Summary of fault diagnosis methods for belt conveyor systems

-

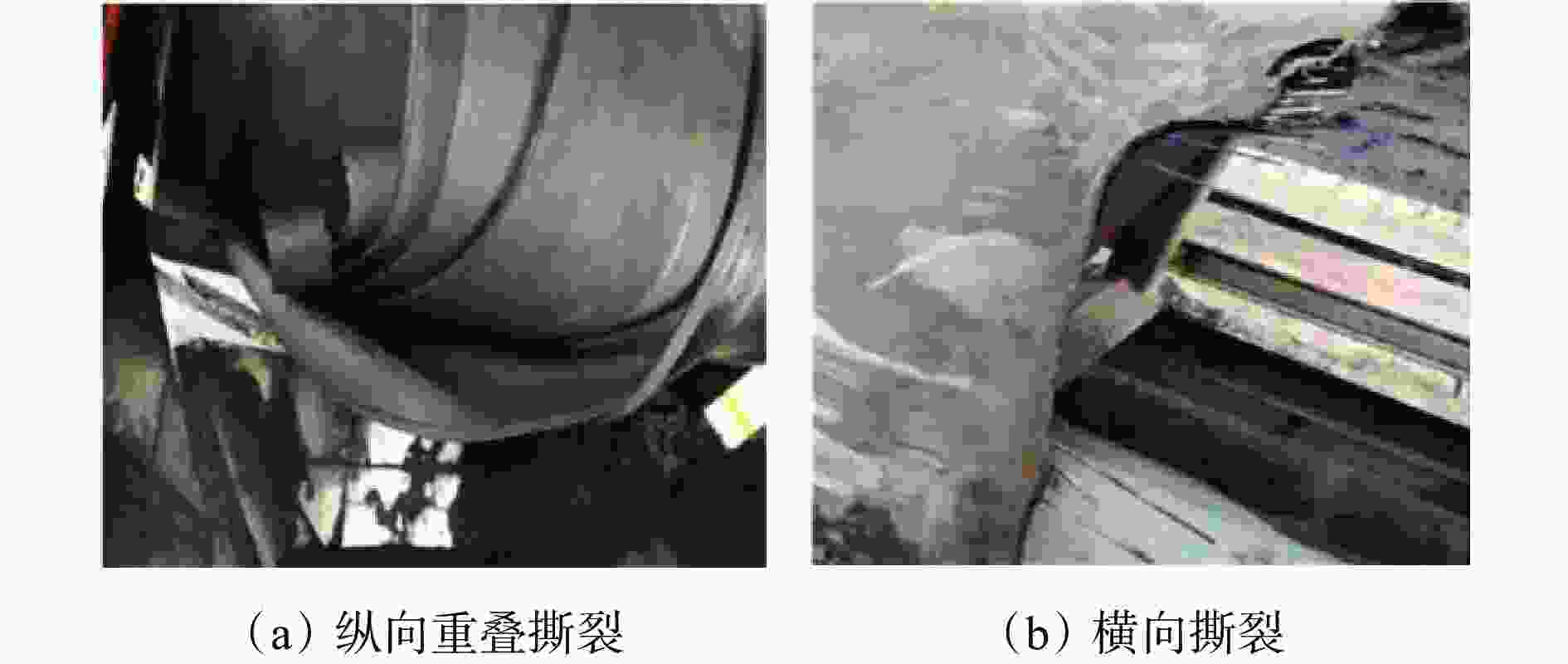

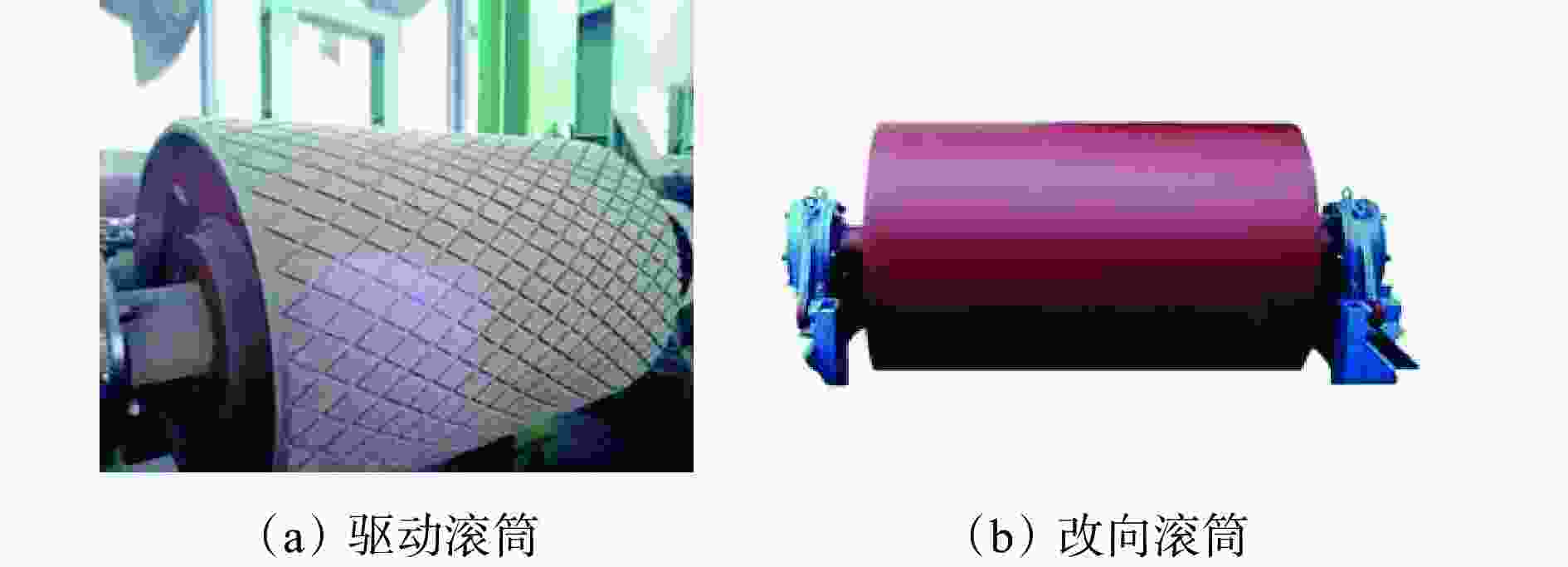

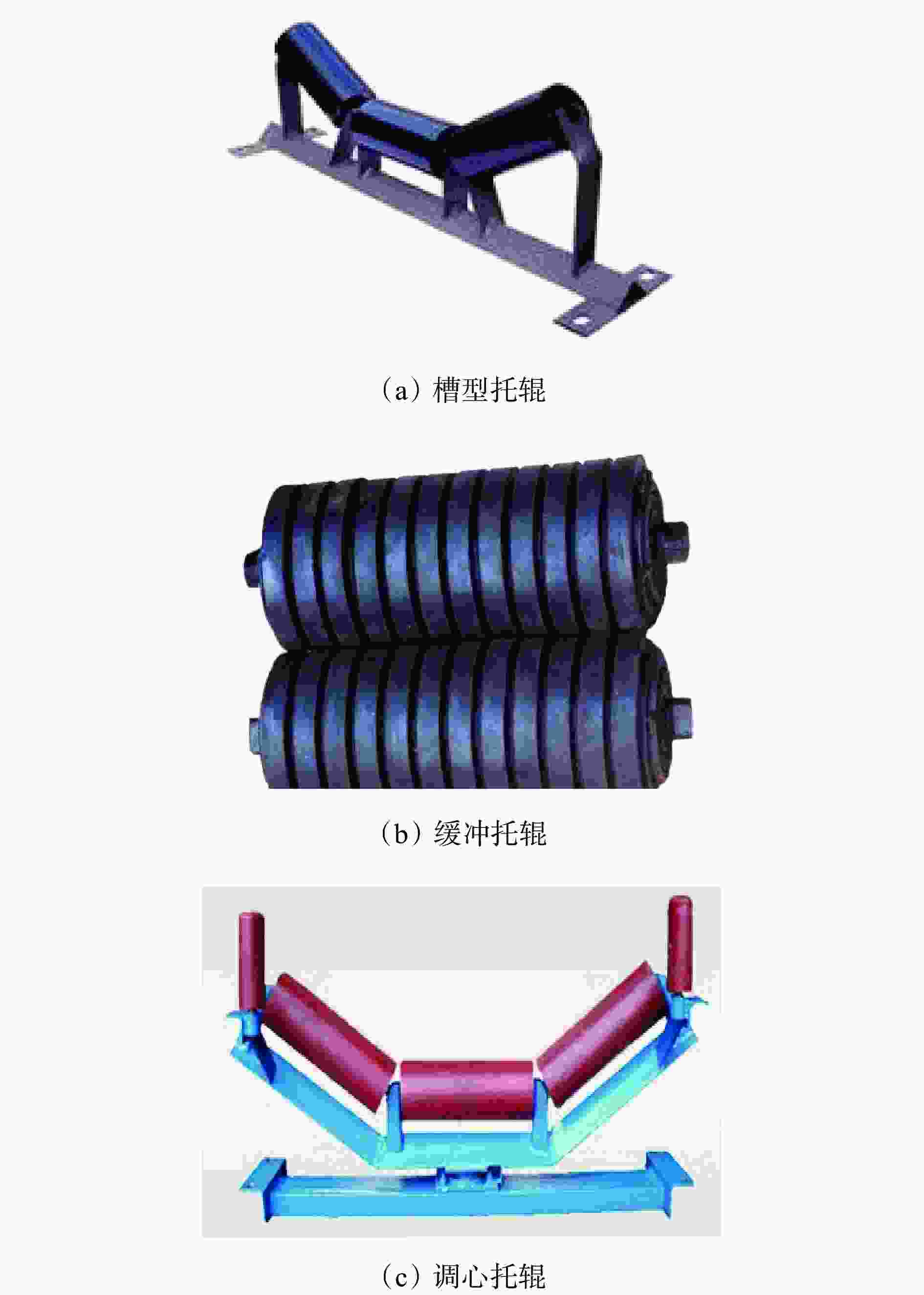

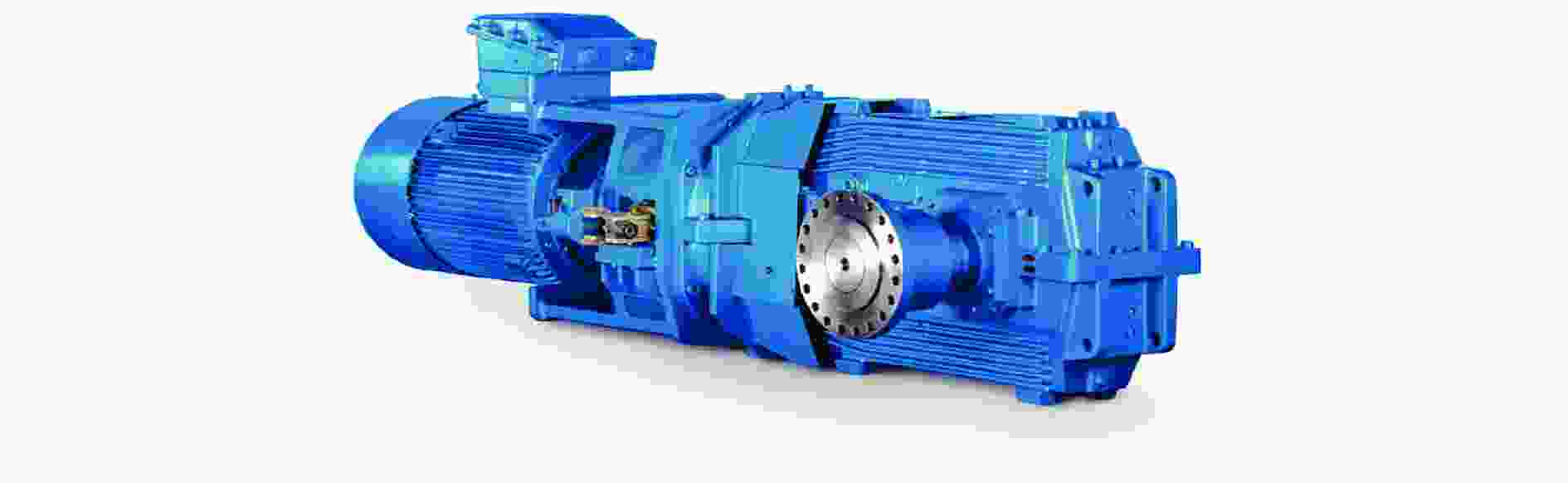

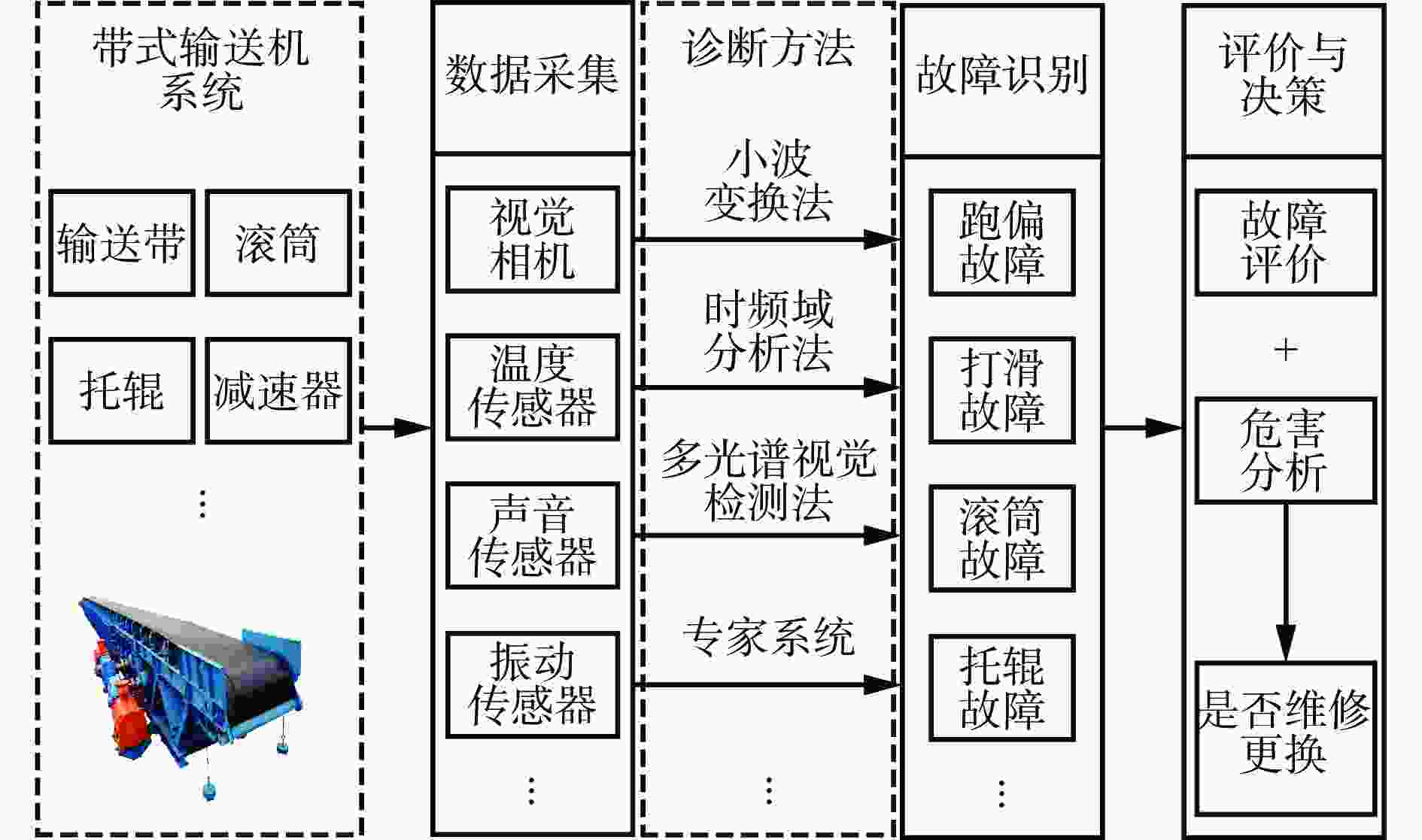

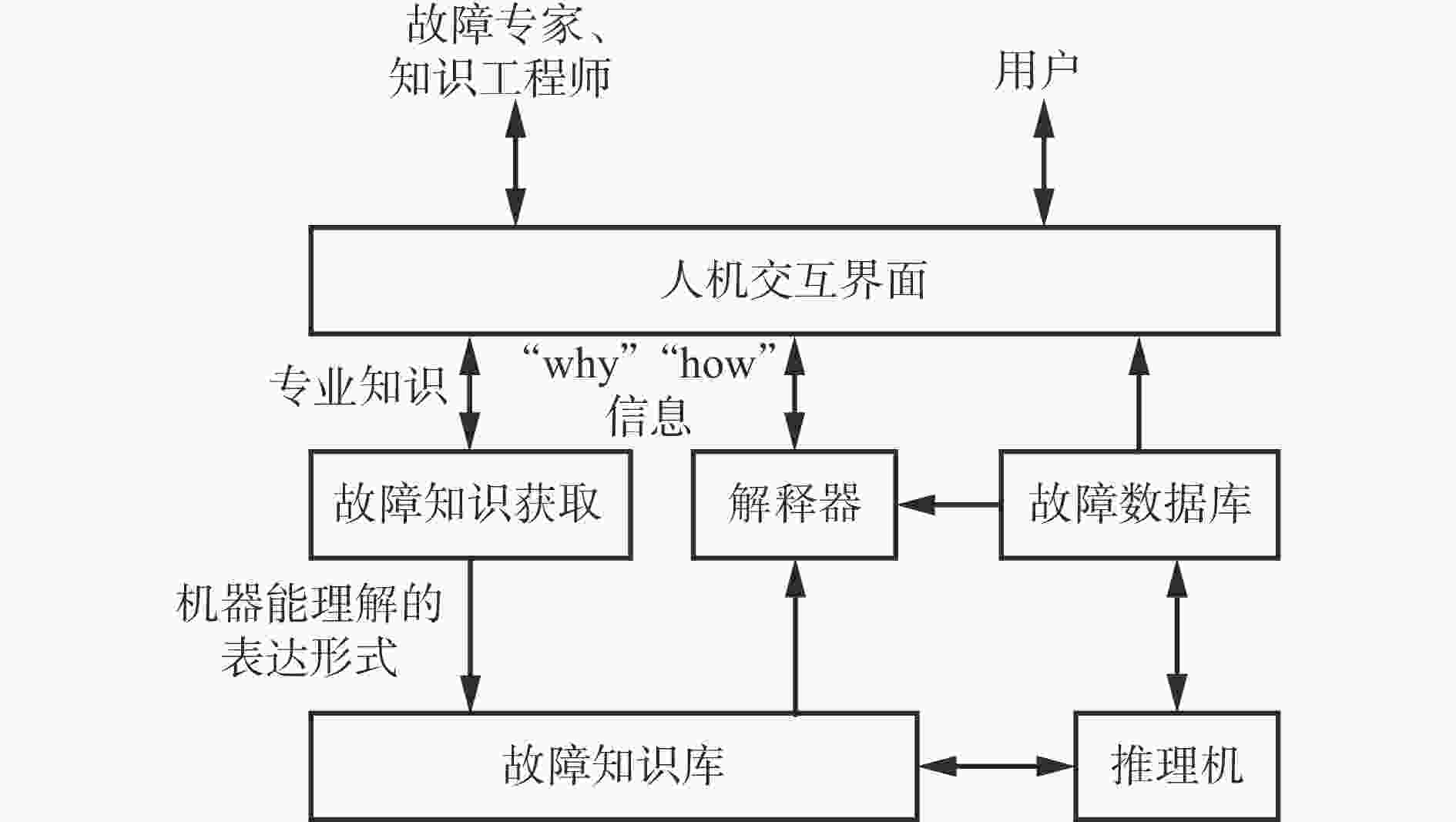

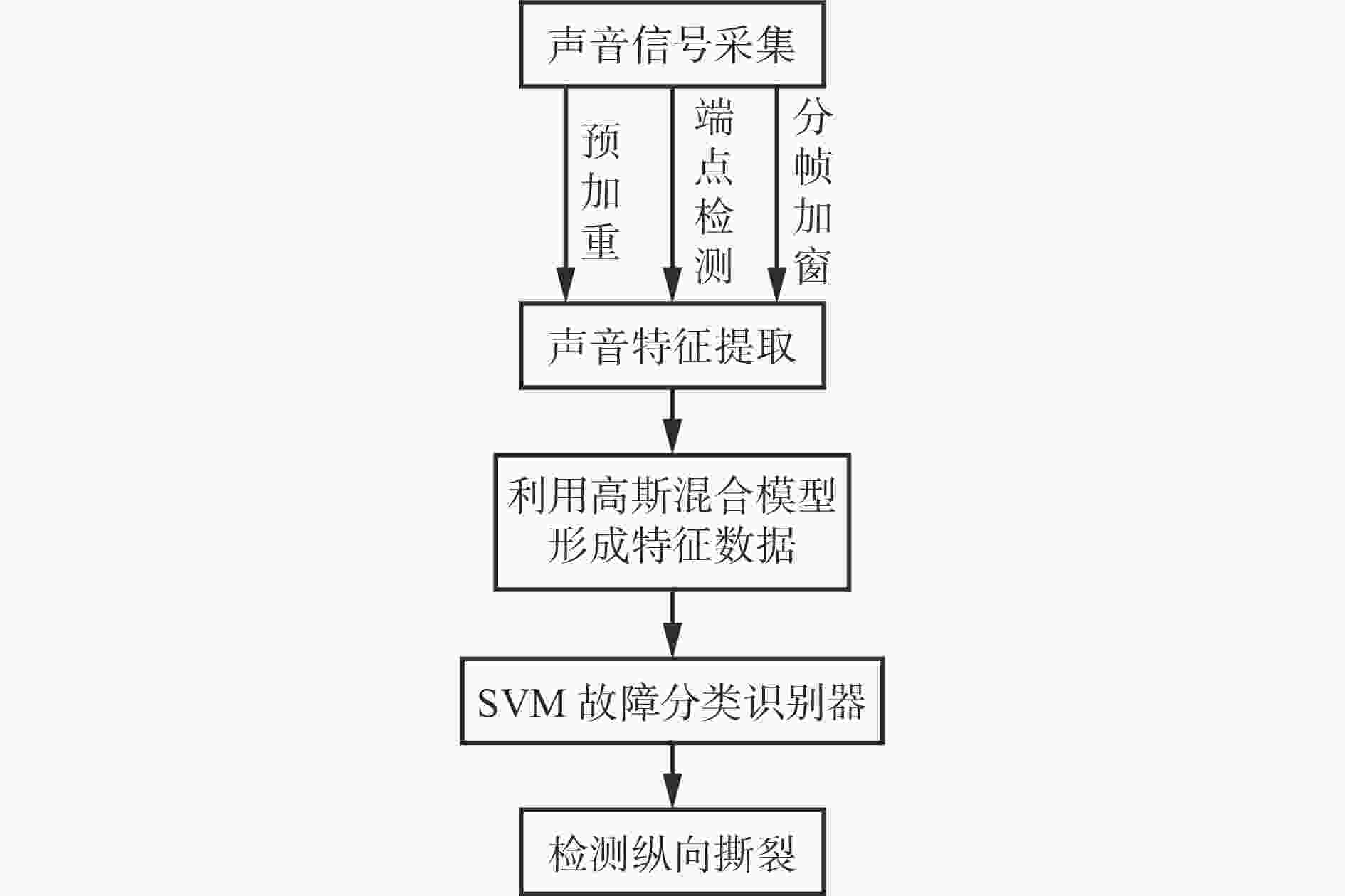

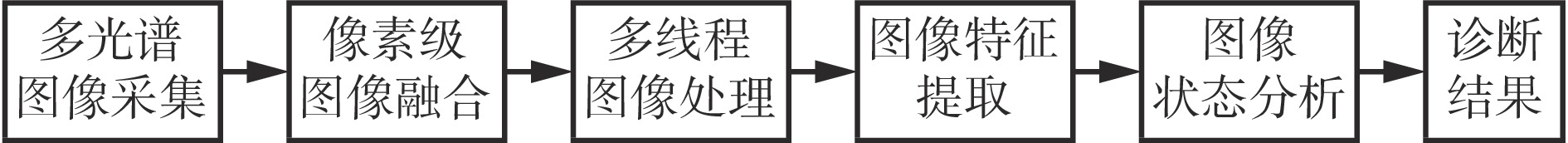

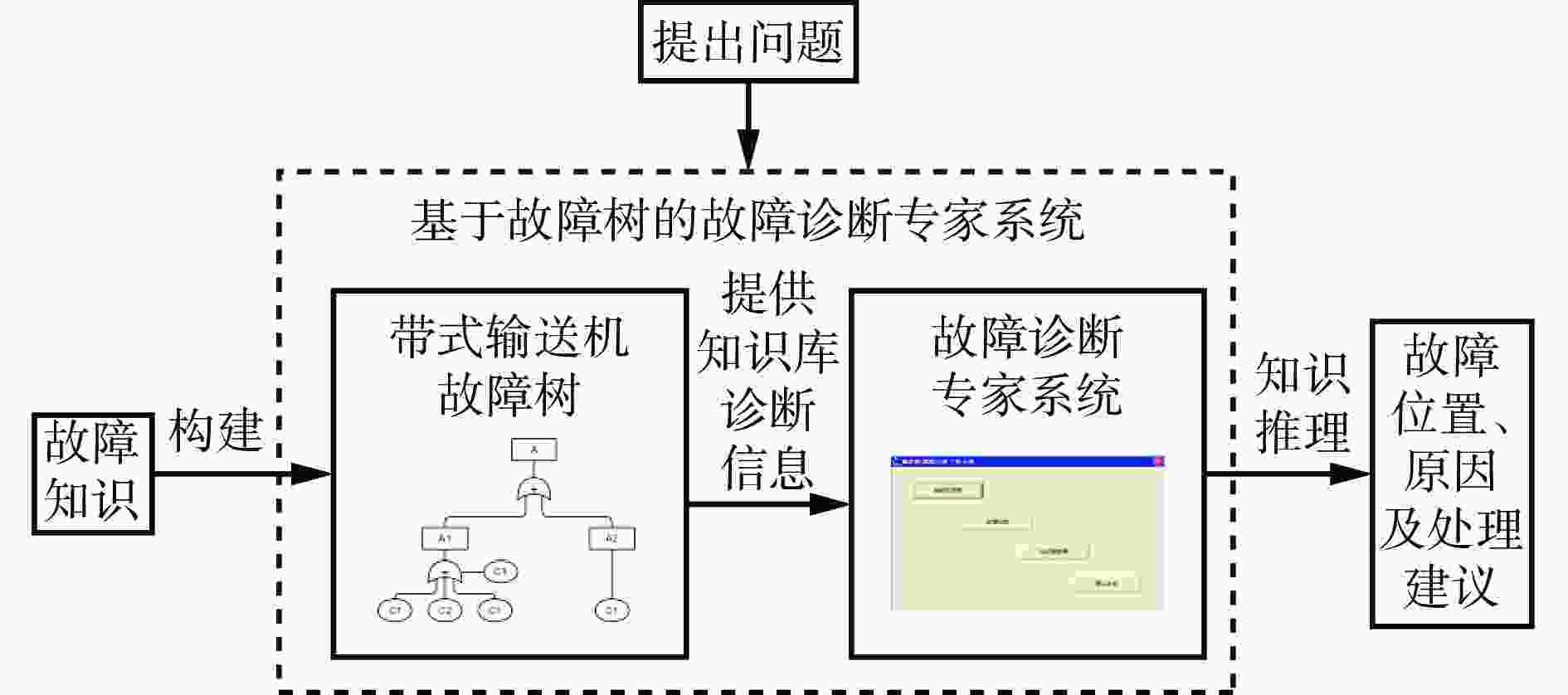

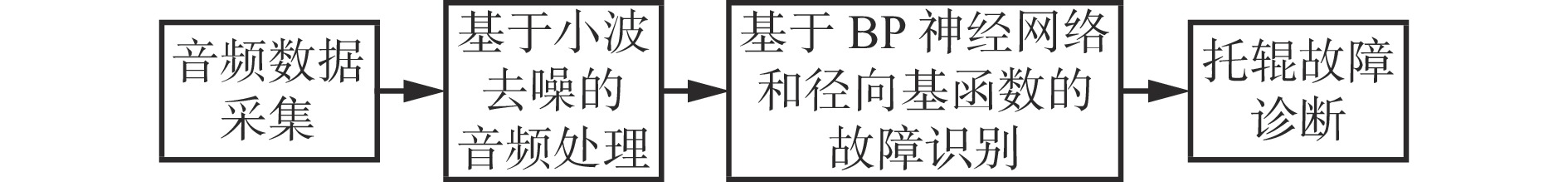

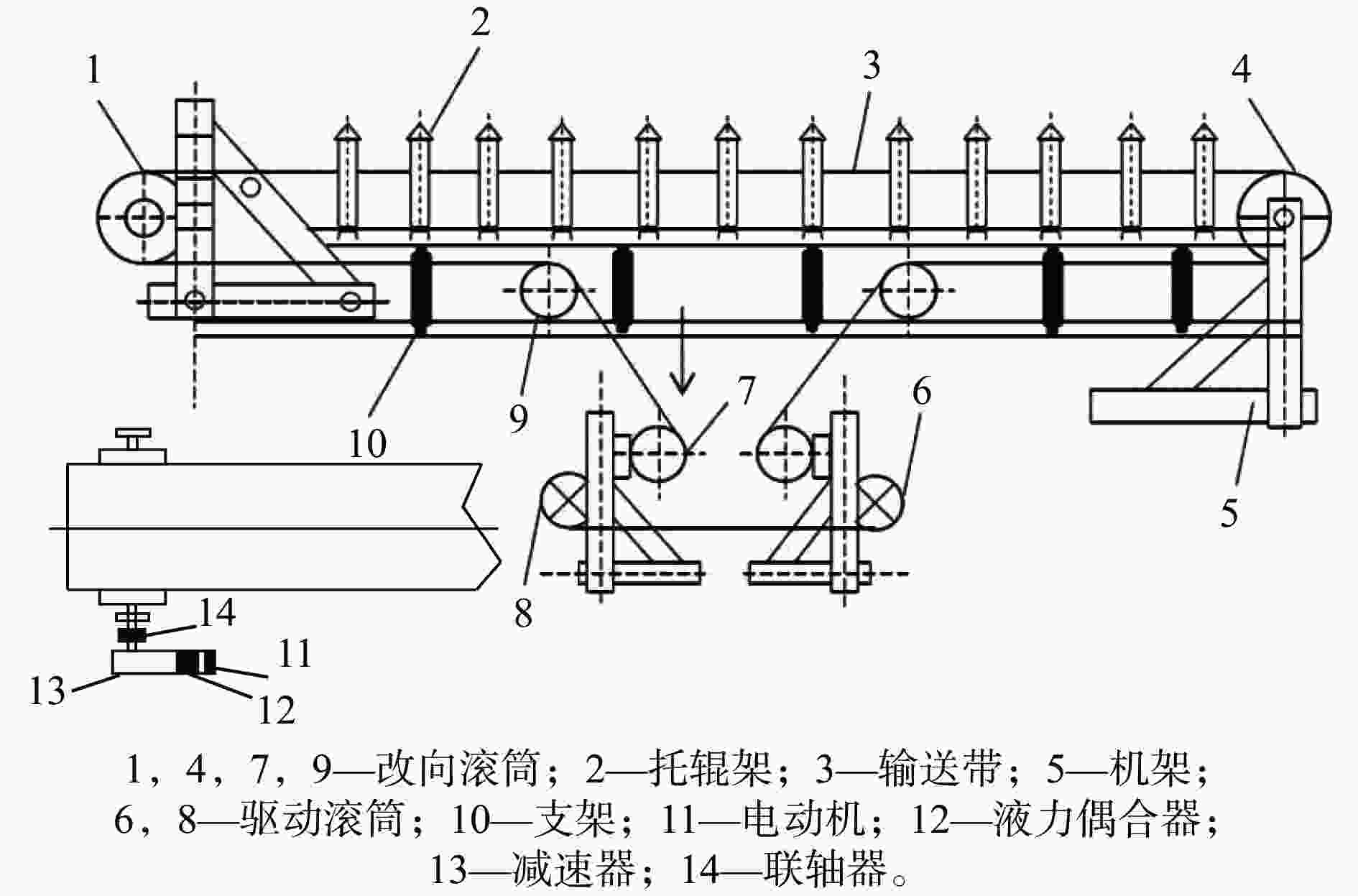

摘要: 输送带和驱动装置是带式输送机的主要组成部分且为故障高发部位,以输送带故障和驱动装置故障为切入点,分析了输送带跑偏、打滑、损伤、堆料撒料等故障及驱动装置滚筒、托辊、减速器等故障的机理,重点阐述了知识驱动和数据驱动的带式输送机故障诊断方法研究进展。知识驱动法以知识处理技术为基础,实现符号处理和数值处理的统一、推理过程和算法过程的统一,主要包括专家系统、故障树分析法。数据驱动法采用机器学习和数据挖掘等技术对历史数据进行分析处理,建立诊断模型,达到故障诊断目的,主要包括支持向量机(SVM)、比差法、基于声音和视觉的诊断方法。分析了带式输送机故障诊断方法目前存在的挑战和未来发展趋势:① 结合历史故障数据和实时数据推断设备健康状况,预测早期微小故障,提醒工作人员进行预测性维护。② 揭示带式输送机耦合故障的关联关系,利用人工智能等新兴技术研究耦合故障联合诊断方法。③ 利用多模态机器学习技术研究带式输送机多模态信息融合利用机制,开发带式输送机多模态信息融合故障诊断方法。④ 将故障知识图谱和带式输送机领域知识相结合,实现带式输送机设备故障追踪、故障超前预警,通过知识查询、知识推理和辅助决策功能,提高故障处理、精准挖掘设备潜在故障风险的能力。Abstract: The conveyor belt and driving device are the main components of the belt conveyor and are the high-risk areas for faults. Taking conveyor belt faults and driving device faults as the starting point, this paper analyzes the mechanisms of conveyor belt deviation, slipping, damage, stacking and scattering, as well as the faults of the driving device roller, idler and reducer. It focuses on the research progress of knowledge-driven and data-driven fault diagnosis methods for belt conveyors. Based on the knowledge processing technology, the knowledge-driven method realizes the unification of symbol processing and numerical processing, the unification of reasoning process and algorithm process. It mainly includes expert system and fault tree analysis. The data-driven method uses machine learning and data mining techniques to analyze and process historical data. It establishes diagnostic models, and achieves fault diagnosis purposes. It mainly includes support vector machines (SVM), comparison method, and diagnosis methods based on sound and vision. This paper analyzes the current challenges and future development trend of belt conveyor fault diagnosis methods. ① The historical fault data and real-time data should be combined to infer equipment health. The early minor faults should be predicted so as to remind the staff to carry out predictive maintenance. ② The correlation between coupling faults of belt conveyors should be revealed. The emerging technologies such as artificial intelligence should be used to study joint diagnosis methods for coupling faults. ③ The multimodal machine learning technology should be utilized to study the mechanism of multimodal information fusion and utilization of belt conveyors. Fault diagnosis methods for multimodal information fusion of belt conveyors needs to develop. ④ The fault knowledge graph and the belt conveyor domain knowledge should be combined to realize the belt conveyor equipment fault tracking and fault early warning. Through the knowledge query, knowledge reasoning and auxiliary decision-making functions, the capability of fault handling and precise mining of potential fault risks of equipment can be improved.

-

Key words:

- belt conveyor /

- fault diagnosis /

- conveyor belt fault /

- driving device fault /

- knowledge-driven /

- data-driven

-

表 1 各类故障诊断方法对比

Table 1. Comparison of fault diagnosis methods

类型 诊断方法 故障类型 优缺点 知识驱动 专家系统[50-51] 跑偏、打滑、损伤、堆料撒料、滚筒故障 不需要数学模型,但知识库建立较难 故障树[23,53,64] 跑偏、打滑、损伤、堆料撒料、滚筒故障 因果关系清晰明了,但复杂系统故障树异常复杂 数据驱动 时频域分

析法[5,66]减速器故障、滚筒故障、托辊故障 计算简单快速,不需要滤波处理,且精度较高,

但不能分析随时间变化的信号最小熵

理论[8,35]滚筒故障 数据波动情况下精度较高,但易受噪声影响 BP、卷积神经网络[65,68] 减速器故障、托辊故障 准确度较高,但样本量直接决定模型精度 小波包分解法[67,69] 托辊故障、滚筒故障、减速器故障 可观察信号的局部特性,但冗余度较大 SVM [55,68] 托辊故障、损伤故障 鲁棒性好,但对于大容量样本,难以实现,运算量大 比差法[56] 打滑故障 简单直接,但是应用场景较少,且误差较大 音频特征分

析法[57-58,66-68]托辊故障、损伤故障 计算量较小,但易受外界噪声影响 视觉信息

分析法[14-15]跑偏故障、损伤故障、托辊故障 具有无损检测的优势,但计算量较大,易受外界因素影响 -

[1] 向秀华. 煤矿带式输送机智能故障诊断方法的研究[D]. 徐州: 中国矿业大学, 2017.XIANG Xiuhua. Research on intelligent fault diagnosis of coal mine belt conveyer[D]. Xuzhou: China University of Mining and Technology, 2017. [2] ZHOU Donghua,ZHAO Yinghong,WANG Zidong,et al. Review on diagnosis techniques for intermittent faults in dynamic systems[J]. IEEE Transactions on Industrial Electronics,2020:2337-2347. [3] 魏晓宾,马小平,李亚朋. 故障诊断技术综述[J]. 煤矿机电,2009,30(1):63-65.WEI Xiaobin,MA Xiaoping,LI Yapeng. Survey of fault diagnosis technology[J]. Colliery Mechanical & Electrical Technology,2009,30(1):63-65. [4] 周东华,胡艳艳. 动态系统的故障诊断技术[J]. 自动化学报,2009,35(6):748-758. doi: 10.3724/SP.J.1004.2009.00748ZHOU Donghua,HU Yanyan. Fault diagnosis techniques for dynamic systems[J]. Acta Automatica Sinica,2009,35(6):748-758. doi: 10.3724/SP.J.1004.2009.00748 [5] 孙振宇,王震坡,刘鹏,等. 新能源汽车动力电池系统故障诊断研究综述[J]. 机械工程学报,2021,57(14):87-104. doi: 10.3901/JME.2021.14.087SUN Zhenyu,WANG Zhenpo,LIU Peng,et al. Overview of fault diagnosis in new energy vehicle power battery system[J]. Journal of Mechanical Engineering,2021,57(14):87-104. doi: 10.3901/JME.2021.14.087 [6] 薛光辉,张军,吉晓冬,等. 井下带式输送机减速器振动故障诊断研究[J]. 工矿自动化,2014,40(6):51-53.XUE Guanghui,ZHANG Jun,JI Xiaodong,et al. Research of vibration fault diagnosis of underground belt conveyor gear reducer[J]. Industry and Mine Automation,2014,40(6):51-53. [7] DENG Xiaogang, ZHANG Zheng. Nonlinear chemical process fault diagnosis using ensemble deep support vector data description[J]. Sensors, 2020, 20(16). DOI: 10.3390/s20164599. [8] LI Xiangong, LI Yu, ZHANG Yuzhi, et al. Fault diagnosis of belt conveyor based on support vector machine and grey wolf optimization[J]. Mathematical Problems in Engineering, 2020. DOI: 10.1155/2020/1367078. [9] 王怡恬. 基于谱峭度和最小熵反卷积的轴承故障增强检测[D]. 长沙: 国防科技大学, 2017.WANG Yitian. Bearing fault enhancement detection based on spectral kurtosis and minimum entropy deconvolution[D]. Changsha: National University of Defense Technology, 2017. [10] 王荣杰. 带式输送机打滑事故原因及对策[J]. 矿山机械,2001,29(8):77.WANG Rongjie. Causes and countermeasures of belt conveyor slipping accident[J]. Mining & Processing Equipment,2001,29(8):77. [11] YANG Yanli,MIAO Changyun,LI Xianguo,et al. On-line conveyor belts inspection based on machine vision[J]. Optik,2014,125(19):5803-5807. doi: 10.1016/j.ijleo.2014.07.070 [12] YU Binchao,QIAO Tiezhu,ZHANG Haitao,et al. Dual band infrared detection method based on mid-infrared and long infrared vision for conveyor belts longitudinal tear[J]. Measurement,2018,120:140-149. doi: 10.1016/j.measurement.2018.02.029 [13] QIAO Tiezhu,CHEN Lulu,PANG Yusong,et al. Integrative binocular vision detection method based on infrared and visible light fusion for conveyor belts longitudinal tear[J]. Measurement,2017,110:192-201. doi: 10.1016/j.measurement.2017.06.032 [14] QIAO Tiezhu,LIU Weili,PANG Yusong,et al. Research on visible light and infrared vision real-time detection system for conveyor belt longitudinal tear[J]. Iet Science Measurement & Technology,2016,10(6):577-584. [15] HOU Chengcheng,QIAO Tiezhu,ZHANG Haitao,et al. Multispectral visual detection method for conveyor belt longitudinal tear[J]. Measurement,2019,143:246-257. doi: 10.1016/j.measurement.2019.05.010 [16] 付胜,刘毅. 带式输送机输送带纵向撕裂线激光辅助视觉检测方法[J]. 矿山机械,2016,44(6):31-35.FU Sheng,LIU Yi. Linear laser aided vision inspection method for longitudinal rip of conveyor belt[J]. Mining & Processing Equipment,2016,44(6):31-35. [17] 潘学文,张福生,路超. 基于故障树的故障诊断专家系统设计[J]. 煤矿机械,2021,42(3):174-176.PAN Xuewen,ZHANG Fusheng,LU Chao. Design of fault diagnosis expert system based on fault tree[J]. Coal Mine Machinery,2021,42(3):174-176. [18] 陈作炳,刘阳. 基于B/S架构及专家系统的带式输送机远程监控系统设计[J]. 煤矿机械,2021,42(5):202-205.CHEN Zuobing,LIU Yang. Design of remote monitoring system for belt conveyor based on B/S architecture and expert system[J]. Coal Mine Machinery,2021,42(5):202-205. [19] 刘强,尹同舟,唐秀山,等. 掘进机截割系统的故障树-层次分析法诊断分析[J]. 煤炭科学技术,2017,45(3):123-127.LIU Qiang,YIN Tongzhou,TANG Xiushan,et al. Diagnosis analysis on fault tree-analytic hierarchy process of roadheader cutting system[J]. Coal Science and Technology,2017,45(3):123-127. [20] 彭华亮,沈暑龙,李军,等. 基于故障树的故障诊断专家系统设计[J]. 控制工程,2019,26(3):584-588.PENG Hualiang,SHEN Shulong,LI Jun,et al. Design of diagnostic expert system for launch vehicles based on FTA[J]. Control Engineering of China,2019,26(3):584-588. [21] JEINSCH T, SADER M, NOACK R, et al. A robust model-based information system for monitoring and fault detection of large scale belt conveyor systems[C]. The 4th world congress on intelligent control and automation, Shanghai, 2002: 3283-3287. [22] RAVIKUMAR S,KANAGASABAPATHY H,MURALIDHARAN V. Fault diagnosis of self-aligning troughing rollers in belt conveyor system using k-star algorithm[J]. Measurement,2018,133:341-349. [23] 汪列文. 基于故障树分析的输送带跑偏故障研究[D]. 秦皇岛: 燕山大学, 2019.WANG Liewen. Study on the deviation fault of conveyor belt based on fault tree analysis[D]. Qinhuangdao: Yanshan University, 2019. [24] 武晓斌. 带式输送机跑偏故障治理技术研究[J]. 自动化应用,2020,61(6):153-154,156.WU Xiaobin. Research on treatment technology of belt conveyor deviation fault[J]. Automation Application,2020,61(6):153-154,156. [25] 闫峰. 带式输送机跑偏故障综合治理措施研究[J]. 机械工程与自动化,2020(1):194-195,198.YAN Feng. Research on comprehensive treatment measures for belt conveyor deviation[J]. Mechanical Engineering & Automation,2020(1):194-195,198. [26] 崔融融. 带式输送机故障自动巡检机器人系统设计[J]. 煤矿机械,2021,42(3):15-18.CUI Rongrong. Design of automatic fault inspection robot system for belt conveyor[J]. Coal Mine Machinery,2021,42(3):15-18. [27] 胡雪. 带式输送机工作状态分析与故障预警方法研究[D]. 沈阳: 沈阳工业大学, 2021.HU Xue. Research on the working status analysis and fault early warning method of belt conveyor[D]. Shenyang: Shenyang University of Technology, 2021. [28] 朱艳军,任晓迪,席冉. 煤矿主运输带式输送机故障监测和防治系统研究[J]. 中国煤炭,2014,40(4):73-75.ZHU Yanjun,REN Xiaodi,XI Ran. Research on fault monitoring and controlling system of main belt conveyor in coal mine[J]. China Coal,2014,40(4):73-75. [29] 井坤. 基于红外图像处理的带式输送机故障诊断系统研究[D]. 曲阜: 曲阜师范大学, 2021.JING Kun. Research on fault diagnosis system of belt conveyor based on infrared image processing[D]. Qufu: Qufu Normal University, 2021. [30] LI Jie,MIAO Changyun. The conveyor belt longitudinal tear on-line detection based on improved SSR algorithm[J]. Optik,2016,127(19):8002-8010. doi: 10.1016/j.ijleo.2016.05.111 [31] ZHANG Chuanwei, ZHANG Junnan. Detection of longitudinal belt rip based on canny operator[C]. International Conference on Computer Technology, Electronics and Communication, Guangzhou, 2017: 939-941. [32] 康宏. 矿井带式输送机故障的分析与处理[J]. 煤矿机械,2009,30(1):172-174.KANG Hong. Malfunction analysis and disposal of mine belt conveyer[J]. Coal Mine Machinery,2009,30(1):172-174. [33] 冯全兴,于庆龙. 带式输送机常见故障分析与处理[J]. 科技创新导报,2011,8(20):60.FENG Quanxing,YU Qinglong. Analysis and treatment of common faults of belt conveyor[J]. Science and Technology Innovation Herald,2011,8(20):60. [34] 李小元,周久华. 神东矿区带式输送机故障统计分析[J]. 矿山机械,2014,42(6):136-138.LI Xiaoyuan,ZHOU Jiuhua. Statistical analysis of belt conveyor faults in Shendong mining area[J]. Mining & Processing Equipment,2014,42(6):136-138. [35] 冷军发,郭松涛,荆双喜,等. 基于最小熵解卷积的带式输送机传动滚筒轴承故障诊断[J]. 河南理工大学学报(自然科学版),2015,34(4):514-519.LENG Junfa,GUO Songtao,JING Shuangxi,et al. Rolling element bearing fault diagnosis of belt conveyor driving drum based on minimum entropy deconvolution[J]. Journal of Henan Polytechnic University(Natural Science),2015,34(4):514-519. [36] 姚艳萍,孟文俊,王细平. 煤矿带式输送机改向滚筒故障分析[J]. 煤矿机械,2014,35(3):252-254.YAO Yanping,MENG Wenjun,WANG Xiping. Failure analysis of belt conveyor bend pulley in coal mine[J]. Coal Mine Machinery,2014,35(3):252-254. [37] 张强. 基于新型检测方法的带式输送机滚筒故障诊断[J]. 机械管理开发,2022,37(6):144-145,151.ZHANG Qiang. Fault diagnosis of belt conveyor roller based on new detection method[J]. Mechanical Management and Development,2022,37(6):144-145,151. [38] 任勇. 煤矿带式输送机的常见故障与原因分析[J]. 现代矿业,2019,35(4):147-148.REN Yong. Analysis of common faults and causes of coal mine belt conveyor[J]. Modern Mining,2019,35(4):147-148. [39] LIU Xiangwei,PANG Yusong,LODEWIJKS G,et al. Experimental research on condition monitoring of belt conveyor idlers[J]. Measurement,2018,127:277-282. doi: 10.1016/j.measurement.2018.04.066 [40] SHIRI H, WODECKI J, ZIETEK B, et al. Inspection robotic UGV platform and the procedure for an acoustic signal-based fault detection in belt conveyor idler[J]. Energies, 2021, 14(22). DOI: 10.3390/en14227646. [41] GŁADYSIEWICZ L,KRÓL R,KISIELEWSKI W. Measurements of loads on belt conveyor idlers operated in real conditions[J]. Measurement,2018,134:336-344. [42] 韩龙. 煤矿皮带运输机的减速装置断轴分析及改进[J]. 机械管理开发,2018,33(8):285-287.HAN Long. Analysis and improvement of shaft breaking of deceleration device of belt conveyer in coal mine[J]. Mechanical Management and Development,2018,33(8):285-287. [43] 姚少波. 矿用带式输送机减速机断轴原因分析与改进措施研究[J]. 机电工程技术,2020,49(6):199-200. doi: 10.3969/j.issn.1009-9492.2020.06.080YAO Shaobo. Analysis and improvement of shafts broken of mine belt conveyor reducer[J]. Mechanical & Electrical Engineering Technology,2020,49(6):199-200. doi: 10.3969/j.issn.1009-9492.2020.06.080 [44] 陈志矿. 浅谈小煤矿皮带运输机常见故障的处理方法[J]. 科技信息,2011(14):697.CHEN Zhikuang. Brief discussion on the treatment of common faults of belt conveyor in small coal mines[J]. Science & Technology Information,2011(14):697. [45] 何宝泉,王彬. 带式输送机减速器的轴承故障诊断[J]. 煤矿机械,2013,34(10):256-257.HE Baoquan,WANG Bin. Bearing fault diagnosis belt conveyor reducer[J]. Coal Mine Machinery,2013,34(10):256-257. [46] 宋钦一. 基于故障树和贝叶斯网络的带式输送机故障诊断[J]. 矿山机械,2022,50(9):55-58.SONG Qinyi. Fault diagnosis on belt conveyor based on fault tree and Bayesian network[J]. Mining & Processing Equipment,2022,50(9):55-58. [47] 宋康康. 带式输送机输送带故障智能监测保护系统的设计[J]. 机械管理开发,2020,35(5):193-195.SONG Kangkang. Design of intelligent monitoring and protection system for belt conveyor belt fault[J]. Mechanical Management and Development,2020,35(5):193-195. [48] 周东华,纪洪泉,何潇. 高速列车信息控制系统的故障诊断技术[J]. 自动化学报,2018,44(7):1153-1164.ZHOU Donghua,JI Hongquan,HE Xiao. Fault diagnosis techniques for the information control system of high-speed trains[J]. Acta Automatica Sinica,2018,44(7):1153-1164. [49] XIAO Yanjun,HAN Furong. Research on fault diagnosis method of rapier loom based on the fusion of expert system and fault tree[J]. Journal of Intelligent & Fuzzy Systems,2021,41(2):3429-3441. [50] 宋新扩. 带式输送机故障分析及其诊断系统设计研究[D]. 徐州: 中国矿业大学, 2019.SONG Xinkuo. Fault analysis and diagnosis system design of belt conveyor[D]. Xuzhou: China University of Mining and Technology, 2019. [51] 张学舜. 带式输送机监测监控及故障诊断专家系统的设计及应用[J]. 机械管理开发,2022,37(8):164-165,168.ZHANG Xueshun. Design and application of an expert system for monitoring and fault diagnosis of belt conveyors[J]. Mechanical Management and Development,2022,37(8):164-165,168. [52] 金鑫,任献彬,周亮. 智能故障诊断技术研究综述[J]. 国外电子测量技术,2009,28(7):30-32.JIN Xin,REN Xianbin,ZHOU Liang. Overview on intelligent technology of fault diagnosis[J]. Foreign Electronic Measurement Technology,2009,28(7):30-32. [53] 高文博. 静态故障树分析法在皮带机胶带故障检测中的应用[J]. 江西煤炭科技,2016(3):134-136,140.GAO Wenbo. Application of static fault tree method to belt fault detection in belt conveyor[J]. Jiangxi Coal Science & Technology,2016(3):134-136,140. [54] 刘宏达,汉京勇,申乃军,等. 基于支持向量机的SCR整流电路故障诊断方法[J]. 船舶工程,2012,34(6):25-29.LIU Hongda,HAN Jingyong,SHEN Naijun,et al. Fault diagnosis method for SCR rectifier circuit based on support vector machines[J]. Ship Engineering,2012,34(6):25-29. [55] 蒋权,甄晓阳,王晓辉,等. 输送带跑偏故障的原因及诊断[J]. 机械工程与自动化,2014(1):141-143.JIANG Quan,ZHEN Xiaoyang,WANG Xiaohui,et al. Reasons and fault diagnosis of conveyor belt running deviation[J]. Mechanical Engineering & Automation,2014(1):141-143. [56] 马晶晶. 带式输送机运行状态综合监测研究[D]. 青岛: 青岛理工大学, 2013.MA Jingjing. Research on comprehensive monitoring of belt conveyor running state[D]. Qingdao: Qingdao University of Technology, 2013. [57] 苗长云,邵琦. 基于声音的带式输送机输送带纵向撕裂检测方法[J]. 天津工业大学学报,2021,40(6):70-75,82.MIAO Changyun,SHAO Qi. Detection method of longitudinal tear of belt conveyor belt based on sound[J]. Journal of Tianjin Polytechnic University,2021,40(6):70-75,82. [58] 祁隽燕,谭超,李浩. 基于数字图像处理的皮带纵向撕裂视觉识别[J]. 煤炭技术,2006,25(11):15-17. doi: 10.3969/j.issn.1008-8725.2006.11.007QI Junyan,TAN Chao,LI Hao. Vision identification for longitudinal rip of steel-cord belt based on digital image process[J]. Coal Technology,2006,25(11):15-17. doi: 10.3969/j.issn.1008-8725.2006.11.007 [59] 祁隽燕,闫海峰,谭超,等. 基于LabVIEW的胶带撕裂机器视觉检测系统研究[J]. 煤炭工程,2009,41(9):123-125.QI Junyan,YAN Haifeng,TAN Chao,et al. Machine vision inspection system of belt tearing base on LabVIEW[J]. Coal Engineering,2009,41(9):123-125. [60] PENG Xiaoming. A novel image-based method for conveyor belt rip detection[C]. IEEE International Conference on Signal Processing, Communication and Computing, Kunming, 2013: 1-4. [61] HOMIŠIN J,GREGA R,KAŠŠAY P,et al. Removal of systematic failure of belt conveyor drive by reducing vibrations[J]. Engineering Failure Analysis,2019,99:192-202. doi: 10.1016/j.engfailanal.2019.02.028 [62] 陈劭康. 带式输送机故障预测与健康状态评估技术研究[D]. 徐州: 中国矿业大学, 2021.CHEN Shaokang. Research on fault prediction and health assessment technology of belt conveyor[D]. Xuzhou: China University of Mining and Technology, 2021. [63] 崔扬扬. 可伸缩带式输送机故障诊断与对策[D]. 邯郸: 河北工程大学, 2013.CUI Yangyang. Fault diagnosis and countermeasure of telescopic belt conveyor[D]. Handan: Hebei University of Engineering, 2013. [64] 于淑政,崔扬扬,曹艳芳. 带式输送机故障分析与处理[J]. 煤矿机械,2012,33(10):282-284.YU Shuzheng,CUI Yangyang,CAO Yanfang. Analysis and treatment of belt type conveyor fault[J]. Coal Mine Machinery,2012,33(10):282-284. [65] 闫来清. 矿用带式输送机减速器故障诊断方法研究[J]. 电气应用,2014,33(23):82-85.YAN Laiqing. Research on fault diagnosis method for reducer of mining belt conveyor[J]. Electrotechnical Application,2014,33(23):82-85. [66] LIU Yi, MIAO Changyun, LI Xianguo, et al. Research on the fault analysis method of belt conveyor idlers based on sound and thermal infrared image features[J]. Measurement, 2021, 186. DOI: 10.1016/j.measurement.2021.110177. [67] LI Wei, WANG Zewen, ZHU Zhencai, et al. Design of online monitoring and fault diagnosis system for belt conveyors based on wavelet packet decomposition and support vector machine[J]. Advance in Mechanical Engineering, 2013. DOI: 10.1155/2013/797183. [68] YANG Mingjin,ZHOU Wenju,SONG Tianxiang. Audio-based fault diagnosis for belt conveyor rollers[J]. Neurocompting,2020,397:47-56. [69] 曹贯强. 带式输送机托辊故障检测方法[J]. 工矿自动化,2020,46(6):81-86.CAO Guanqiang. Fault detection method for belt conveyor roller[J]. Industry and Mine Automation,2020,46(6):81-86. -

下载:

下载: