| [1] |

王国法,范京道,徐亚军,等. 煤炭智能化开采关键技术创新进展与展望[J]. 工矿自动化,2018,44(2):5-12.WANG Guofa,FAN Jingdao,XU Yajun,et al. Innovation progress and prospect on key technologies of intelligent coal mining[J]. Industry and Mine Automation,2018,44(2):5-12.

|

| [2] |

王国法,刘峰,孟祥军,等. 煤矿智能化(初级阶段)研究与实践[J]. 煤炭科学技术,2019,47(8):1-36.WANG Guofa,LIU Feng,MENG Xiangjun,et al. Research and practice on intelligent coal mine construction(primary stage)[J]. Coal Science and Technology,2019,47(8):1-36.

|

| [3] |

王国法,庞义辉,任怀伟. 煤矿智能化开采模式与技术路径[J]. 采矿与岩层控制工程学报,2020,2(1):5-19.WANG Guofa,PANG Yihui,REN Huaiwei. Intelligent coal mining pattern and technological path[J]. Journal of Mining and Strata Control Engineering,2020,2(1):5-19.

|

| [4] |

王国法,刘峰,庞义辉,等. 煤矿智能化−煤炭工业高质量发展的核心技术支撑[J]. 煤炭学报,2019,44(2):349-357.WANG Guofa,LIU Feng,PANG Yihui,et al. Coal mine intellectualization:the core technology of high quality development[J]. Journal of China Coal Society,2019,44(2):349-357.

|

| [5] |

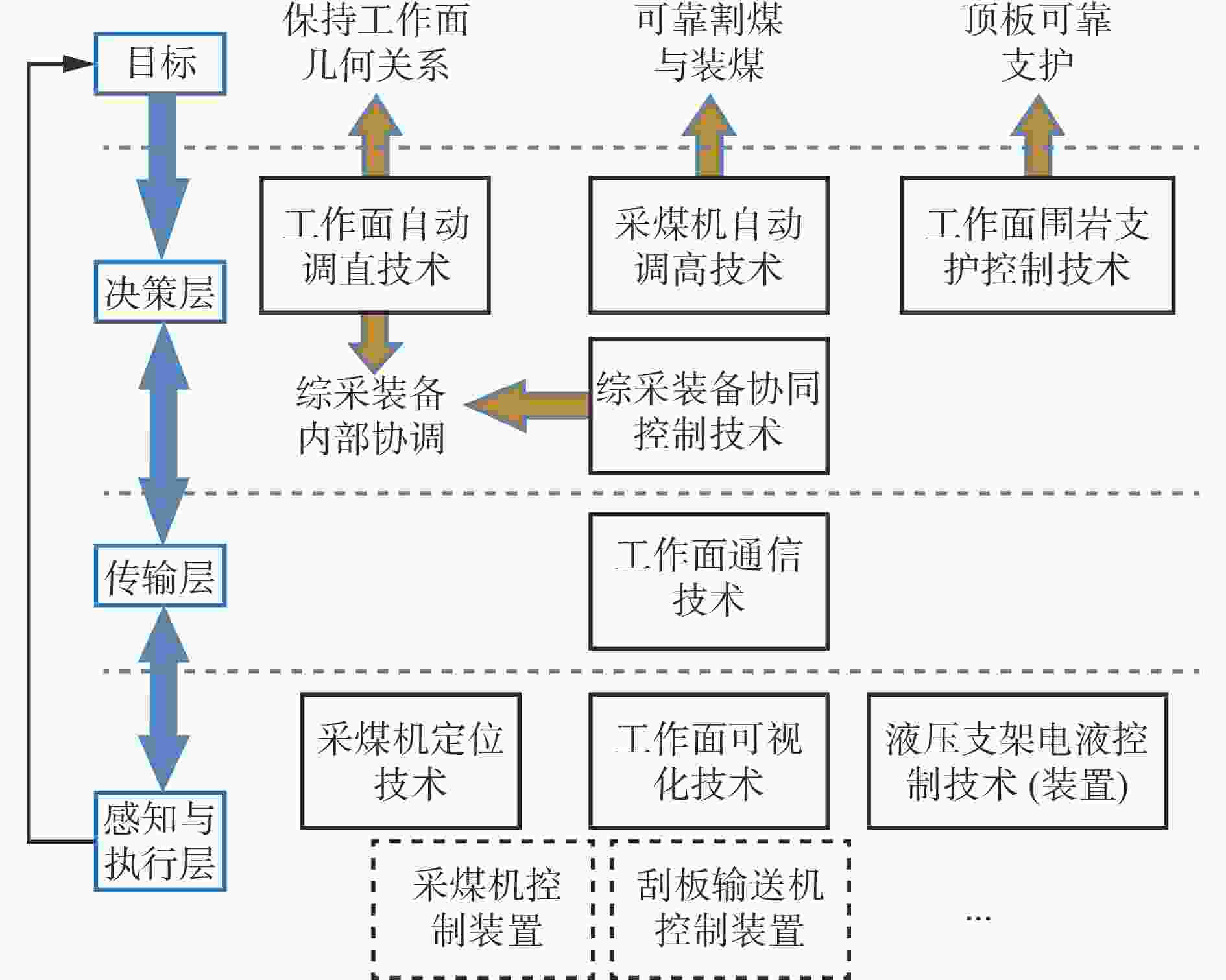

葛世荣. 煤矿智采工作面概念及系统架构研究[J]. 工矿自动化,2020,46(4):1-9.GE Shirong. Research on concept and system architecture of smart mining workface in coal mine[J]. Industry and Mine Automation,2020,46(4):1-9.

|

| [6] |

葛世荣,郝尚清,张世洪,等. 我国智能化采煤技术现状及待突破关键技术[J]. 煤炭科学技术,2020,48(7):28-46.GE Shirong,HAO Shangqing,ZHANG Shihong,et al. Status of intelligent coal mining technology and potential key technologies in China[J]. Coal Science and Technology,2020,48(7):28-46.

|

| [7] |

T/CCS 002−2020 智能化采煤工作面分类、分级技术条件与评价指标体系[S].T/CCS 002-2020 Specification, classification and grading evaluation index for longwall face of smart coal mine[S].

|

| [8] |

王国法,徐亚军,孟祥军,等. 智能化采煤工作面分类、分级评价指标体系[J]. 煤炭学报,2020,45(9):3033-3044.WANG Guofa,XU Yajun,MENG Xiangjun,et al. Specification,classification and grading evaluation index for smart longwall mining face[J]. Journal of China Coal Society,2020,45(9):3033-3044.

|

| [9] |

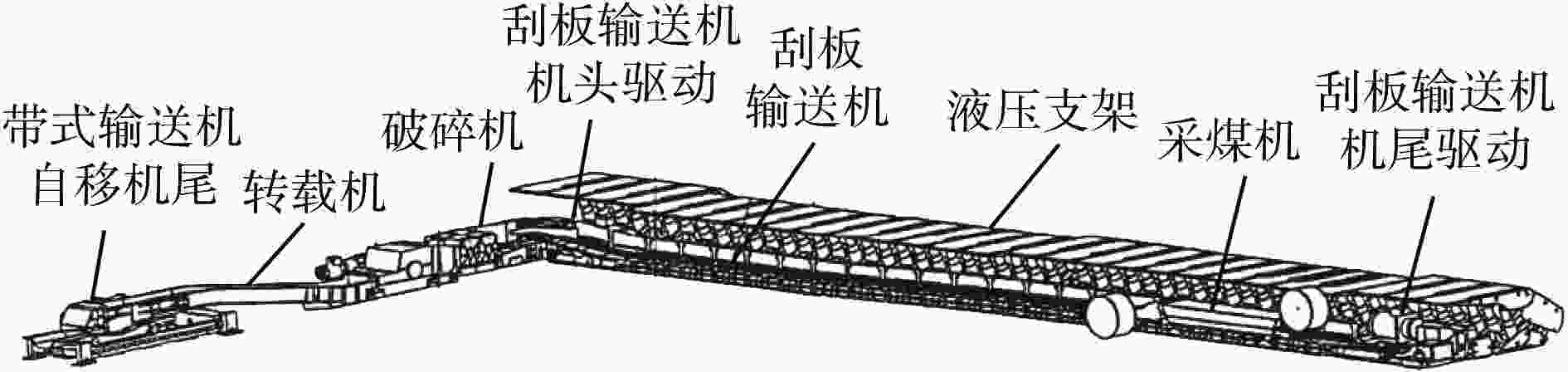

李首滨. 智能化开采研究进展与发展趋势[J]. 煤炭科学技术,2019,47(10):102-110.LI Shoubin. Progress and development trend of intelligent mining technology[J]. Coal Science and Technology,2019,47(10):102-110.

|

| [10] |

伍小杰,于月森,彭利明,等. 液压支架电液控技术的现状及展望[J]. 煤炭科学技术,2009,37(1):25-29. doi: 10.13199/j.cst.2009.01.59.wuxj.007WU Xiaojie,YU Yuesen,PENG Liming,et al. Present status and outlook of electric and hydraulic control technology for hydraulic powered support[J]. Coal Science and Technology,2009,37(1):25-29. doi: 10.13199/j.cst.2009.01.59.wuxj.007

|

| [11] |

金静飞,王凯. 综采装备协同控制系统的设计[J]. 煤矿机械,2014,35(8):214-216.JIN Jingfei,WANG Kai. Design of coordinated control system of fully mechanized equipment[J]. Coal Mine Machinery,2014,35(8):214-216.

|

| [12] |

CZWALINNA J, KUBIK J, BIGBY D N, et al. New mechanization and automation of longwall and drivage equipment[R]. Luxembourg: Research Fund for Coal and Steel, 2011.

|

| [13] |

Interconnection of landmark compliant longwall mining equipment-shearer communication specification for OEM accessible inertial sensor data[R]. CSIRO Exploration and Mining Report, 2005.

|

| [14] |

黄曾华. 煤矿综采工作面视频系统的应用研究[J]. 煤矿机电,2013(4):1-5.HUANG Zenghua. Application research on video system at fully mechanized mining field[J]. Colliery Mechanical & Electrical Technology,2013(4):1-5.

|

| [15] |

葛世荣,苏忠水,李昂,等. 基于地理信息系统(GIS)的采煤机定位定姿技术研究[J]. 煤炭学报,2015,40(11):2503-2508.GE Shirong,SU Zhongshui,LI Ang,et al. Study on the positioning and orientation of a shearer based on geographic information system[J]. Journal of China Coal Society,2015,40(11):2503-2508.

|

| [16] |

REID D C, HAINSWORTH D W, RALSTON J C, et al. Longwall shearer guidance using inertial navigation (ACARP project C9015)[R]. CSIRO, Exploration and Mining Report 832F, 2001.

|

| [17] |

王世佳,王世博,张博渊,等. 采煤机惯性导航定位动态零速修正技术[J]. 煤炭学报,2018,43(2):578-583.WANG Shijia,WANG Shibo,ZHANG Boyuan,et al. Dynamic zero-velocity update technology to shearer inertial navigation positioning[J]. Journal of China Coal Society,2018,43(2):578-583.

|

| [18] |

孔维. 基于煤层地理信息系统的采煤机截割路径规划方法[D]. 徐州: 中国矿业大学, 2019.KONG Wei. Cutting path planning method of shearer based on coal seam geographic information system[D]. Xuzhou: China University of Mining and Technology, 2019.

|

| [19] |

LI Wei,LUO Chengming,YANG Hai,et al. Memory cutting of adjacent coal seams based on a hidden Markov model[J]. Arabian Jouranl of Geosciences,2014,7(12):5051-5060. doi: 10.1007/s12517-013-1145-5

|

| [20] |

WANG Shibo, WANG Shijia. Longwall mining automation horizon control: coal seam gradient identification using piecewise linear fitting[J/OL]. International Journal of Mining Science and Technology, 2022[2022-05-15]. https://doi.org/10.1016/j.ijmst.2022.02.003.

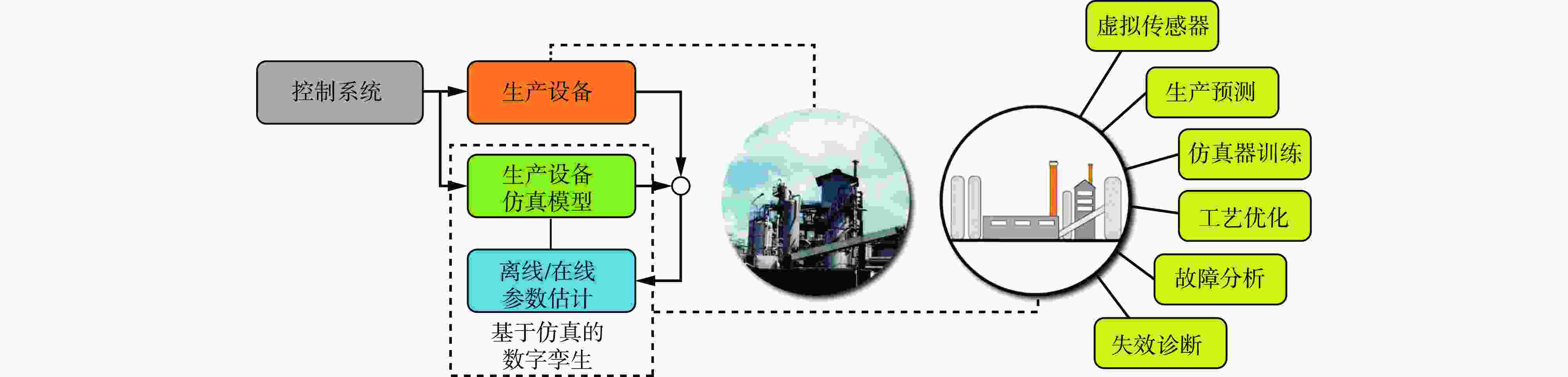

|

| [21] |

王世博,何亚,王世佳,等. 刮板输送机调直方法与试验研究[J]. 煤炭学报,2017,42(11):3044-3050.WANG Shibo,HE Ya,WANG Shijia,et al. Study on the alignment method and experiment of scraper conveyor[J]. Journal of China Coal Society,2017,42(11):3044-3050.

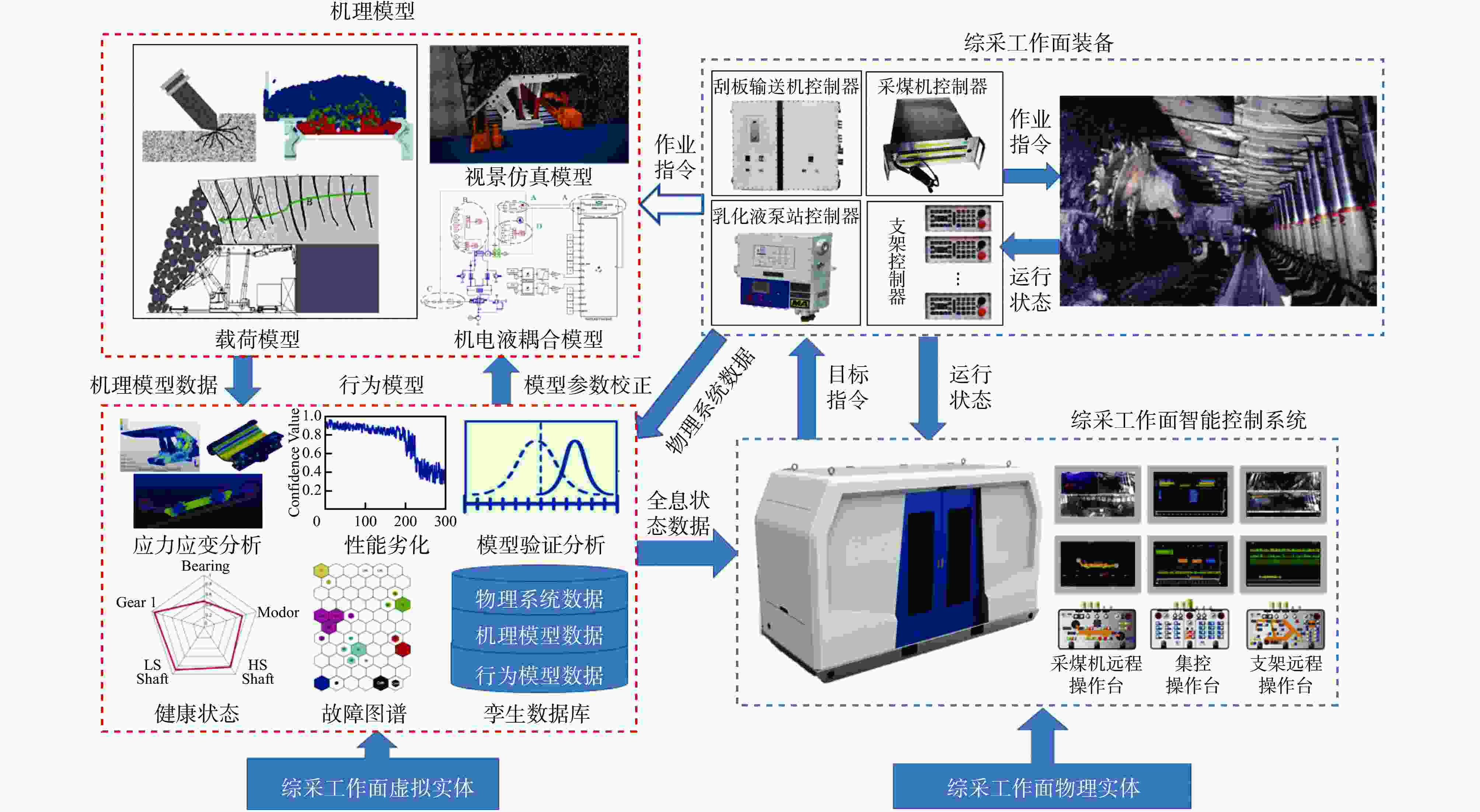

|

| [22] |

李森. 基于惯性导航的工作面直线度测控与定位技术[J]. 煤炭科学技术,2019,47(8):169-174.LI Sen. Measurement & control and localisation for fully-mechanized working face alignment based on inertial navigation[J]. Coal Science and Technology,2019,47(8):169-174.

|

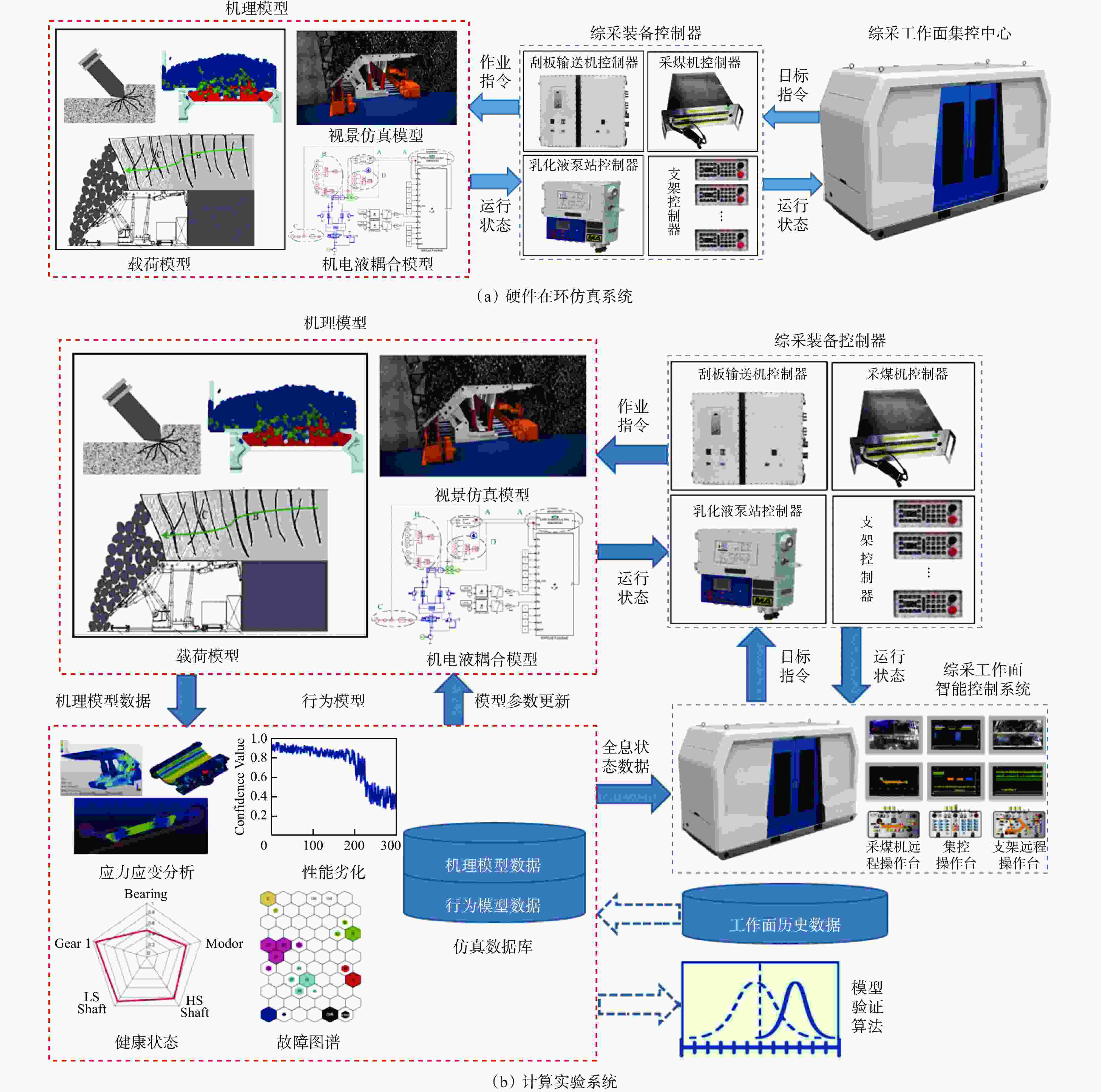

| [23] |

侯刚. 互联网+液压支架智能耦合控制系统设计与实现[J]. 煤矿开采,2017,22(1):105-108.HOU Gang. Intelligent coupling control system design and implementation of Internet and hydraulic support[J]. Coal Mining Technology,2017,22(1):105-108.

|

| [24] |

TRUEMAN R,LYMAN G,COCKER A. Longwall roof control through a fundamental understanding of shield-strata interaction[J]. International Journal of Rock Mechanics and Mining Sciences,2009,46:371-380. doi: 10.1016/j.ijrmms.2008.07.003

|

| [25] |

王世博,葛世荣,王世佳,等. 长壁综采工作面无人自主开采发展路径与挑战[J]. 煤炭科学技术,2022,50(2):231-243.WANG Shibo,GE Shirong,WANG Shijia,et al. Development and chanllege of unmanned autonomous longwall fully-mechanized coal mining face[J]. Coal Science and Technology,2022,50(2):231-243.

|

| [26] |

黄曾华,王峰,张守祥. 智能化采煤系统架构及关键技术研究[J]. 煤炭学报,2020,45(6):1959-1972.HUANG Zenghua,WANG Feng,ZHANG Shouxiang. Research on the architecture and key technologies of intelligent coal mining system[J]. Journal of China Coal Society,2020,45(6):1959-1972.

|

| [27] |

ZHAO Shuanfeng,WANG Pengfei,LI Shijun. Study on the fault diagnosis method of scraper conveyor gear under time-varying load condition[J]. Applied Sciences,2020,10(15):5053. doi: 10.3390/app10155053

|

| [28] |

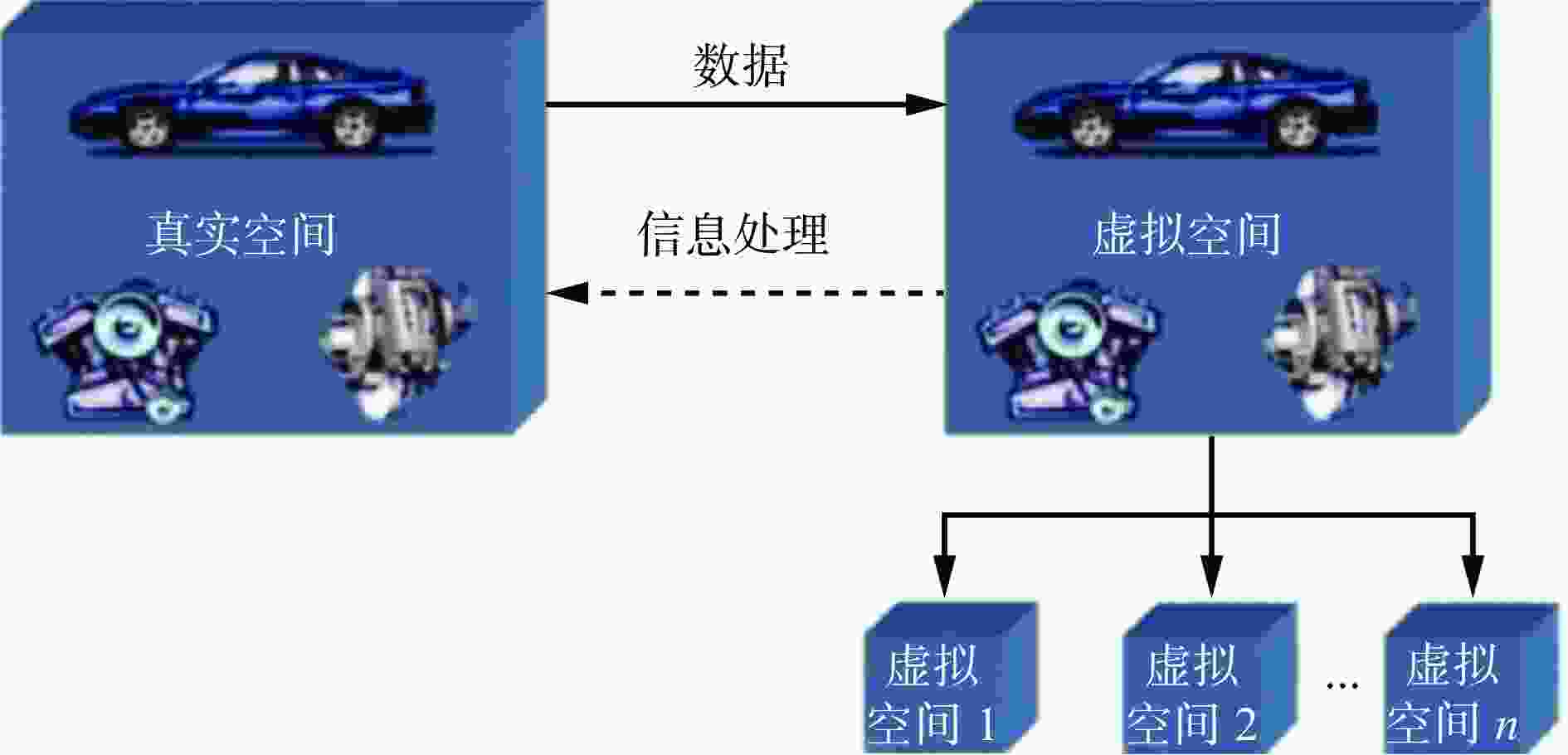

GELERNTER D. Mirror worlds[M]. Oxford: Oxford University Press, 1991.

|

| [29] |

GRIEVES M. Product lifecycle management:the new paradigm for enterprises[J]. International Journal of Product Development,2005,2(1/2):71-84. doi: 10.1504/IJPD.2005.006669

|

| [30] |

方志刚. 复杂装备系统数字孪生[M]. 北京: 机械工业出版社, 2021.FANG Zhigang. Digital twin of complex equipment system[M]. Beijing: China Machine Press, 2021.

|

| [31] |

GLAESSGEN E H, STARGEL D S. The digital twin paradigm for future NASA and US air force vehicles[C]//The 53rd AIAA/ASME/ASCE/AHS/ASC Structural Dynamics and Materials Conference: Special Session on the Digital Twin, Honolulu, 2012.

|

| [32] |

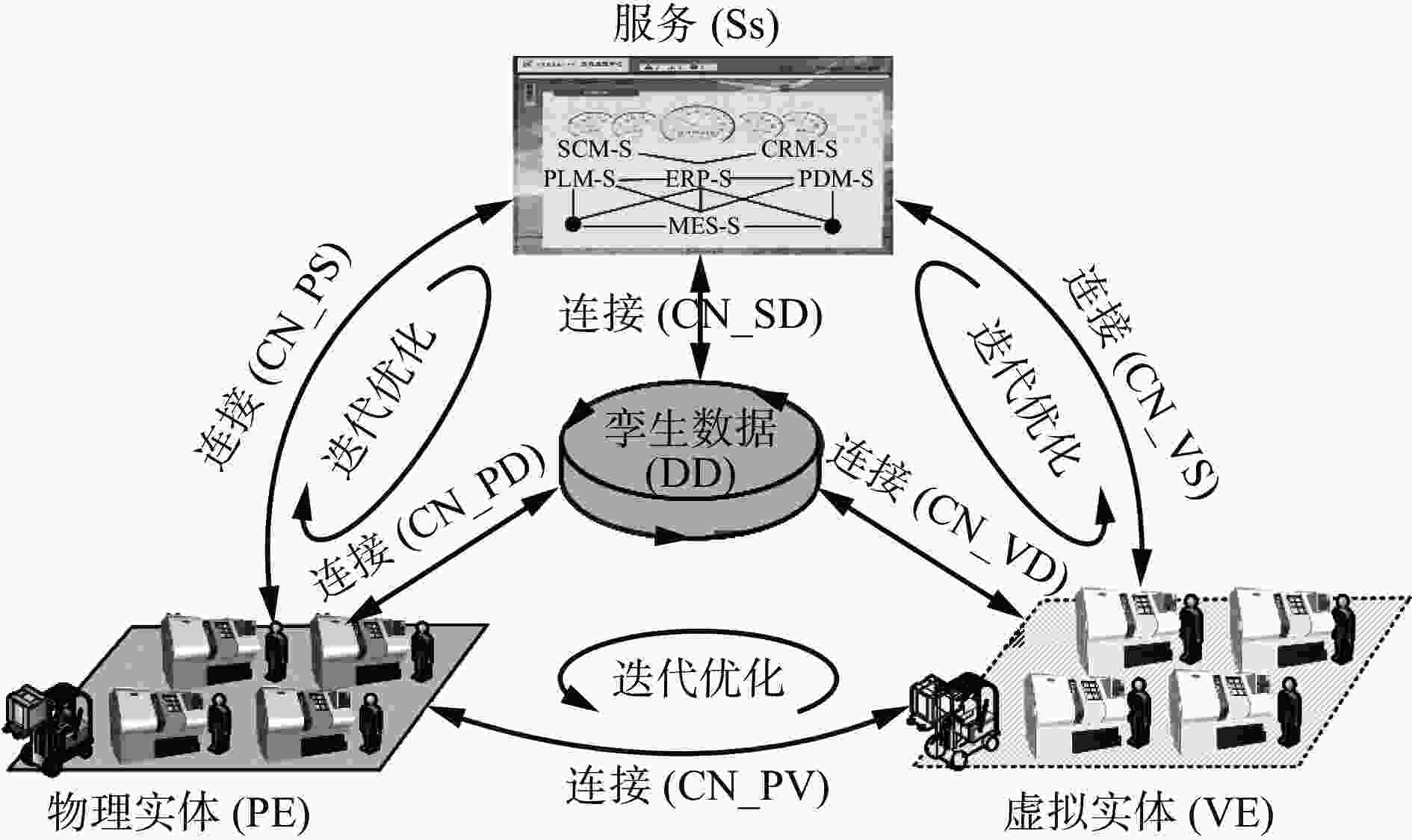

陶飞,刘蔚然,刘检华,等. 数字孪生及其应用探索[J]. 计算机集成制造系统,2018,24(1):1-18.TAO Fei,LIU Weiran,LIU Jianhua,et al. Digital twin and its potential application exploration[J]. Computer Integrated Manufacturing Systems,2018,24(1):1-18.

|

| [33] |

刘亚威. 面向飞行器结构健康管理的数字孪生及应用研究综述[J]. 测控技术,2022,41(1):1-10. doi: 10.19708/j.ckjs.2021.03.220LIU Yawei. Review on digital twin and its application research for aircraft structure health management[J]. Measurement & Control Technology,2022,41(1):1-10. doi: 10.19708/j.ckjs.2021.03.220

|

| [34] |

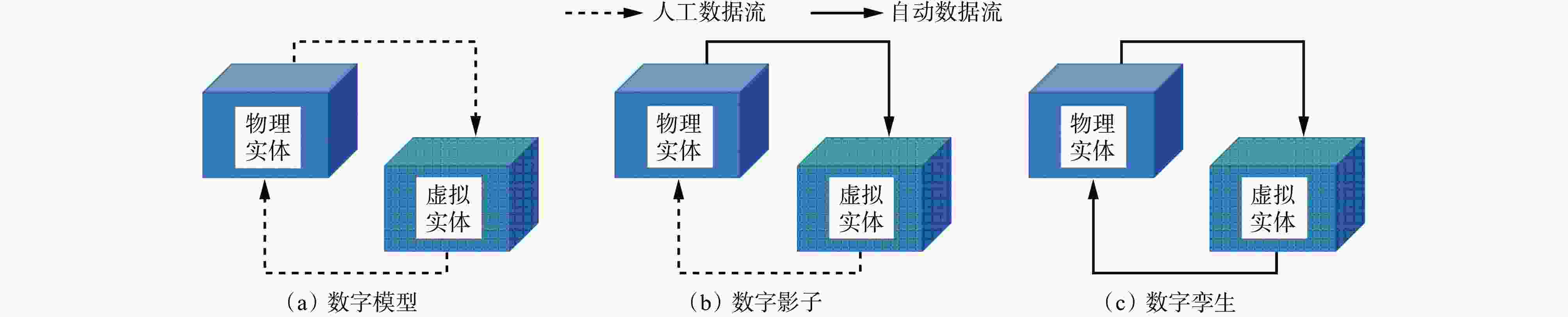

KRITZINGER W,KARNER M,TRAAR G,et al. Digital twin in manufacturing:a categorical literature review and classification[J]. IFAV PapersOnLine,2018,51(11):1016-1022. doi: 10.1016/j.ifacol.2018.08.474

|

| [35] |

蔡武,陈果,朱志敏,等. 基于3D Max和Virtools的矿井虚拟仿真系统设计[J]. 煤炭工程,2011(1):111-113,116.CAI Wu,CHEN Guo,ZHU Zhimin,et al. Design of mine virtual simulation system based on 3D Max and Virtools[J]. Coal Engineering,2011(1):111-113,116.

|

| [36] |

沙同震. 矿井虚拟仿真系统设计中3DMax和Virtools的应用[J]. 煤炭技术,2014,33(1):183-185.SHA Tongzhen. Application of 3DMax and Virtools in design of mine virtual simulation system[J]. Coal Technology,2014,33(1):183-185.

|

| [37] |

王鹏,宿国瑞,贾宝山,等. 基于VR技术的虚拟矿井仿真平台建设[J]. 煤矿安全,2020,51(1):122-125.WANG Peng,SU Guorui,JIA Baoshan,et al. Construction of virtual mine simulation platform based on VR technology[J]. Safety in Coal Mines,2020,51(1):122-125.

|

| [38] |

王学文,谢嘉成,郝尚清,等. 智能化综采工作面实时虚拟监测方法与关键技术[J]. 煤炭学报,2020,45(6):1984-1996.WANG Xuewen,XIE Jiacheng,HAO Shangqing,et al. Key technologies of real-time virtual monitoring method for an intelligent fully mechanized coal-mining face[J]. Journal of China Coal Society,2020,45(6):1984-1996.

|

| [39] |

BRANDTSTATEDER H, LUDWIG C, HÜBNER L, et al. Digital twins for large electric drive trains[C]//Petroleum and Chemical Industry Conference Europe, Antwerp, 2018: 1-5.

|

| [40] |

ZHANG Yong, BAI Jiangpo, LYU Kehong, et al. Key problems of virtual testability demonstration based on digital twin technology[C]//The 11th International Conference on Prognostics and System Health Management, Jinan, 2020.

|

| [41] |

WANG Jinjiang,YE Lunkuan,GAO R X,et al. Digital twin for rotating machinery fault diagnosis in smart manufacuturing[J]. International Journal of Production Research,2019,57(11/12):3920-3934.

|

| [42] |

FRAZZON E M,ALBRECHT A,HURTADO P A. Simulation-based optimization for the integrated scheduling of production and logistic systems[J]. IFAC-PapersOnline,2016,49(12):1050-1055. doi: 10.1016/j.ifacol.2016.07.581

|

| [43] |

JAIN S,CHOONG N F,AYE K M. Virtual factory:an integrated approach to manufacturing systems modeling[J]. International Journal of Operations & Production Management,2001,21(5/6):594-608.

|

| [44] |

孙学民,刘世民,申兴旺,等. 数字孪生驱动的高精密产品智能化装配方法[J]. 计算机集成制造系统,2022,28(6):1704-1716.SUN Xuemin,LIU Shimin,SHEN Xingwang,et al. Digital twin-driven intelligent assembly method for high precision products[J]. Computer Integrated Manufacturing Systems,2022,28(6):1704-1716.

|

| [45] |

GUO Jinyan,YANG Zhaojun,CHEN Chuanhai,et al. Real-time prediction of remaining useful life and preventive maintenance strategy based on digital twin[J]. Journal of Computing and Information Science in Engineering,2021,21:031003-1. doi: 10.1115/1.4049153

|

| [46] |

LEE J,NI Jun,DJURDJANOVIC D,et al. Intelligent prognostics tools and e-maintenance[J]. Computers in Industry,2006,57(6):476-489. doi: 10.1016/j.compind.2006.02.014

|

| [47] |

TAO Fei,ZHANG Meng,LIU Yushan,et al. Digital twin driven prognostics and health management for complex equipment[J]. CIRP Annals-Manufacturing Technology,2018,67(1):169-172. doi: 10.1016/j.cirp.2018.04.055

|

| [48] |

ZHUANG Cunbo,LIU Jianhua,XIONG Hui. Digital twin-based smart production management and control framework for the complex product assembly shop-floor[J]. The International Journal of Advanced Manufacture Technology,2018,96(2):1149-1163.

|

| [49] |

SHAO Guodong,HELU M. Framework for a digital twin in manufacturing:scope and requirements[J]. Manufacturing Letters,2020,24:105-107. doi: 10.1016/j.mfglet.2020.04.004

|

| [50] |

REED S,LÖFSTRAND M,ANDREWS J. Modelling cycle for simulation digital twins[J]. Manufacturing Letters,2021,28:54-58. doi: 10.1016/j.mfglet.2021.04.004

|

| [51] |

陶飞,马昕,胡天亮,等. 数字孪生标准体系[J]. 计算机集成制造系统,2019,25(10):2405-2418. doi: 10.13196/j.cims.2019.10.001TAO Fei,MA Xin,HU Tianliang,et al. Research on digital twin standard system[J]. Computer Integrated Manufacturing Systems,2019,25(10):2405-2418. doi: 10.13196/j.cims.2019.10.001

|

| [52] |

陶飞,刘蔚然,张萌,等. 数字孪生五维模型及十大领域应用[J]. 计算机集成制造系统,2019,25(1):1-18.TAO Fei,LIU Weiran,ZHANG Meng,et al. Five-dimension digital twin model and its ten applications[J]. Computer Integrated Manufacturing Systems,2019,25(1):1-18.

|

| [53] |

张霖,陆涵. 从建模仿真看数字孪生[J]. 系统仿真学报,2021,33(5):995-1007. doi: 10.16182/j.issn1004731x.joss.21-0262ZHANG Lin,LU Han. Discussing digital twin from of modeling and simulation[J]. Journal of System Simulation,2021,33(5):995-1007. doi: 10.16182/j.issn1004731x.joss.21-0262

|

| [54] |

TAO Fei, ZHANG Meng, NEE A Y C. Digital twin driven smart manufacturing[M/OL]. [2022-05-16]. https://www.sciencedirect.com/book/9780128176306/digital-twin-driven-smart-manufacturing#book-description.

|

| [55] |

STOJANOVIC N, MILENOVIC D. Data-driven digital twin approach for process optimization: an industry use case[C]//IEEE International Conference on Big Data, Seattle, 2018: 4202-4211.

|

| [56] |

CORADDU A,ONETO L,BALDI F,et al. Data-driven ship digital twin for estimating the speed loss caused by the marine fouling[J]. Ocean Engineering,2019,186:106063. doi: 10.1016/j.oceaneng.2019.05.045

|

| [57] |

PAN Yue,ZHANG Limao. A BIM-data mining integrated digital twin framework for advanced project management[J]. Automation in Construction,2021,124:103564. doi: 10.1016/j.autcon.2021.103564

|

| [58] |

WRIGHT L,DAVIDSON S. How to tell the difference between a model and a digital twin[J]. Advanced Modeling and Simulation in Engineering Sciences,2020,7(1):13. doi: 10.1186/s40323-020-00147-4

|

| [59] |

MARTÍNEZ G S, SIERLA S, KARHELA T, et al. Automatic generation of simulation-based digital twin of an industrial process plant[C]//The 44th Annual Conference of the IEEE Industrial Electronics Society, Washington, 2018.

|

| [60] |

葛世荣,张帆,王世博,等. 数字孪生智采工作面技术架构研究[J]. 煤炭学报,2020,45(6):1925-1936. doi: 10.13225/j.cnki.jccs.ZN20.0327GE Shirong,ZHNAG Fan,WANG Shibo,et al. Digital twin for smart coal mining workface:technological frame and construction[J]. Journal of China Coal Society,2020,45(6):1925-1936. doi: 10.13225/j.cnki.jccs.ZN20.0327

|

| [61] |

丁恩杰,俞啸,夏冰,等. 矿山信息化发展及以数字孪生为核心的智慧矿山关键技术[J]. 煤炭学报,2022,47(1):564-578. doi: 10.13225/j.cnki.jccs.yg21.1930DING Enjie,YU Xiao,XIA Bing,et al. Development of mine informatization and key technologies of intelligent mines[J]. Journal of China Coal Society,2022,47(1):564-578. doi: 10.13225/j.cnki.jccs.yg21.1930

|

| [62] |

谢嘉成,王学文,杨兆建. 基于数字孪生的综采工作面生产系统设计与运行模式[J]. 计算机集成制造系统,2019,25(6):1381-1391. doi: 10.13196/j.cims.2019.06.007XIE Jiacheng,WANG Xuewen,YANG Zhaojian. Design and operation mode of production system of fully mechanized coal mining face based on digital twin theory[J]. Computer Integrated Manufacturing Systems,2019,25(6):1381-1391. doi: 10.13196/j.cims.2019.06.007

|

| [63] |

张旭辉,张超,杨文娟,等. 数字孪生驱动采掘工作面远程控制技术分析及发展趋势[J]. 智能矿山,2020,1(1):112-124.ZHANG Xuhui,ZHANG Chao,YANG Wenjuan,et al. Current status analysis and development trend of remote control technology of digital twin-driven mining face[J]. Journal of Intelligent Mine,2020,1(1):112-124.

|

| [64] |

张旭辉,张超,王妙云,等. 数字孪生驱动的悬臂式掘进机虚拟操控技术[J]. 计算机集成制造系统,2021,27(6):1617-1628. doi: 10.13196/j.cims.2021.06.008ZHANG Xuhui,ZHANG Chao,WANG Miaoyun,et al. Digital twin-driven virtual control technology of cantilever roadheader[J]. Computer Integrated Manufacturing Systems,2021,27(6):1617-1628. doi: 10.13196/j.cims.2021.06.008

|

| [65] |

丁华,杨亮亮,杨兆建,等. 数字孪生与深度学习融合驱动的采煤机健康状态预测[J]. 中国机械工程,2020,31(7):815-823. doi: 10.3969/j.issn.1004-132X.2020.07.007DING Hua,YANG Liangliang,YANG Zhaojian,et al. Health prediction of shearers driven by digital twin and deep learning[J]. China Mechanical Engineering,2020,31(7):815-823. doi: 10.3969/j.issn.1004-132X.2020.07.007

|

| [66] |

王世博,葛世荣,邹文才,等. 综采工作面半实物仿真系统技术架构[J]. 智能矿山,2020,1(1):125-131.WANG Shibo,GE Shirong,ZOU Wencai,et al. Hardware-in-the-loop simulation system of longwall mining face:technological frame and construction[J]. Journal of Intelligent Mine,2020,1(1):125-131.

|

| [67] |

王飞跃,刘德荣,熊刚,等. 复杂系统的平行控制理论及应用[J]. 复杂系统与复杂性科学,2012,9(3):1-12. doi: 10.3969/j.issn.1672-3813.2012.03.001WANG Feiyue,LIU Derong,XIONG Gang,et al. Parallel control theory of complex systems and applications[J]. Complex Systems and Complexity Science,2012,9(3):1-12. doi: 10.3969/j.issn.1672-3813.2012.03.001

|

| [68] |

SCHLUSE M, ROSSMANN J. From simulation to experimentable digital twins: simulation-based development and operation of complex technical systems[C]//IEEE International Symposium on Systems Engineering, Edinburgh, 2016.

|

下载:

下载: