Degradation monitoring and fault diagnosis of mining cables based on current harmonic features

-

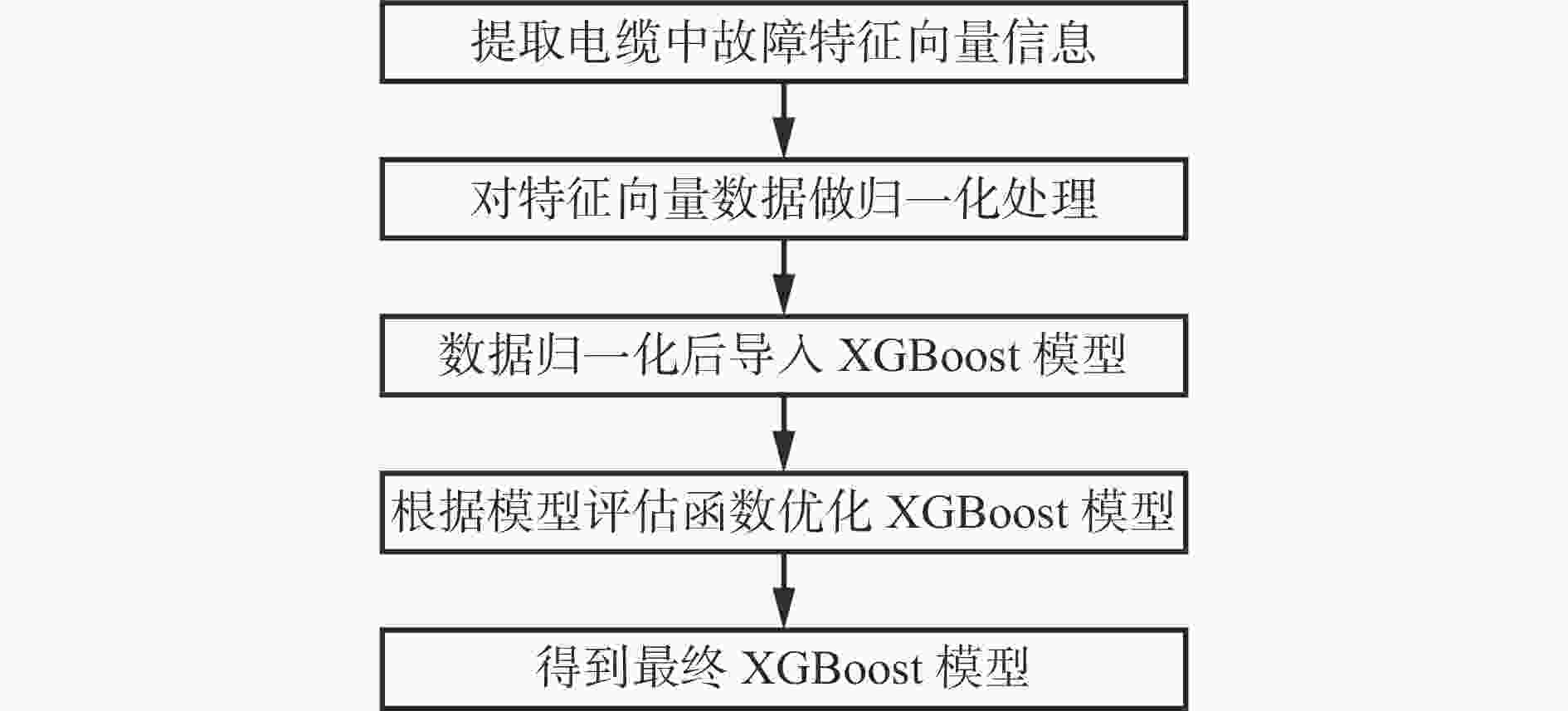

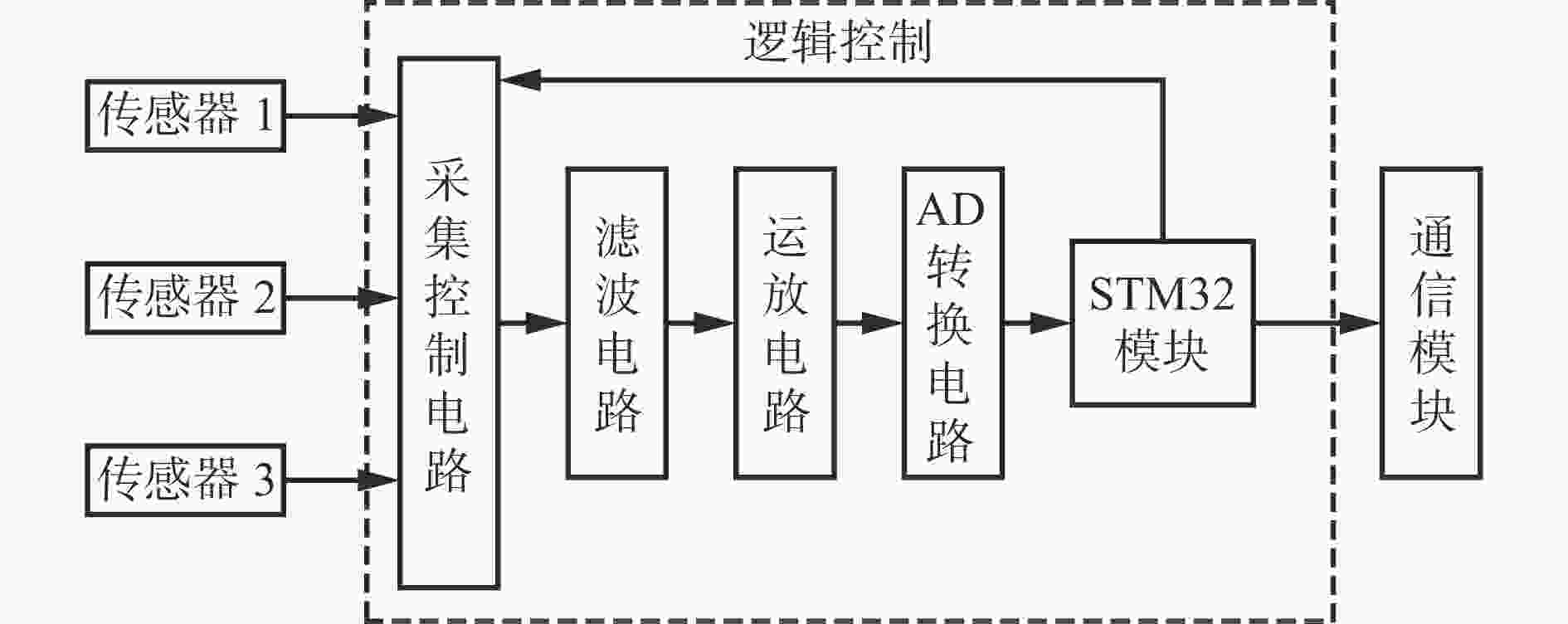

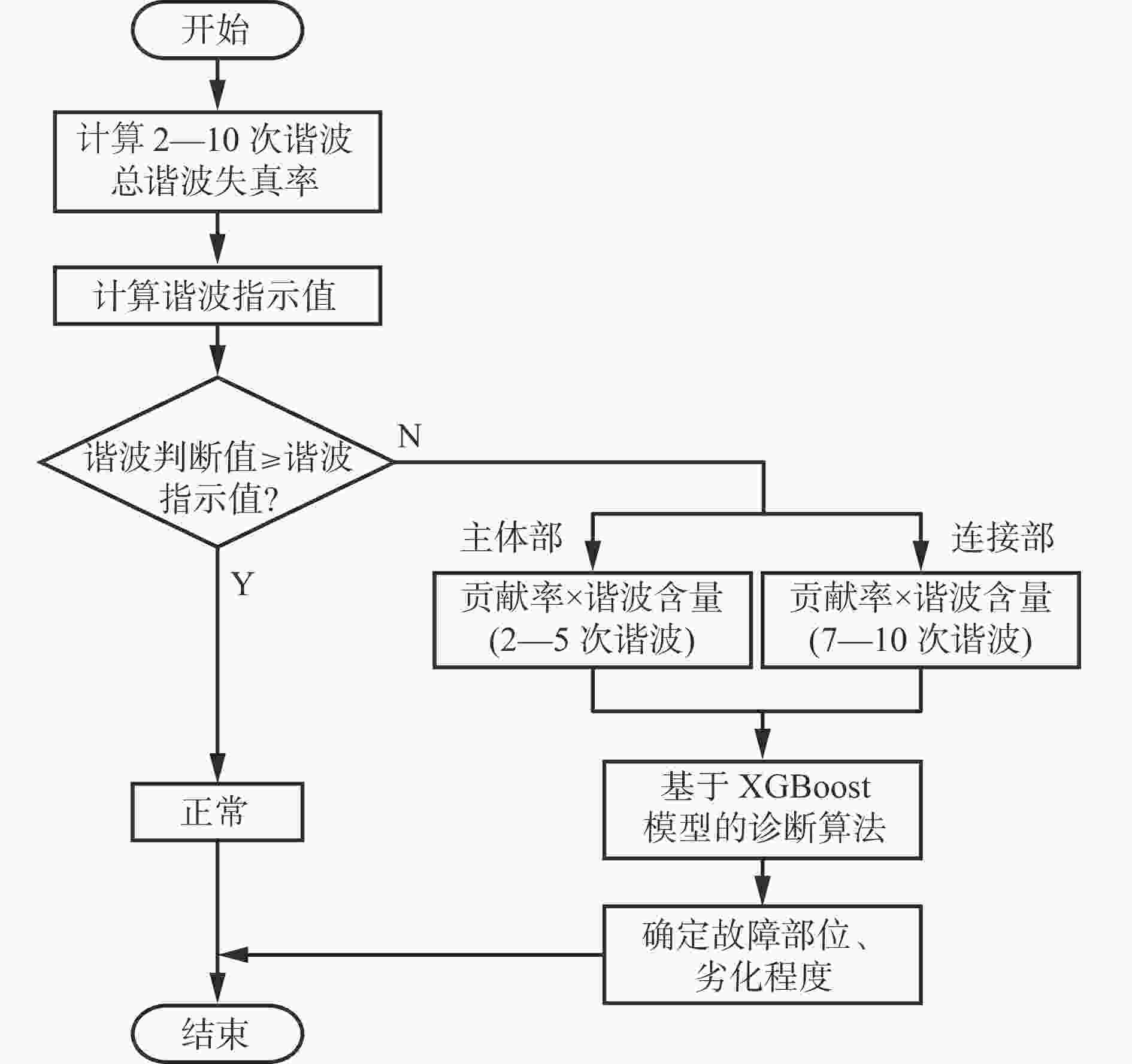

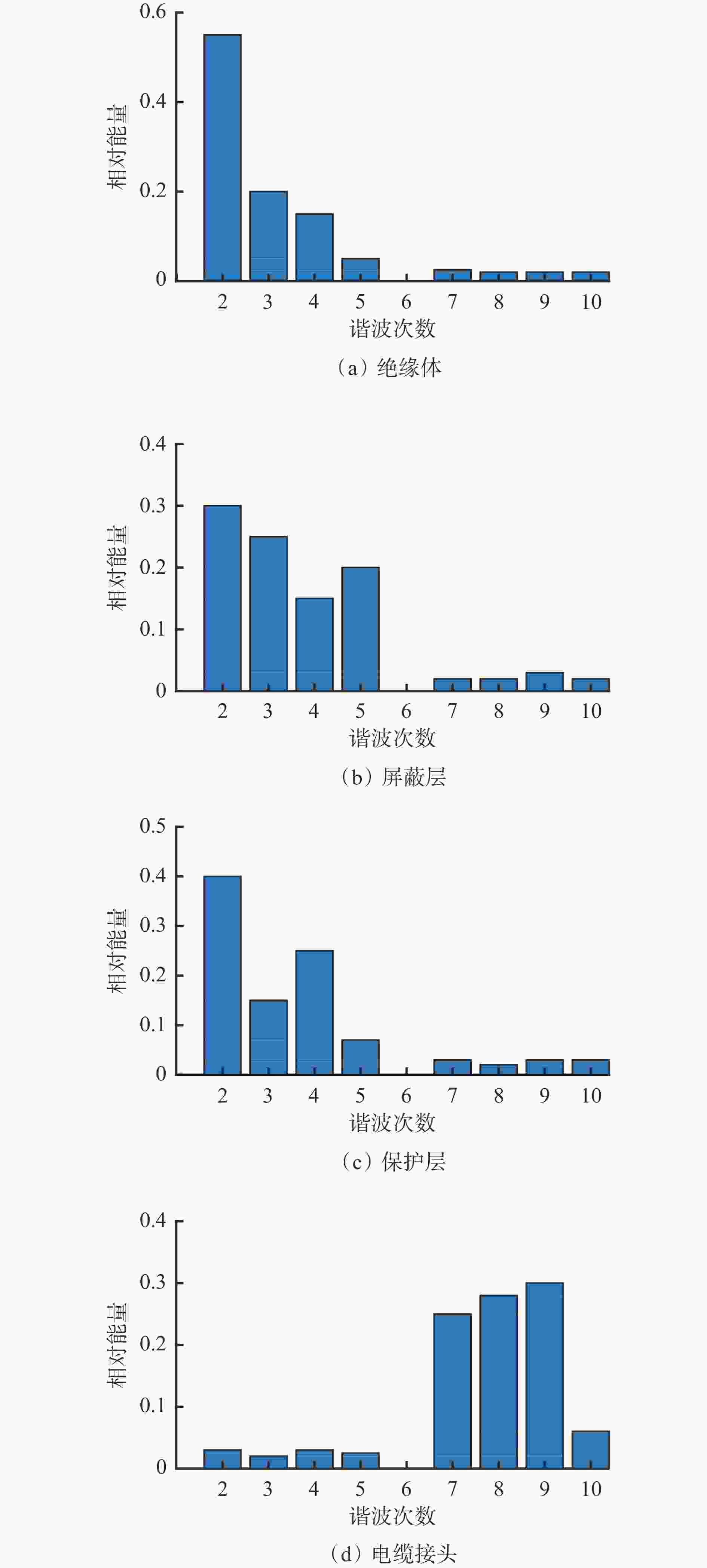

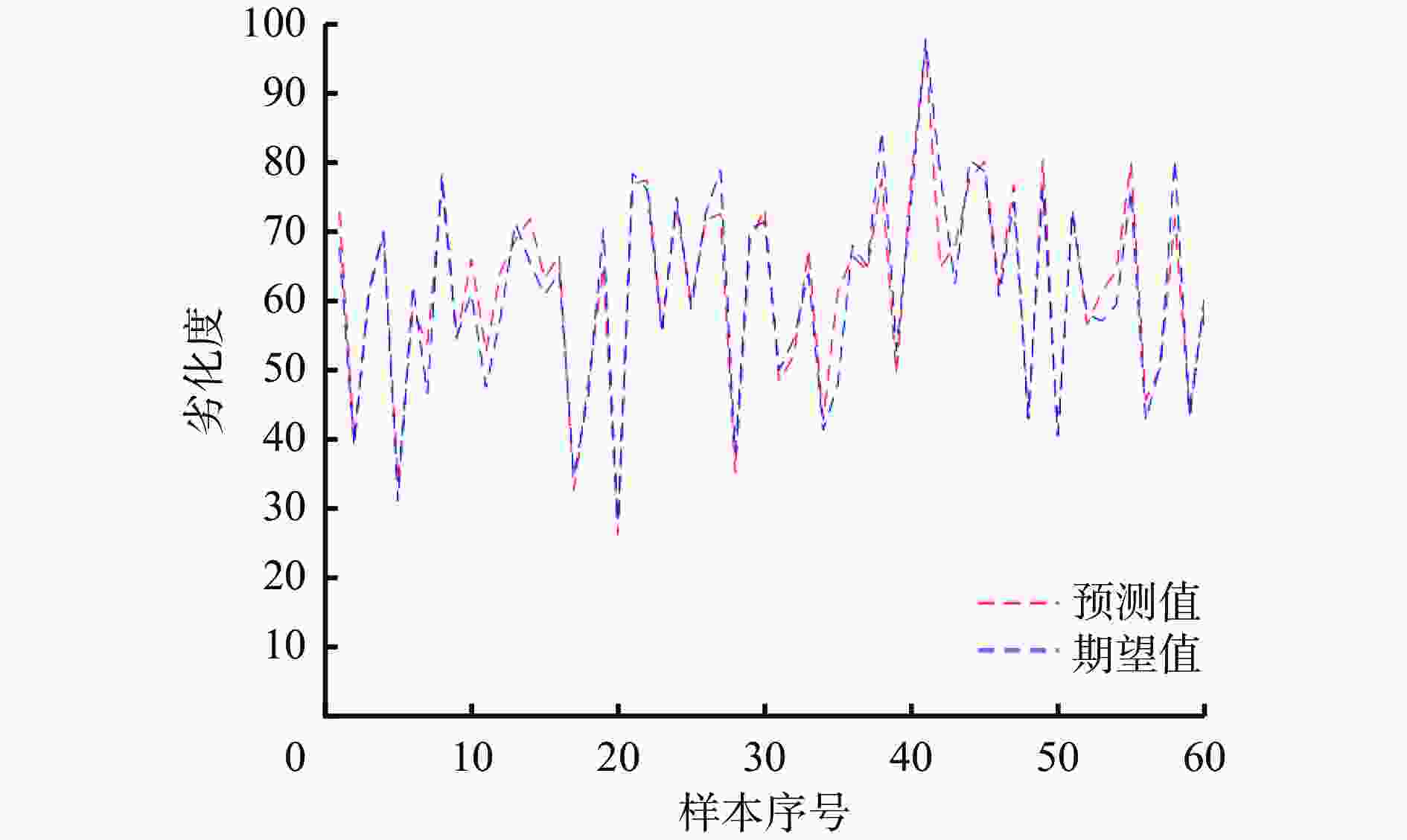

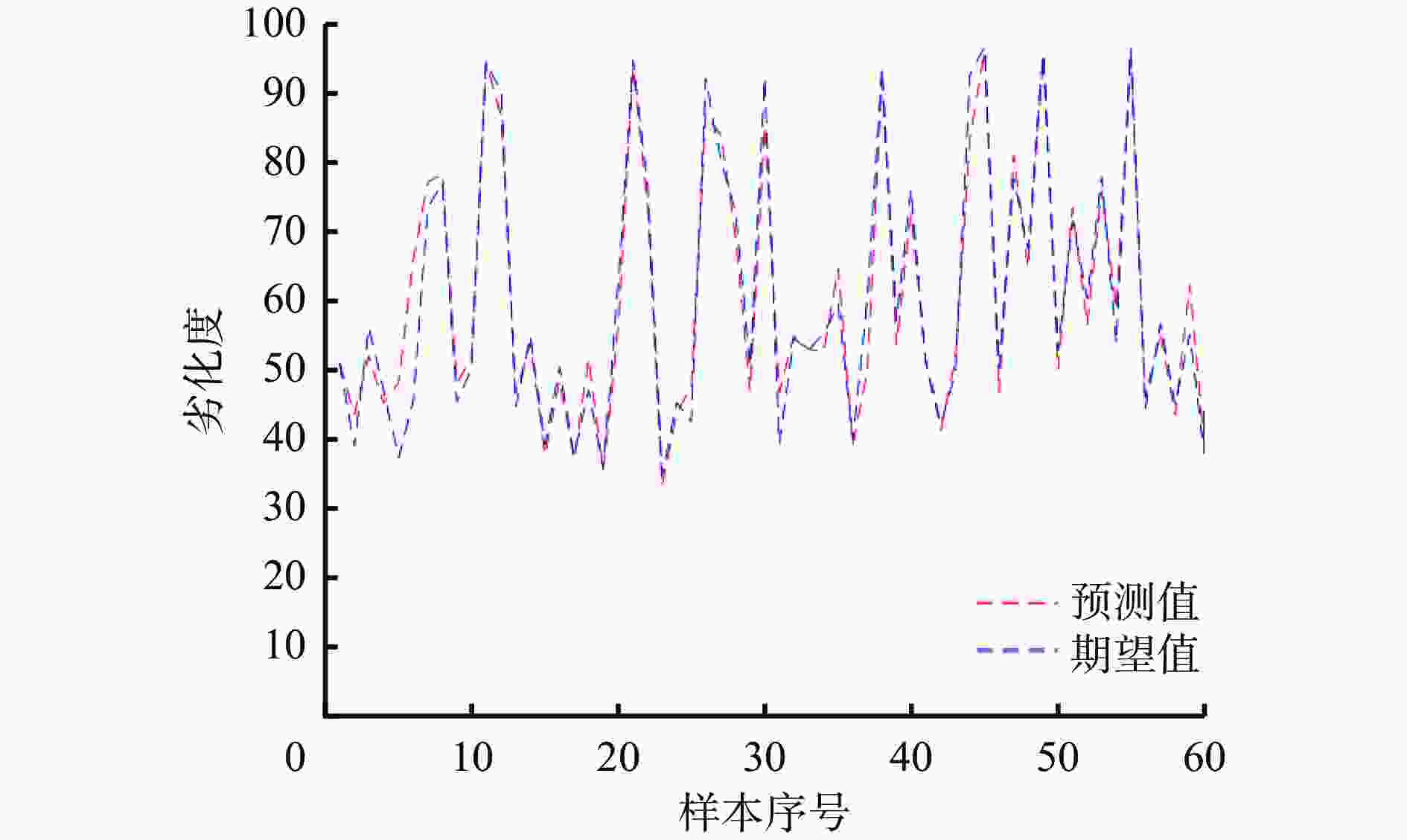

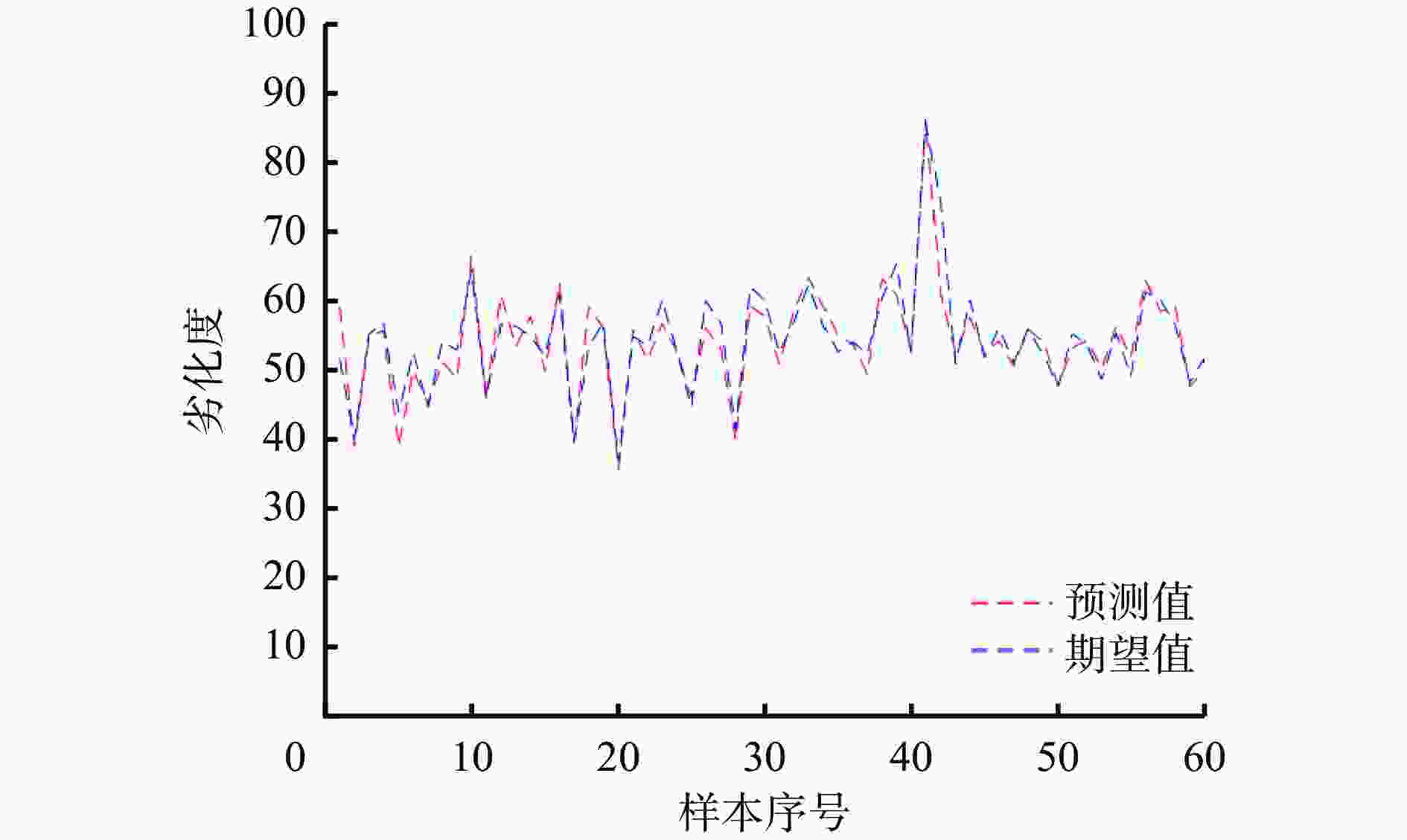

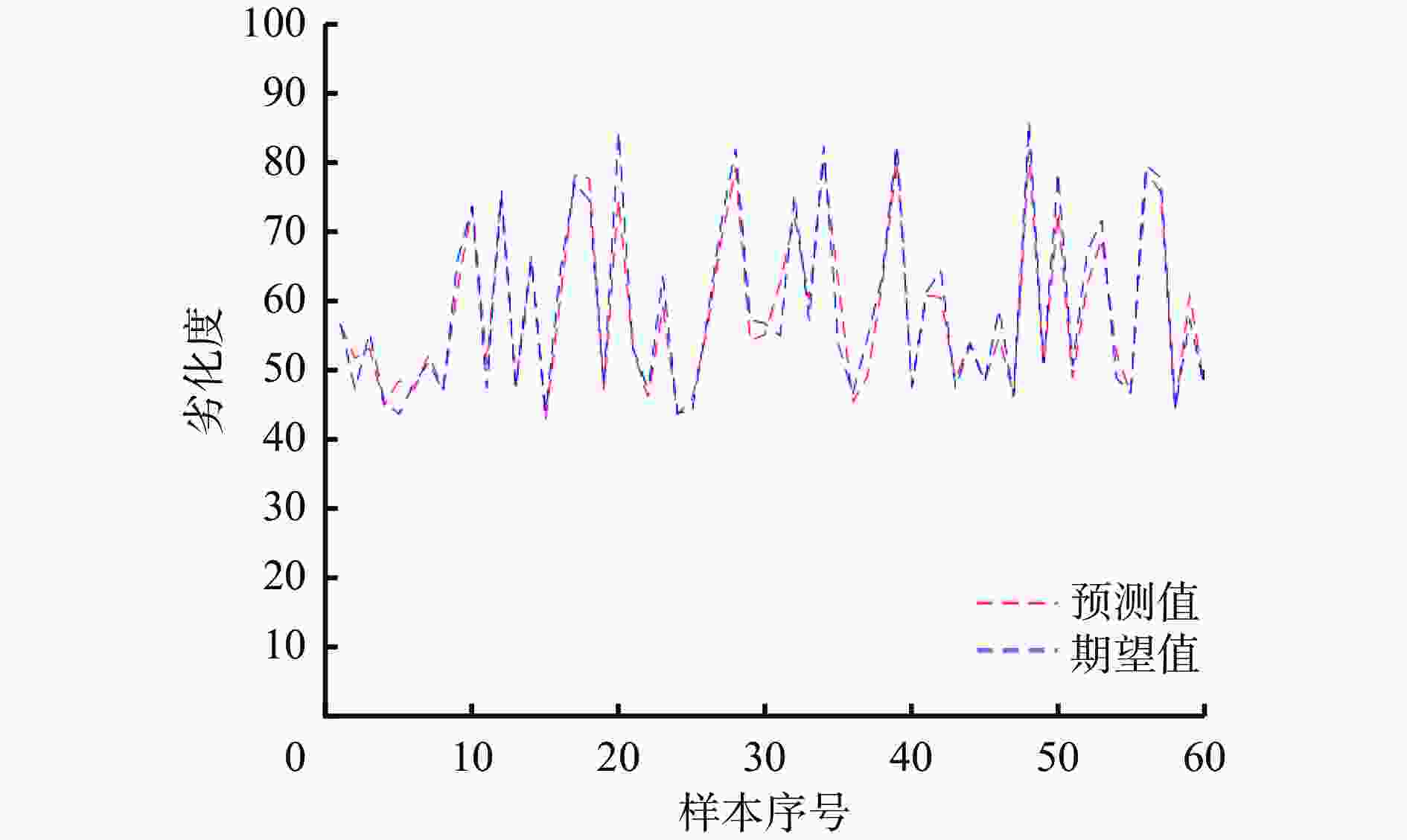

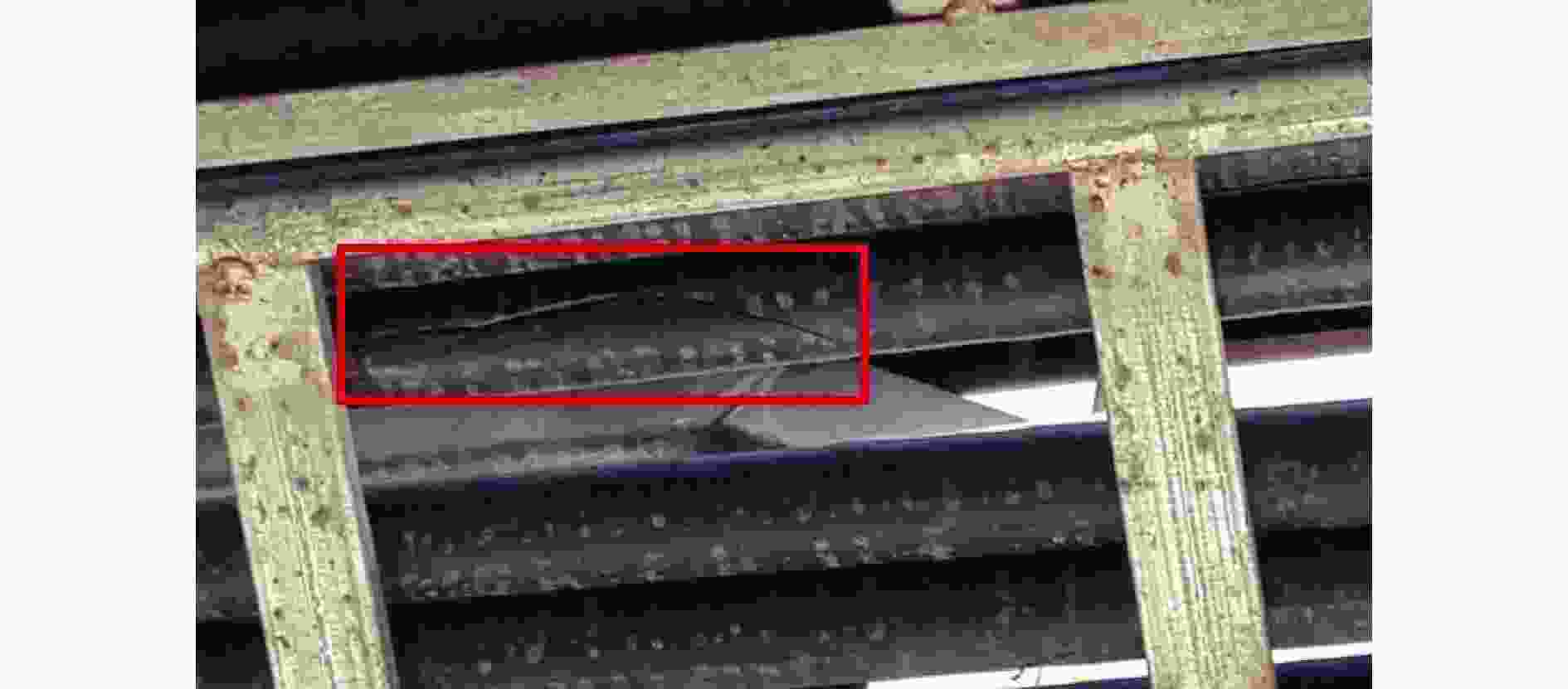

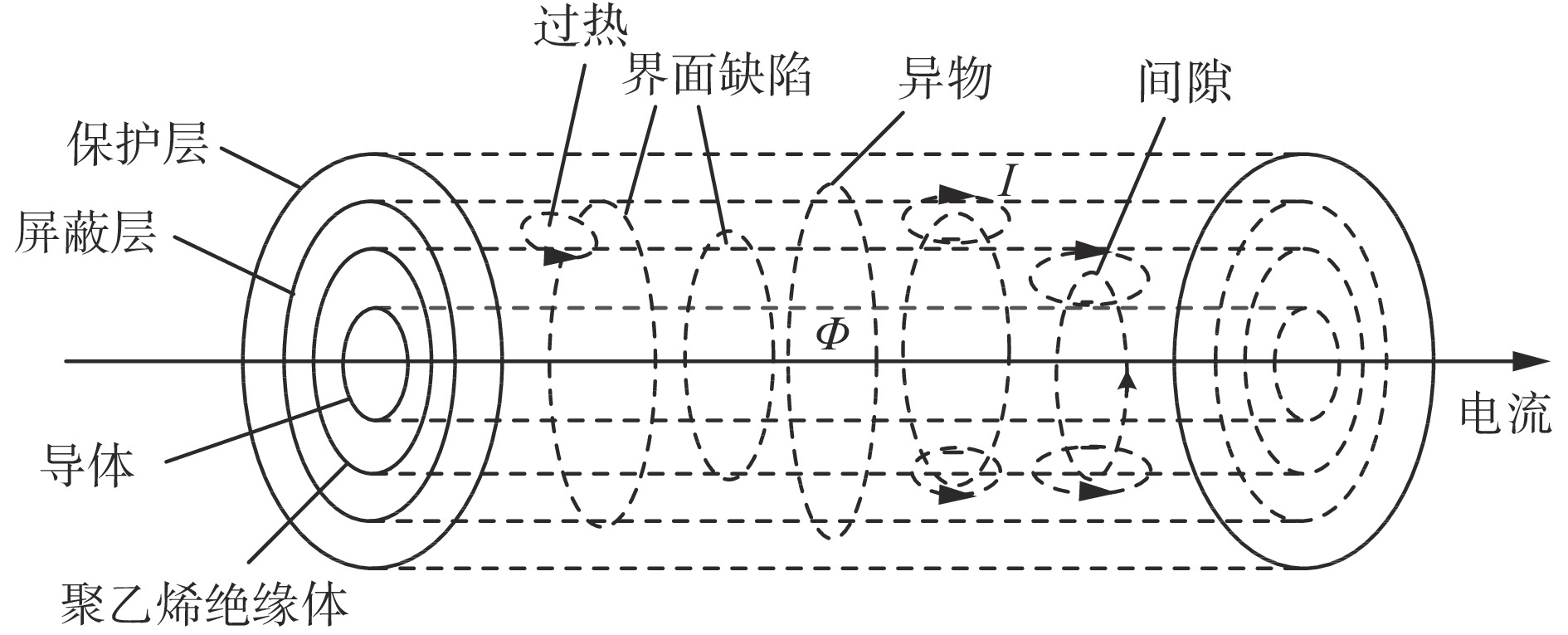

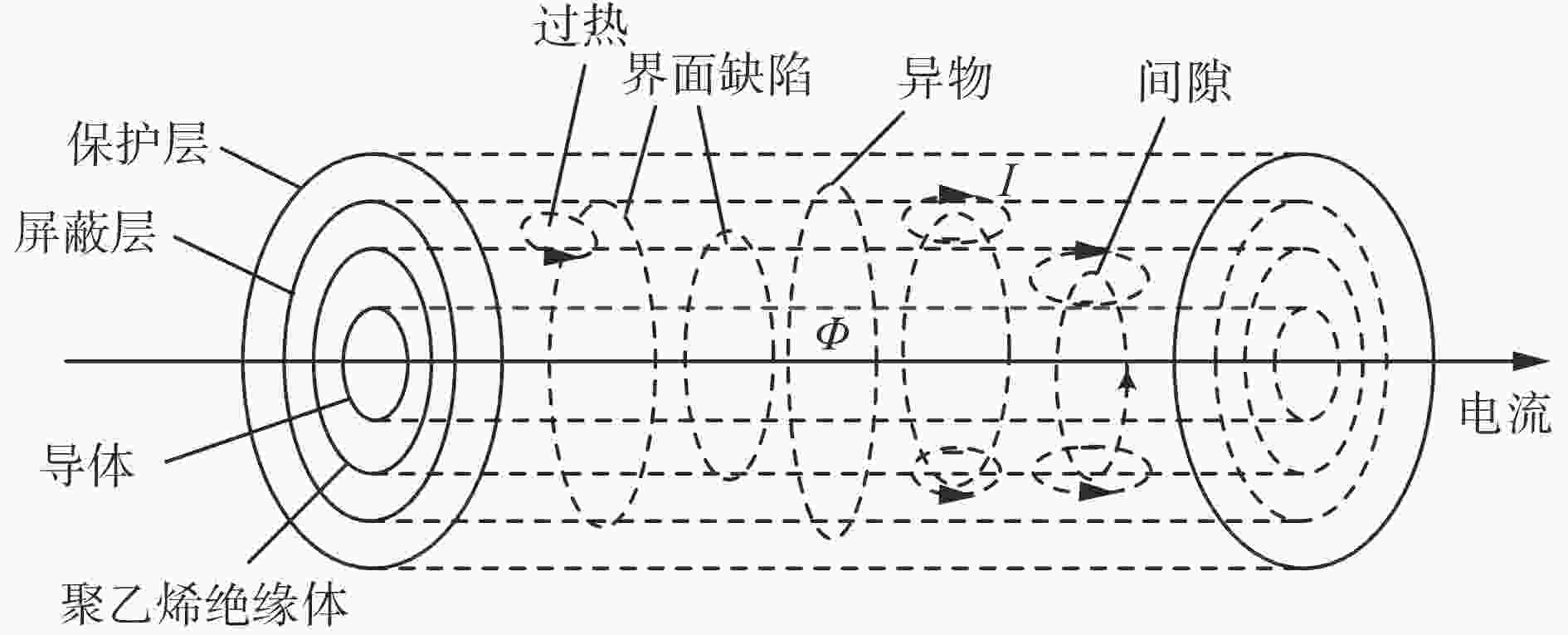

摘要: 矿用电缆受煤矿恶劣环境影响,容易发生绝缘劣化、护套受损等情况,传统的矿用电缆检测多采用低压脉冲法、局放法等离线诊断方式,操作复杂,准确度低,难以满足现代煤矿生产需求。而现有基于谐波的电缆故障诊断方法存在检测装置笨重、检测精确低、难以在煤矿应用等问题。针对上述问题,提出一种基于电流谐波特征的矿用电缆劣化监测与故障诊断方法。提取电缆中高次谐波含量信息作为故障特征向量,对特征向量进行归一化处理后导入极限梯度提升树(XGBoost)模型,结合已知电缆故障劣化度数据,形成训练样本集,训练XGBoost模型,最后通过构建的XGBoost模型对电缆劣化度进行实时监测和故障诊断。仿真结果表明:针对电缆不同部位提取的高次谐波向量的相对能量有明显不同,表明提取的高次谐波向量可表征电缆不同部位的运行状态;XGBoost模型的拟合优度参数R2高达 0.93,且误差较小。案例分析结果验证了基于电流谐波特征的矿用电缆劣化监测与故障诊断方法可对矿用电缆运行状态及劣化故障进行实时、准确的监测和诊断。Abstract: Mining cables are affected by the harsh environment of coal mines, and are prone to insulation degradation and sheath damage. The traditional offline diagnostic methods such as low-voltage pulse method and partial discharge method are often used for detecting mining cables. The methods are complex to operate and have low accuracy, making it difficult to meet the needs of modern coal mine production. However, the existing harmonic based cable fault diagnosis methods have problems such as bulky detection devices, low detection precision, and difficulty in application in coal mines. In order to solve the above problems, a degradation monitoring and diagnosing method of mining cables based on current harmonic features is proposed. The method extracts high-order harmonic content information in cables as fault feature vectors, normalize the feature vectors, and then import them into extreme gradient boost tree (XGBoost) model. Combined with known cable fault degradation value data, a training sample set is formed to train the XGBoost model. Finally, the method uses the constructed XGBoost model to monitor and diagnose cable degradation in real-time. The simulation results show that the relative energy of the extracted high-order harmonic vectors from different parts of the cable is significantly different. The extracted high-order harmonic vectors can characterize the operating status of different parts of the cable. The goodness of fit parameter R2 of the XGBoost model is as high as 0.93, and the error is small. The case analysis results verify that the degradation monitoring and fault diagnosis method of mining cables based on current harmonic features can provide real-time and accurate monitoring and diagnosis of the operation status and degradation faults of mining cables.

-

表 1 矿用电缆劣化状态与高次谐波的关系

Table 1. Relationship between mining power cable degradation state and higher harmonics

电力电

缆部位劣化类型 第一主成分

谐波次数(贡献率)其他主成分

谐波次数(贡献率)累计故障

贡献率/%主体部 绝缘体劣化 初期劣化型 3(41%),5(41%) 4(6%),2(6%) 94 机械性损伤 2(55%) 4(16%),3(9%),5(6%) 86 电气性损伤 5(59%) 3(20%),4(8%),2(6%) 93 自然劣化型 5(52%) 3(28%),4(7%),2(6%) 93 屏蔽层劣化 3(25%) 5(24%),2(23%),4(18%) 90 保护层劣化 2(39%) 4(29%),3(10%),5(7%) 85 连接部 发热 7(53%) 10(15%),9(11%),8(7%),6(5%) 91 污损 8(35%) 7(29%),9(13%),10(11%),6(7%) 95 龟裂 9(33%) 8(25%),7(21%),10(8%),6(5%) 92 变形 10(30%) 7(23%),8(17%),9(15%),6(6%) 91 表 2 部分主体部样本数据

Table 2. Part of the main body sample data

序号 H2 H3 H4 H5 劣化度 绝缘体 屏蔽层 保护层 1 1.8 2.3 1.5 4.9 36.8 61.2 52.2 2 2.4 2.1 1.4 5.3 37.8 54.1 47.7 3 3.8 1.7 1.8 0.9 76.8 31.6 46.2 4 3.4 2.1 1.4 2.4 63.0 49.9 49.9 5 2.0 2.1 1.6 4.9 39.3 58.5 56.4 6 2.9 1.3 1.2 2.3 75.0 43.8 67.6 7 3.0 4.4 1.2 4.2 78.4 84.1 71.2 8 3.0 6.0 1.0 2.1 78.2 95.7 54.0 9 2.8 1.0 1.5 2.5 19.7 16.0 26.1 10 2.8 1.5 1.0 0.5 69.0 41.4 48.7 11 3.0 5.3 0.9 1.9 84.0 94.0 55.7 12 3.0 1.4 1.7 5.9 49.7 42.9 70.2 13 2.8 1.4 1.2 1.6 57.8 39.5 47.9 14 2.4 1.1 1.1 1.9 44.6 38.1 46.8 15 2.9 5.7 0.9 1.5 78.1 95.4 50.6 表 3 部分连接部样本数据

Table 3. Part of the connection part sample data

序号 H7 H8 H9 H10 电缆接头

劣化度1 1.2 0.4 0.4 0.4 82.6 2 1.5 0.6 0.5 0.5 81.3 3 1.2 0.4 0.5 0.7 78.8 4 0.6 0.5 0.4 0.3 47.7 5 0.7 0.5 0.4 0.4 46.2 6 0.5 0.4 0.3 0.2 49.9 7 0.7 0.4 0.3 0.2 56.4 8 0.5 0.5 0.5 0.5 67.6 9 0.8 0.4 0.4 0.4 71.2 10 0.6 0.5 0.4 0.4 54.0 11 0.5 0.4 0.4 0.2 46.1 12 0.6 0.4 0.4 0.2 46.7 13 0.6 0.4 0.4 0.3 55.7 14 0.8 0.6 0.5 0.3 70.2 15 0.7 0.4 0.4 0.3 47.9 表 4 电缆主体部和连接部预测精度评估参数

Table 4. Prediction accuracy evaluation parameters for cable main body and connection parts

电缆 R2 ${\rm{MSE}}$ ${\rm{MRSE}}$ ${\rm{MAPE}}$ 绝缘层 0.9354 0.001824 0.0422 0.0670 屏蔽层 0.9295 0.000798 0.0282 0.0468 保护层 0.9385 0.001736 0.0412 0.0607 电缆接头 0.9510 0.000959 0.0310 0.0286 表 5 部分高次谐波含有率

Table 5. Part of the high-order harmonic content

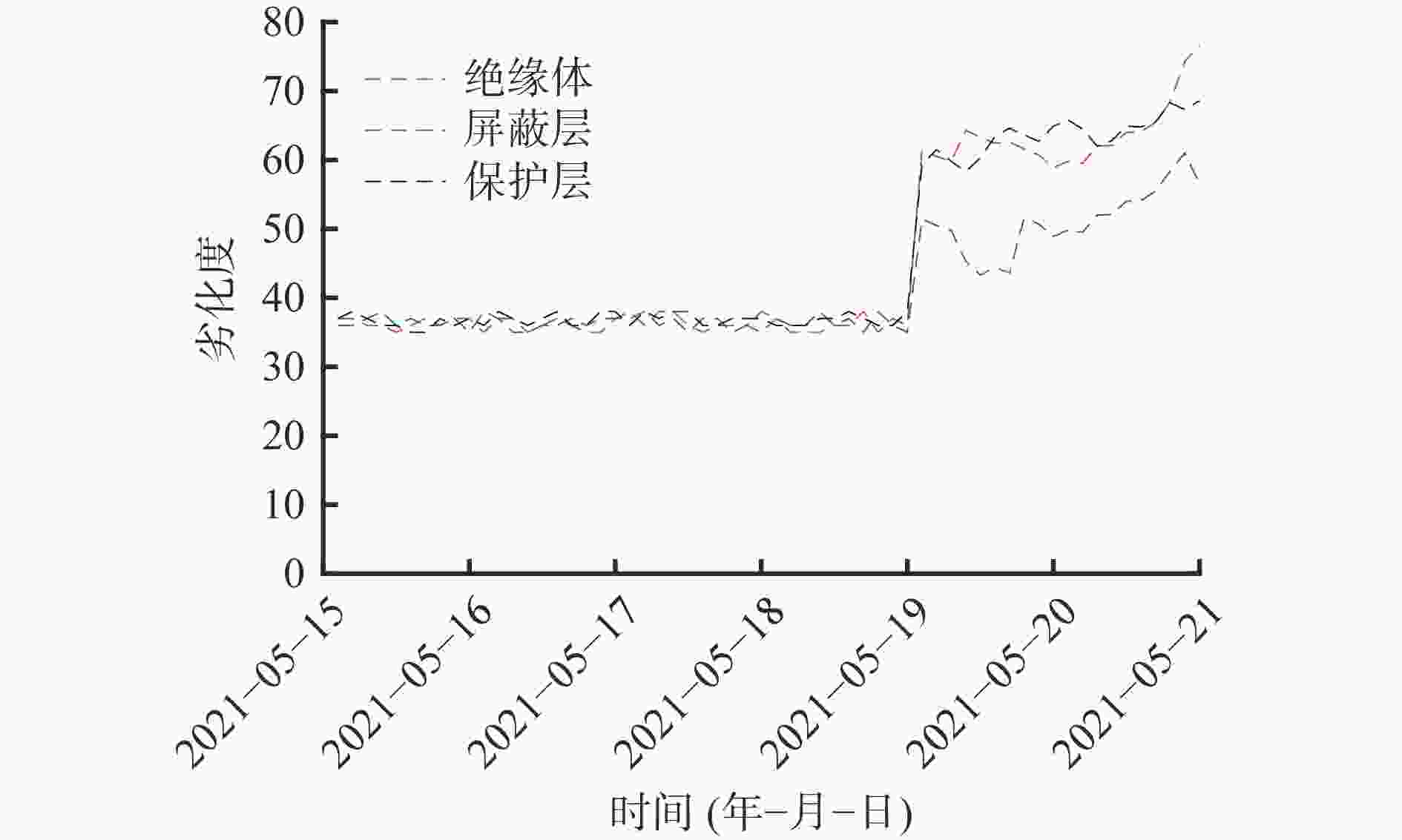

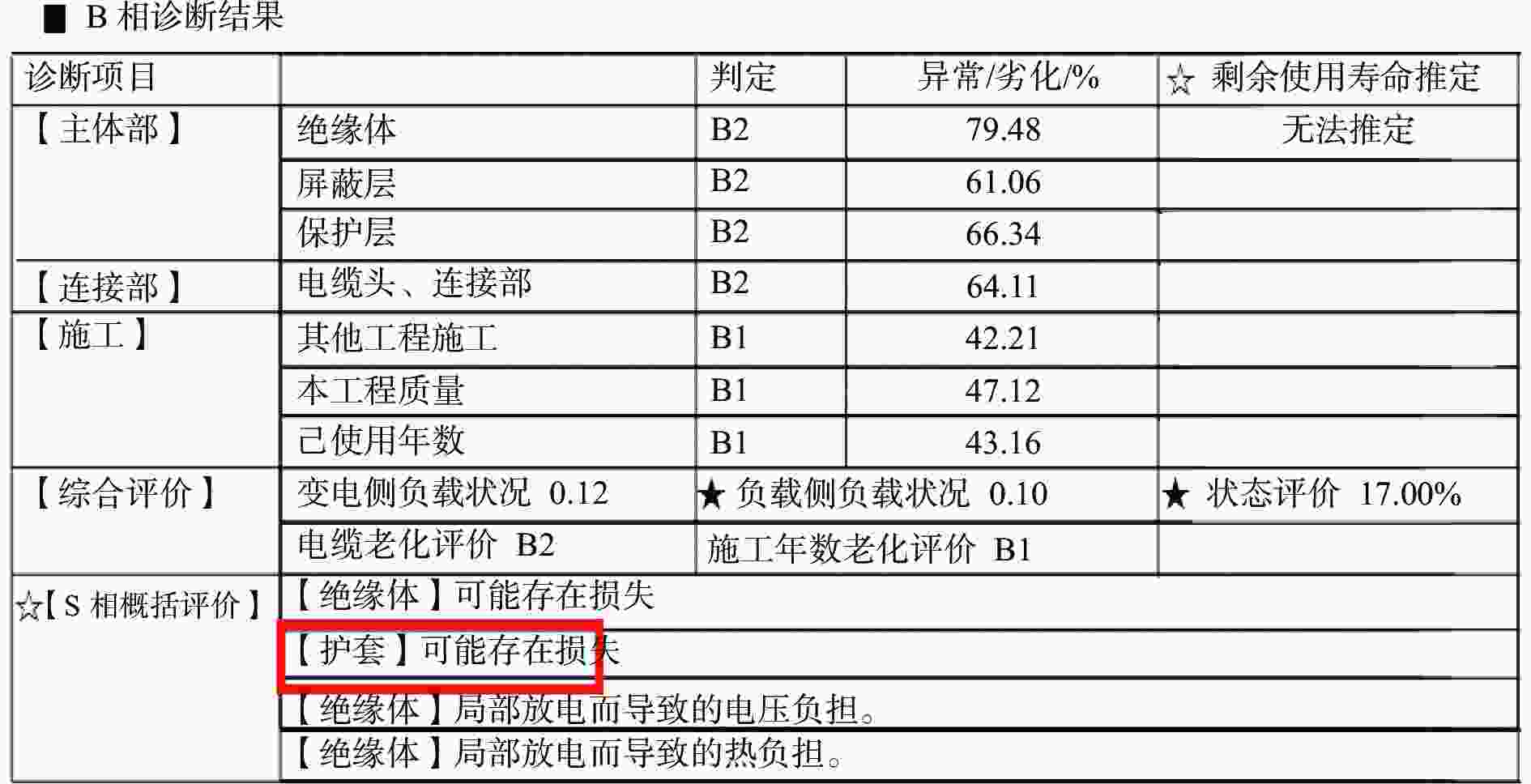

序号 H2 H3 H4 H5 H7 H8 H9 H10 时间 1 1.5 1.1 1.2 0.9 0.5 0.4 0.4 0.3 2021−05−18 2 1.4 1.3 1.4 1.1 0.5 0.4 0.3 0.4 2021−05−18 3 1.6 1.1 1.5 0.9 0.7 0.6 0.4 0.3 2021−05−18 4 1.5 1.2 1.4 1.3 0.6 0.3 0.3 0.2 2021−05−18 5 3.8 1.5 1.5 1.2 0.8 0.5 0.2 0.1 2021−05−19 6 2.4 1.4 1.4 1.3 0.6 0.5 0.4 0.3 2021−05−19 7 3.8 1.8 1.8 1.2 0.7 0.4 0.3 0.2 2021−05−19 8 3.4 2.1 1.4 1.0 0.9 0.5 0.5 0.3 2021−05−19 9 3.3 2.1 1.6 1.1 0.6 0.3 0.4 0.2 2021−05−19 -

[1] 雷志鹏,李蔚,何庆辉,等. 基于介电响应法的矿用电缆绝缘性能评估方法研究[J]. 工矿自动化,2023,49(1):46-55. doi: 10.13272/j.issn.1671-251x.18047LEI Zhipeng,LI Wei,HE Qinghui,et al. Study on evaluation method of insulation performance of mine cable based on dielectric response method[J]. Journal of Mine Automation,2023,49(1):46-55. doi: 10.13272/j.issn.1671-251x.18047 [2] 林晨,吝伶艳,雷志鹏,等. 基于PDC的多应力老化乙丙橡胶电缆绝缘状态评估[J]. 绝缘材料,2020,53(1):70-75. doi: 10.16790/j.cnki.1009-9239.im.2020.01.013LIN Chen,LIN Lingyan,LEI Zhipeng,et al. State evaluation of multi-stress aged EPR cable insulation based on PDC[J]. Insulating Materials,2020,53(1):70-75. doi: 10.16790/j.cnki.1009-9239.im.2020.01.013 [3] 李刚. 探讨电力电缆故障相关的原因与检测[J]. 中国设备工程,2022(9):169-171. doi: 10.3969/j.issn.1671-0711.2022.09.060LI Gang. Discussion on the causes and detection related to mining cable failure[J]. China Plant Engineering,2022(9):169-171. doi: 10.3969/j.issn.1671-0711.2022.09.060 [4] 袁燕岭,李世松,董杰,等. 电力电缆诊断检测技术综述[J]. 电测与仪表,2016,53(11):1-7. doi: 10.3969/j.issn.1001-1390.2016.11.001YUAN Yanling,LI Shisong,DONG Jie,et al. A review on diagnostic testing technique of electrical power cables[J]. Electrical Measurement & Instrumentation,2016,53(11):1-7. doi: 10.3969/j.issn.1001-1390.2016.11.001 [5] 袁易君,曹伟莹. 煤矿电缆故障检测仪的设计[J]. 煤矿机械,2009,30(10):131-133. doi: 10.3969/j.issn.1003-0794.2009.10.062YUAN Yijun,CAO Weiying. Design of coal mine cable failure instrumentation[J]. Coal Mine Machinery,2009,30(10):131-133. doi: 10.3969/j.issn.1003-0794.2009.10.062 [6] 张登奎. 基于局部放电的矿用XLPE电缆绝缘在线监测与定位技术研究[D]. 焦作:河南理工大学,2021.ZHANG Dengkui. Research on on-line monitoring and positioning technology of mining XLPE cable insulation based on particle discharge[D]. Jiaozuo:Henan Polytechnic University,2021. [7] 陆电. 矿井低压电缆绝缘参数在线检测的研究[D]. 西安:西安科技大学,2009.LU Dian. Research on the on-line monitoring of insulation parameter of mine low voltage cables[D]. Xi'an:Xi'an University of Science and Technology,2009. [8] 狄常馨,付周兴. 矿井低压电缆绝缘参数在线监测的研究[J]. 机电工程技术,2013,42(8):75-77,121. doi: 10.3969/j.issn.1009-9492.2013.08.019DI Changxin,FU Zhouxing. Research on on-line monitoring cable's insulation parameters of coal mine[J]. Mechanical & Electrical Engineering Technology,2013,42(8):75-77,121. doi: 10.3969/j.issn.1009-9492.2013.08.019 [9] 许丹. 新型井下照明微机综合保护装置研究[D]. 焦作:河南理工大学,2005.XU Dan. Research on new integrated protection device of underground lighting microcomputer[D]. Jiaozuo:Henan Polytechnic University,2005. [10] 陈琛,胡业林,赵世纯. 基于HDS的交联聚乙烯电缆健康诊断研究[J]. 佳木斯大学学报(自然科学版),2018,36(5):773-776. doi: 10.3969/j.issn.1008-1402.2018.05.030CHEN Chen,HU Yelin,ZHAO Shichun. Study on health diagnosis of crosslinked polyethylene cable based on HDS[J]. Journal of Jiamusi University(Natural Science Edition),2018,36(5):773-776. doi: 10.3969/j.issn.1008-1402.2018.05.030 [11] 赵世纯,凌标灿,朱希安,等. HDS电气设备带电状态诊断技术及应用[M]. 北京:电子工业出版社,2017:110-128.ZHAO Shichun,LING Biaocan,ZHU Xi'an,et al. Diagnosis technology and application of live state of HDS electrical equipment[M]. Beijing:Publishing House of Electronics Industry,2017:110-128. [12] HIROSHL K,GAO Bo. Method for diagnosing working condition and anomalous degradation of electric equipment:JP2004305694[P]. 2004-10-20. [13] TSUJIMOTO T,NAKADE M,YAGI Y,et al. Development of on-site diagnostic method for XLPE cable by harmonics in AC loss current[C]. The 7th International Conference on Properties and Applications of Dielectric Materials,Nagoya,2003:73-76. [14] 兰鹏,李忠华,周永勤. 交流电压对橡塑绝缘电缆现场绝缘测试分析[J]. 应用科技,2002(10):1-3. doi: 10.3969/j.issn.1009-671X.2002.10.001LAN Peng,LI Zhonghua,ZHOU Yongqin. Onsite AC testing and analysis of plastic insulated cables[J]. Applied Science and Technology,2002(10):1-3. doi: 10.3969/j.issn.1009-671X.2002.10.001 [15] 魏强. 基于谐波分量法XLPE电缆水树老化测试系统的研究[D]. 哈尔滨:哈尔滨理工大学,2004.WEI Qiang. Study on measuring system of water tree in XLPE cables based on measurement of harmonic distortion in loss current[D]. Harbin:Harbin University of Science and Technology,2004. [16] 任萍. 损耗因数及损耗电流谐波分量自动测试装置的研制[D]. 哈尔滨:哈尔滨理工大学,2014.REN Ping. The development of automatic test equipment for loss factor and harmonic component in loss current[D]. Harbin:Harbin University of Science and Technology,2014. [17] HIROSHL K,GAO Bo. Method for diagnosing abnormality in electric equipment:P2000-386603[P]. 2000-12-20. [18] ABD-EL-MALEK M,ABDELSALAM A K,HASSAN O E. Induction motor broken rotor bar fault location detection through envelope analysis of start-up current using Hilbert transform[J]. Mechanical Systems and Signal Processing,2017,93:332-350. doi: 10.1016/j.ymssp.2017.02.014 [19] 吴飞,王鹏程,杨康. 基于PCA−SSA−XGBoost的车辆驾驶性评估[J/OL]. 吉林大学学报(工学版):1-11[2023-06-17]. DOI: 10.13229/j.cnki.jdxbgxb.20230215.WU Fei,WANG Pengcheng,YANG Kang. Drivability evaluation model based on PCA-SSA-XGBoost[J/OL]. Journal of Jilin University(Engineering and Technology Edition):1-11[2023-06-17]. DOI: 10.13229/j.cnki.jdxbgxb.20230215. [20] 张天瑞,赵伟博,周福强,等. 一种基于改进极端梯度提升决策树的轴承故障诊断方法[J/OL]. 重庆师范大学学报(自然科学版):1-12[2023-06-17]. http://kns.cnki.net/kcms/detail/50.1165.n.20230621.1723.002.html.ZHANG Tianrui,ZHAO Weibo,ZHOU Fuqiang,et al. A bearing fault diagnosis method based on improved XGBoost[J]. Journal of Chongqing Normal University(Natural Science):1-12[2023-06-17]. http://kns.cnki.net/kcms/detail/50.1165.n.20230621.1723.002.html. [21] 郭培,陈波,高云超,等. 基于XGBOOST−PSO提高受端电网电压暂态稳定的发电机无功优化方法[J]. 电力系统保护与控制,2023,51(13):148-158. doi: 10.19783/j.cnki.pspc.221743GUO Pei,CHEN Bo,GAO Yunchao,et al. A generator reactive power optimization method based on XGBOOST-PSO to improve the voltage transient stability of a receiving terminal network[J]. Power System Protection and Control,2023,51(13):148-158. doi: 10.19783/j.cnki.pspc.221743 [22] 耿家豪,廖宇,马先超,等. 基于XGBoost的风力发电机故障诊断[J]. 通信与信息技术,2022(6):42-46.GENG Jiahao,LIAO Yu,MA Xianchao,et al. Fault diagnosis of wind turbine based on XGBoost[J]. Communication & Information Technology,2022(6):42-46. [23] 李琼林,李陈莹,庞博,等. 谐波对电力电缆损耗的影响分析与计算方法[J]. 电测与仪表,2015,52(23):34-42. doi: 10.3969/j.issn.1001-1390.2015.23.007LI Qionglin,LI Chenying,PANG Bo,et al. Impact analysis and calculation method of harmonic on power cable loss[J]. Electrical Measurement & Instrumentation,2015,52(23):34-42. doi: 10.3969/j.issn.1001-1390.2015.23.007 [24] 苗旺,陈平,任志刚,等. 电流谐波法在电力电缆状态检测诊断的应用进展[J]. 电力系统及其自动化学报,2021,33(3):73-80. doi: 10.19635/j.cnki.csu-epsa.000427MIAO Wang,CHEN Ping,REN Zhigang,et al. Research process in applications of current harmonic analysis to condition monitoring and diagnosis of power cable[J]. Proceedings of the CSU-EPSA,2021,33(3):73-80. doi: 10.19635/j.cnki.csu-epsa.000427 [25] 曹培,徐鹏,高凯,等. 基于边缘计算的电缆接头运行状态智能传感与监测[J]. 高压电器,2020,56(9):26-32. doi: 10.13296/j.1001-1609.hva.2020.09.004CAO Pei,XU Peng,GAO Kai,et al. Intelligent sensing and monitoring of cable joints' state based on edge computing[J]. High Voltage Apparatus,2020,56(9):26-32. doi: 10.13296/j.1001-1609.hva.2020.09.004 [26] 张伟霞. 10 kV电力电缆状态评估方法的研究[D]. 保定:华北电力大学,2013.ZHANG Weixia. Study on state assessment method of 10 kV power cable[D]. Baoding:North China Electric Power University,2013. -

下载:

下载: