋超. 掘进巷道带式输送机常见故障及处理措施[J]. 现代机械,2022(1):100-102. SONG Chao. Common faults and countermeasures of belt conveyor in excavation roadway[J]. Modern Machinery,2022(1):100-102.

[70] 郑茂全. 煤矿带式输送机的优化控制与状态监测的研究[D]. 西安:西安科技大学,2015. ZHENG Maoquan. Study on optimal control and condition monitoring of belt conveyor in coal mine[D]. Xi'an:Xi'an University of Science and Technology,2015.

[71] 赵炎. 基于电流检测的带式输送机故障预判和节能研究[D]. 秦皇岛:燕山大学,2015. ZHAO Yan. Research on fault prediction and energy saving of belt conveyor based on current detection[D]. Qinhuangdao:Yanshan University,2015.

[72] 曹帅,王晓鹏,鲍康润. 煤矿胶带输送机常见故障处理技术研究[J]. 现代制造技术与装备,2024,60(9):166-168. CAO Shuai,WANG Xiaopeng,BAO Kangrun. Research on common fault handling technology of coal mine belt conveyor[J]. Modern Manufacturing Technology and Equipment,2024,60(9):166-168.

[73] 罗伟刚. 皮带运输机在煤矿运输中的常见故障与处理[J]. 矿业装备,2023(3):176-178. LUO Weigang. Common faults and treatment of belt conveyor in coal mine transportation[J]. Mining Equipment,2023(3):176-178.

[74] 爱保柱. 煤矿胶带输送机常见故障分析及处理[J]. 矿业装备,2022(2):262-263. AI Baozhu. Analysis and treatment of common faults of coal mine belt conveyor[J]. Mining Equipment,2022(2):262-263.

-

期刊类型引用(14)

1. 谭超,闵薪宇,辛亮,孙其浩,谭继伟,欧星作. 一种基于单轴向充磁永磁环励磁的钢丝绳无损检测方法. 传感技术学报. 2024(04): 731-736 .  百度学术

百度学术

2. 赵陆. 电梯钢丝绳损伤检测装置设计. 机械管理开发. 2024(12): 105-106+109 .  百度学术

百度学术

3. 曹义威,张士超,陈小伟,徐光鹏,何宝林. 海洋石油钻修井钢丝绳在线监测技术研究与应用. 无损探伤. 2023(04): 30-33 .  百度学术

百度学术

4. 王文庆,刘文辉,李生辉,徐午言. 基于永磁环励磁结构的钢丝绳无损检测设计. 西安邮电大学学报. 2023(05): 92-101 .  百度学术

百度学术

5. 田劼,孙钢钢,李睿峰,王伟. 基于正交试验的钢丝绳探伤仪结构参数优化. 工矿自动化. 2022(09): 100-108 .  本站查看

本站查看

6. 王红尧,吴佳奇,李长恒,唐文锦,张艳林. 矿用钢丝绳损伤检测信号处理方法研究. 工矿自动化. 2021(02): 58-62 .  本站查看

本站查看

7. 窦连城,战卫侠,白晓瑞. 钢丝绳内外部断丝损伤识别. 工矿自动化. 2021(03): 83-88 .  本站查看

本站查看

8. 王红尧,田劼,张艳林,刘志宏,陈艺童. 矿用钢丝绳在线监测教学实验装置关键技术. 煤矿安全. 2021(06): 177-182 .  百度学术

百度学术

9. 王锐. 参加者较少的钢丝拉伸能力验证评价方法应用. 机械研究与应用. 2021(03): 208-211 .  百度学术

百度学术

10. 靳志强. 矿用提升机钢丝绳损伤检测装置的设计. 机械管理开发. 2021(08): 253-255 .  百度学术

百度学术

11. 田劼,王洋洋,郭红飞,赵彩跃. 基于漏磁检测的钢丝绳探伤原理与方法研究. 煤炭工程. 2021(09): 95-100 .  百度学术

百度学术

12. 王红尧,李小伟,韩亦淼,吕昕. 矿用钢丝绳损伤检测系统设计. 工矿自动化. 2020(06): 92-97 .  本站查看

本站查看

13. 张方泽. 矿用提升机制动过程与制动效果分析. 低碳世界. 2020(08): 166-167 .  百度学术

百度学术

14. 窦连城,战卫侠. 钢丝绳断丝损伤漏磁场计算与仿真研究. 工矿自动化. 2020(10): 87-91 .  本站查看

本站查看

其他类型引用(12)

下载:

下载: