0 引言

国家煤炭工业“十四五”规划指出,煤炭仍是我国的主体能源[1]。煤炭开采过程中岩体力学性状受断层与节理的尺度与角度等地质构造因素影响[2-3],其破坏过程中的裂纹扩展与力学行为具有非均匀性特征。研究大尺度裂纹岩体破坏过程中的损伤特性与能量转移耗散规律对地质构造影响下的巷道支护设计、矿压控制等具有一定理论指导意义。

众多专家学者对单条和多条预制裂纹岩样的强度与裂纹扩展规律进行了研究,揭示了新生裂纹萌生、扩展与贯通机制[4-6];同时,对岩样单轴和三轴压缩条件下的能量变化规律、煤岩组合体加卸载过程中的能量演化机制及破坏规律、非贯通节理岩样的能量转化特征等进行了系统研究,探讨了岩样破坏的能量驱动机制[7-11]。

上述研究主要针对小尺度预制裂纹岩样,而在实际工程实践中岩体地质构造尺度与产状均较大,相较于完整岩体,其受采动影响后的破碎程度与动力灾害发生可能性均较大。因此,本文以预制裂纹岩样为研究对象,开展大尺度预制裂纹岩样的单轴压缩试验,研究岩样力学损伤特性及应力-应变全过程的总应变能、弹性应变能、耗散应变能、峰后释放应变能与盈余应变能随预制裂纹倾角变化的演化规律。

1 试验方案

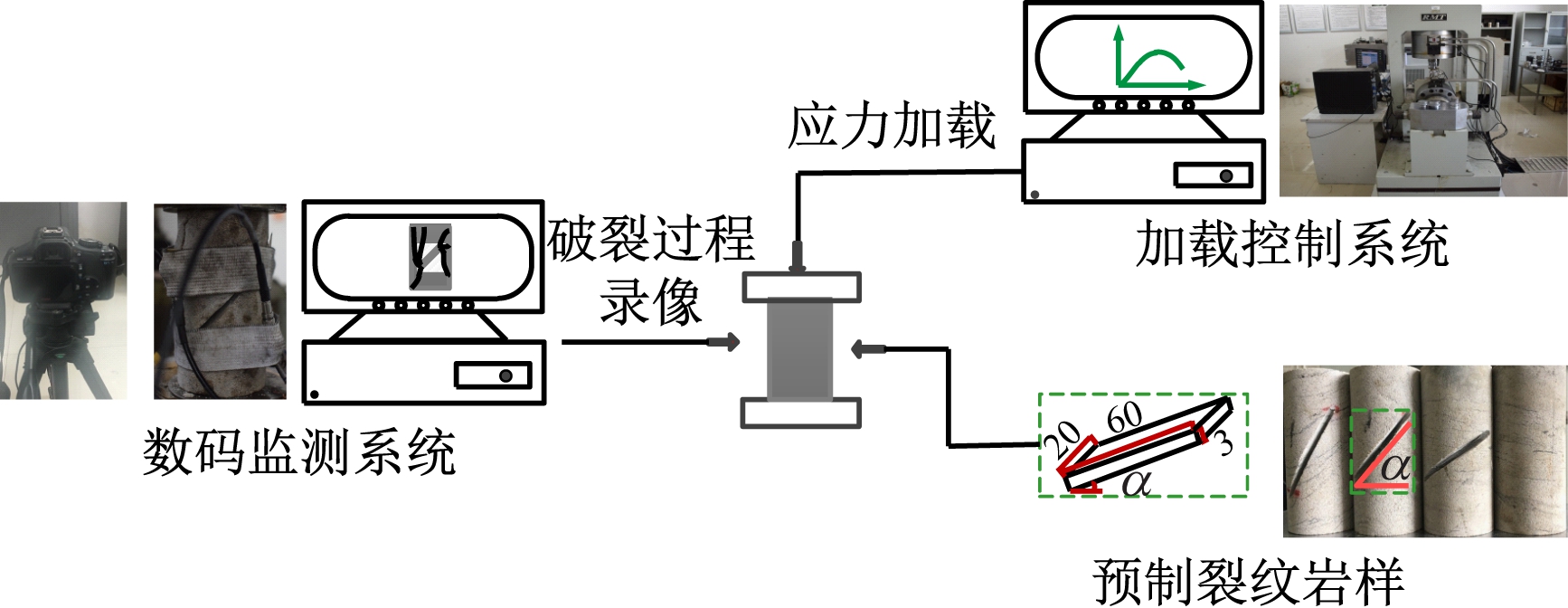

试验所用岩石取自淮南矿业(集团)有限责任公司潘北煤矿细砂岩层,利用岩石取芯机、切石机和磨平机将现场取回的大尺度岩块加工成直径为50 mm、高度为100 mm的标准圆柱体岩样,要求岩样两端面不平整度符合GB/T 23561.7—2009《煤和岩石物理力学性质测定方法 第7部分:单轴抗压强度测定及软化系数计算方法》要求。试验共制备12个标准岩样,分为4组,每组3个岩样。其中1组为完整岩样,3个岩样的标号为R1—R3;其余3组分别是裂纹倾角(裂纹与岩样端面间的夹角)为30,45,60°的预制裂纹岩样,倾角为30°的第1个岩样标号为30°-R1,其余岩样标号依此类推。岩样的裂纹由金刚石电动切割机切割而成,长度为60 mm,宽度为3 mm,深度为20 mm。

加载控制系统采用RMT-150B高精度刚性伺服控制压力机,可实现常规单轴和三轴压缩试验,且能够自动采集和处理试验数据,并显示应力-应变曲线等。试验采用应力加载,加载速率为0.5 kN/s,加载至岩样完全破坏。数码监测系统采用Nikon摄像机捕捉岩样加载过程中的破裂形态。岩样制备及试验系统如图1所示,其中α为裂纹倾角。

图1 岩样制备及试验系统

Fig.1 Rock sample preparation and test system

2 试验结果分析

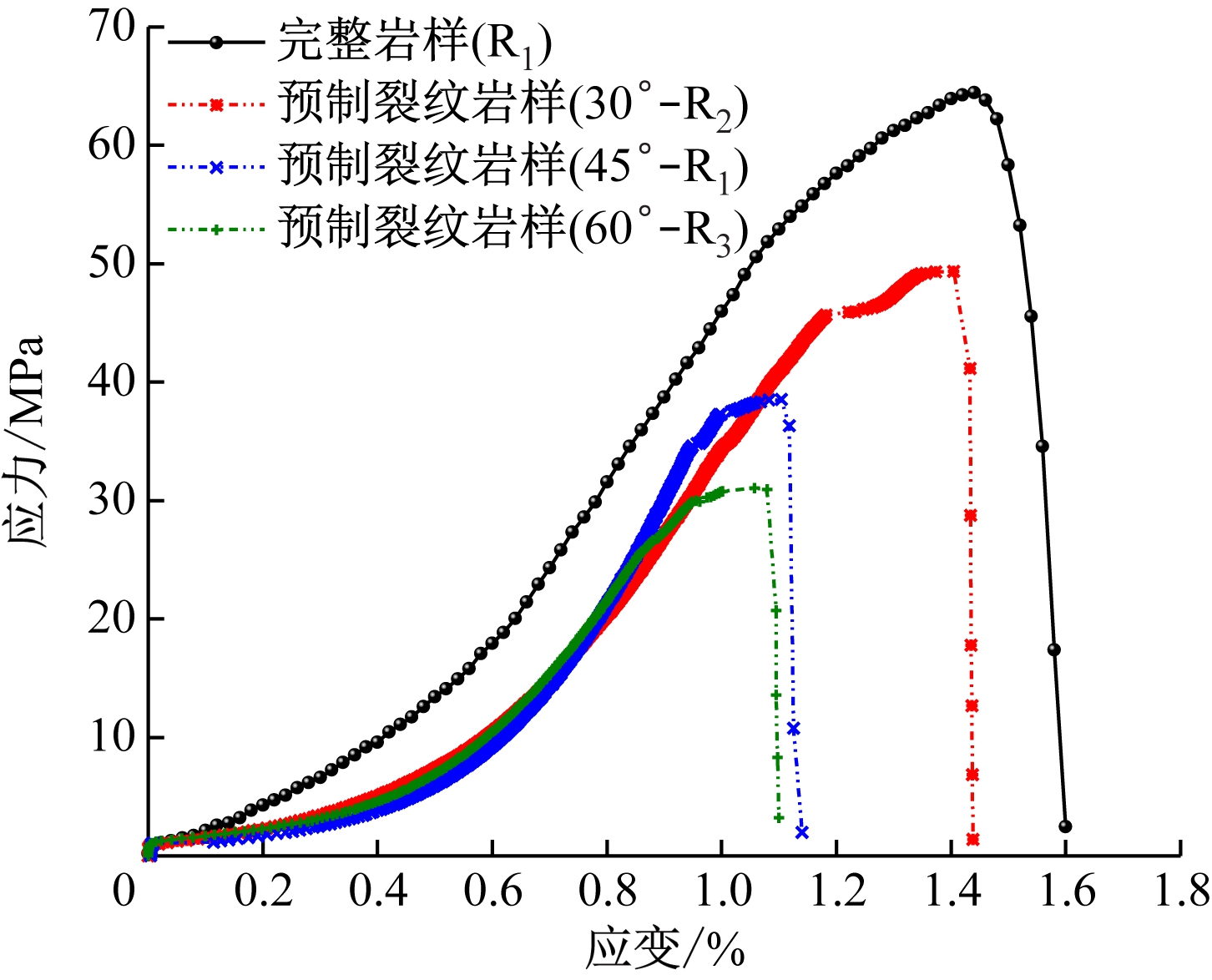

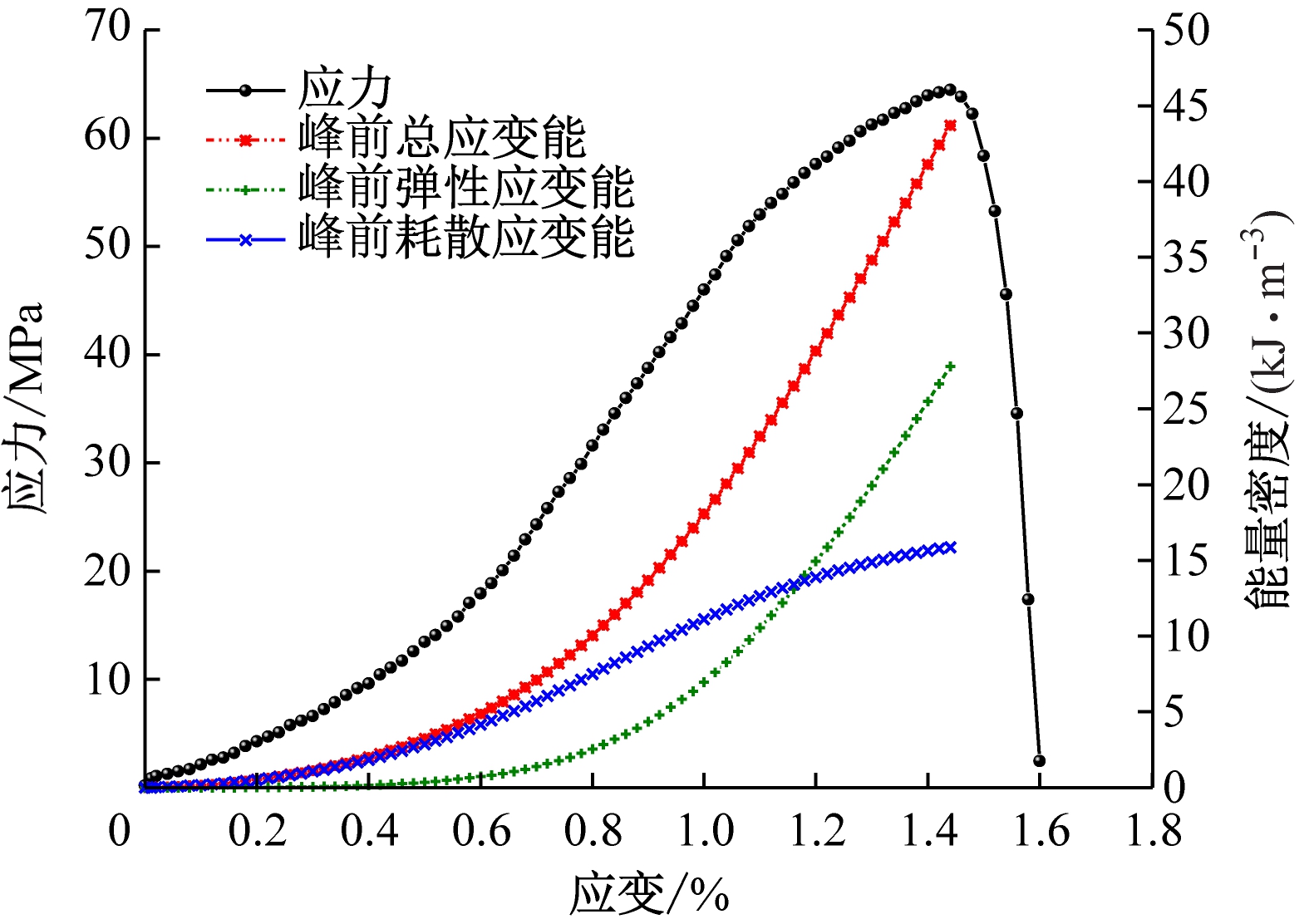

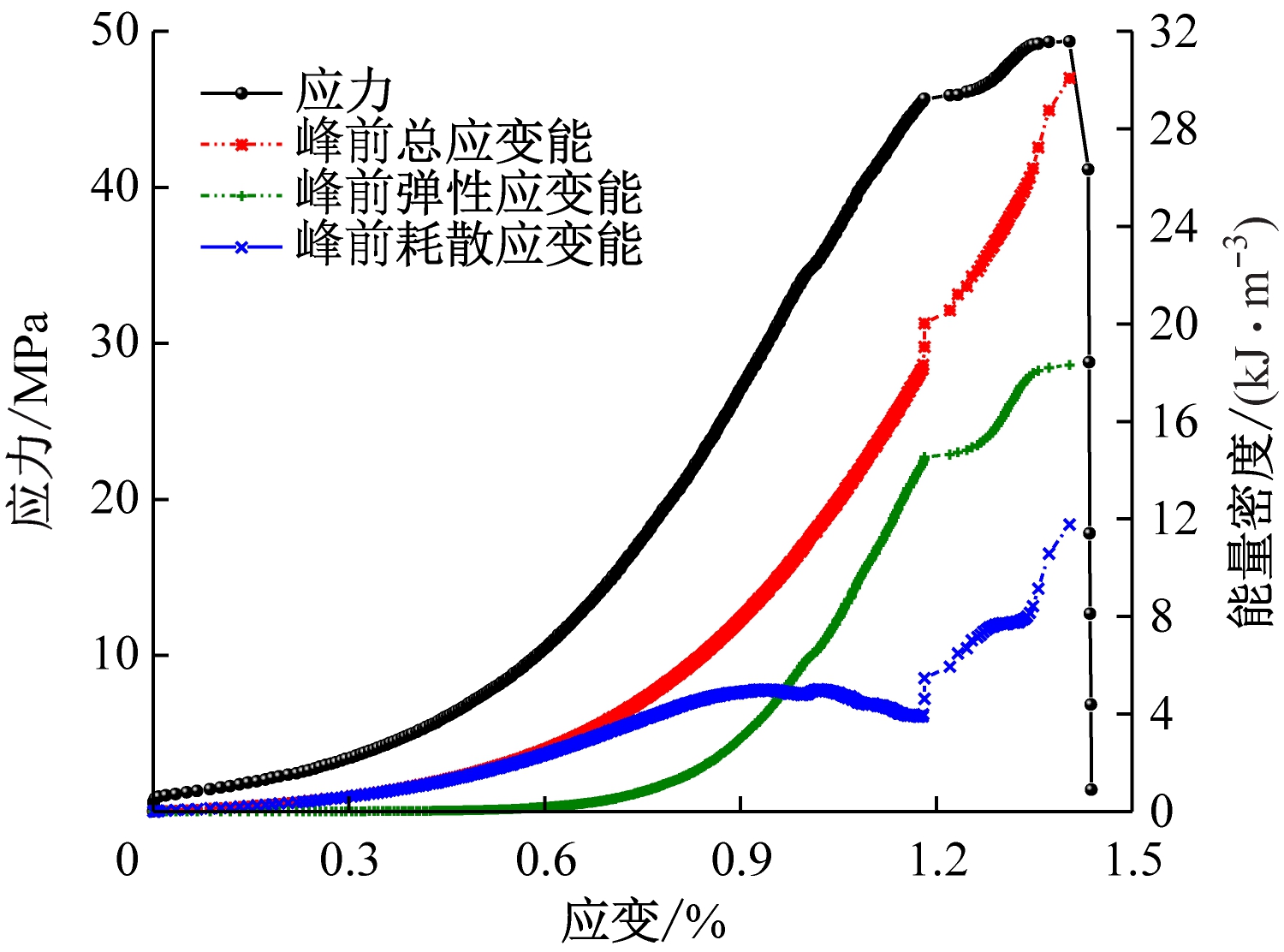

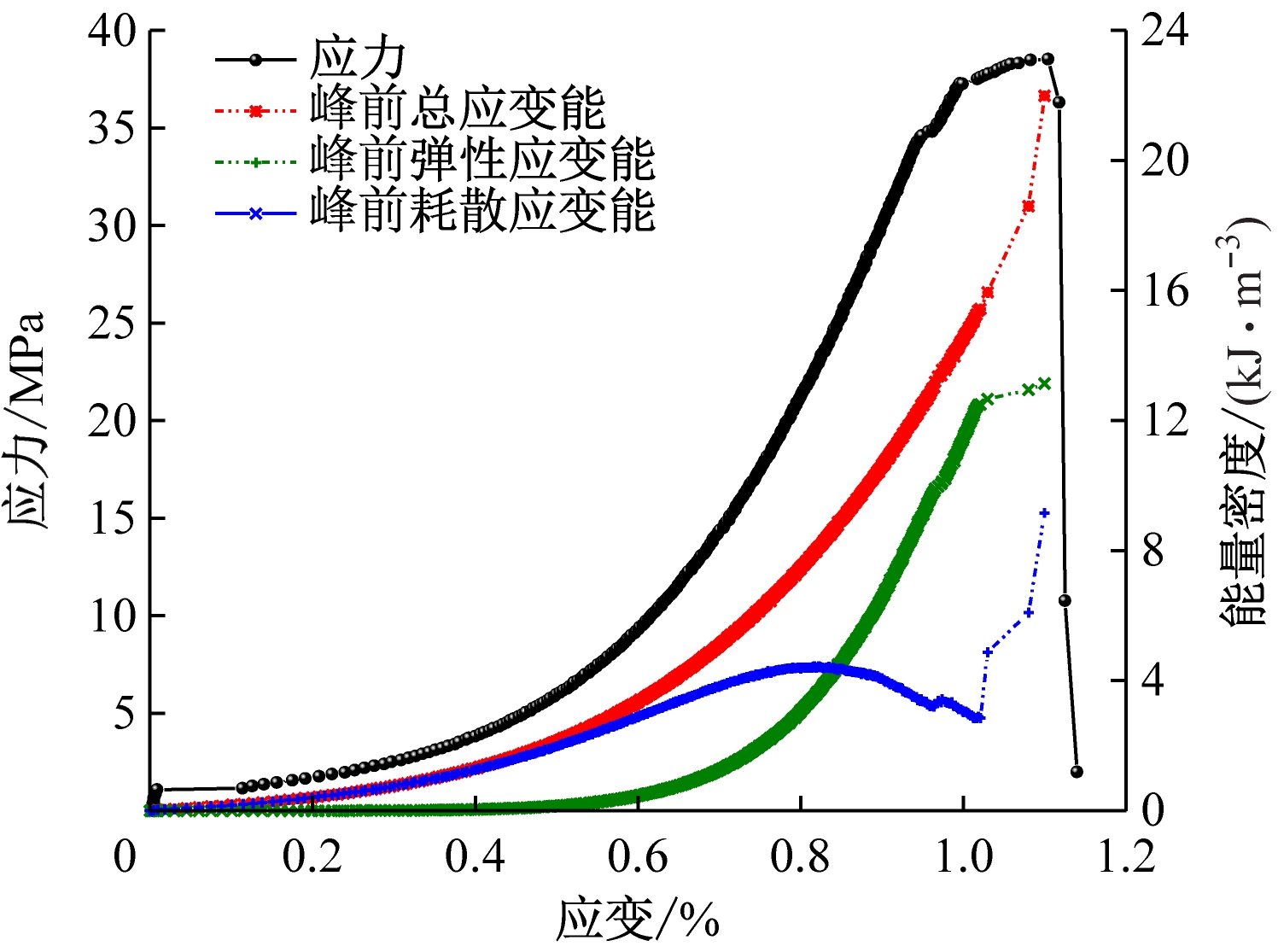

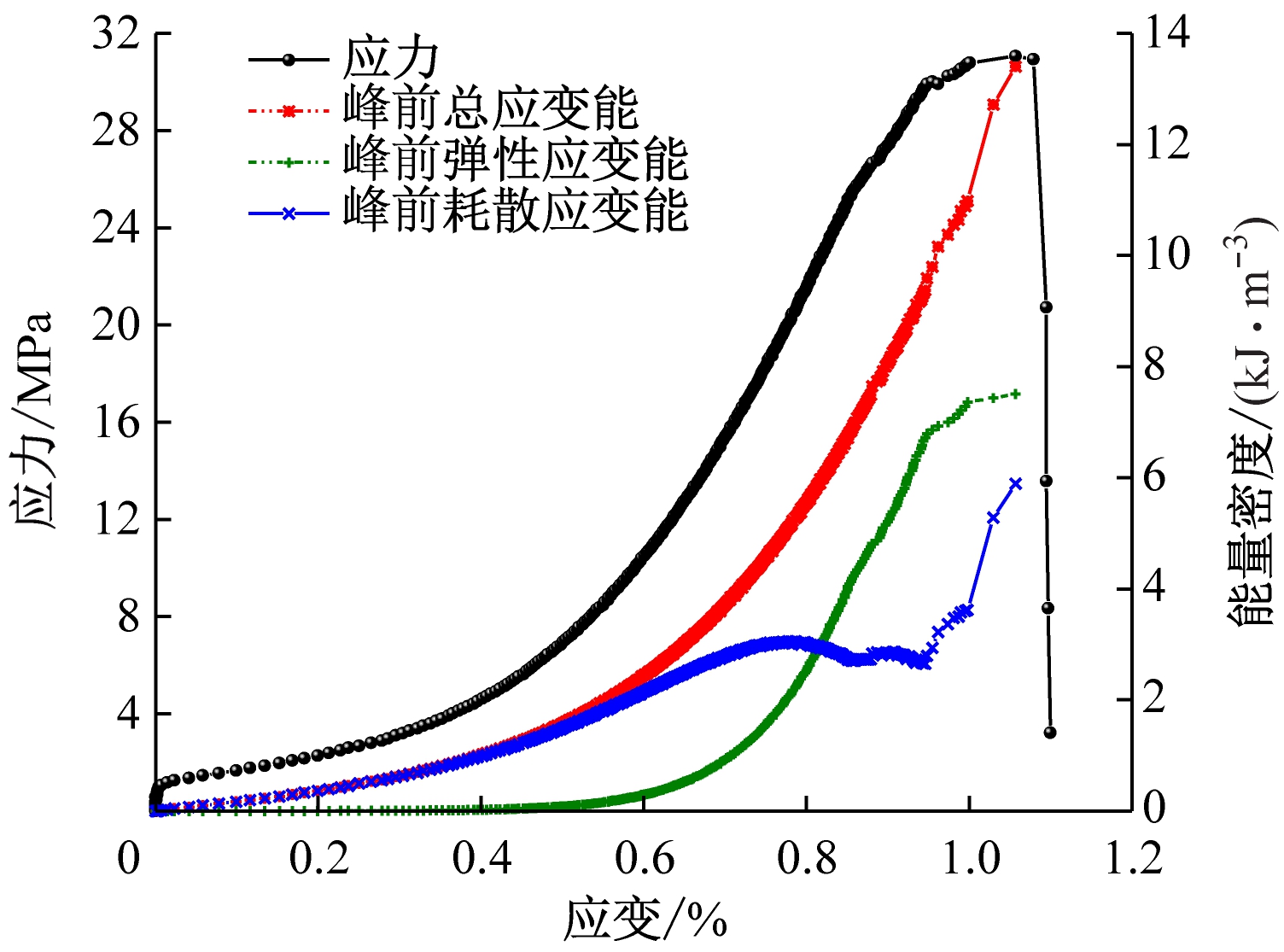

典型的完整岩样及预制裂纹岩样的应力-应变曲线如图2所示。由图2可知,典型的完整岩样及预制裂纹岩样的应力-应变曲线具有相似的变化趋势。完整岩样及预制裂纹岩样30°-R2,45°-R1,60°-R3的抗压强度峰值分别为64.45,49.35,38.53,30.94 MPa,峰值应变分别为1.6%,1.44%,1.14%,1.1%。随着预制裂纹倾角增大,岩样峰值强度降低,峰值应变减小,完整岩样及预制裂纹岩样应力-应变曲线有整体左移压缩趋势。

图2 岩样应力-应变曲线

Fig.2 Stress-strain curves of rock samples

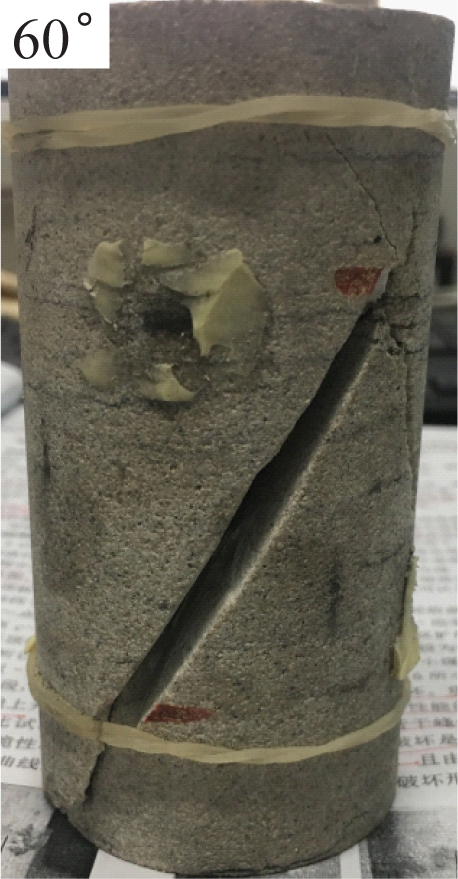

岩样宏观破裂形态如图3所示。随预制裂纹倾角增大,压力机对岩样施加的轴向载荷在预制裂纹倾向的分力增大。在较强的剪切应力作用下,预制裂纹尖端原生裂纹扩展,新生裂纹启裂,继而岩样发生整体破坏,降低了岩样的峰值强度与峰值应变,宏观表现为岩样应变脆性破坏逐渐增强,试件由拉伸劈裂破坏向剪切滑移破坏转变。

图3 岩样宏观破裂形态

Fig.3 Macroscopic crack patterns of rock samples

3 岩样能量演化规律

3.1 理论基础

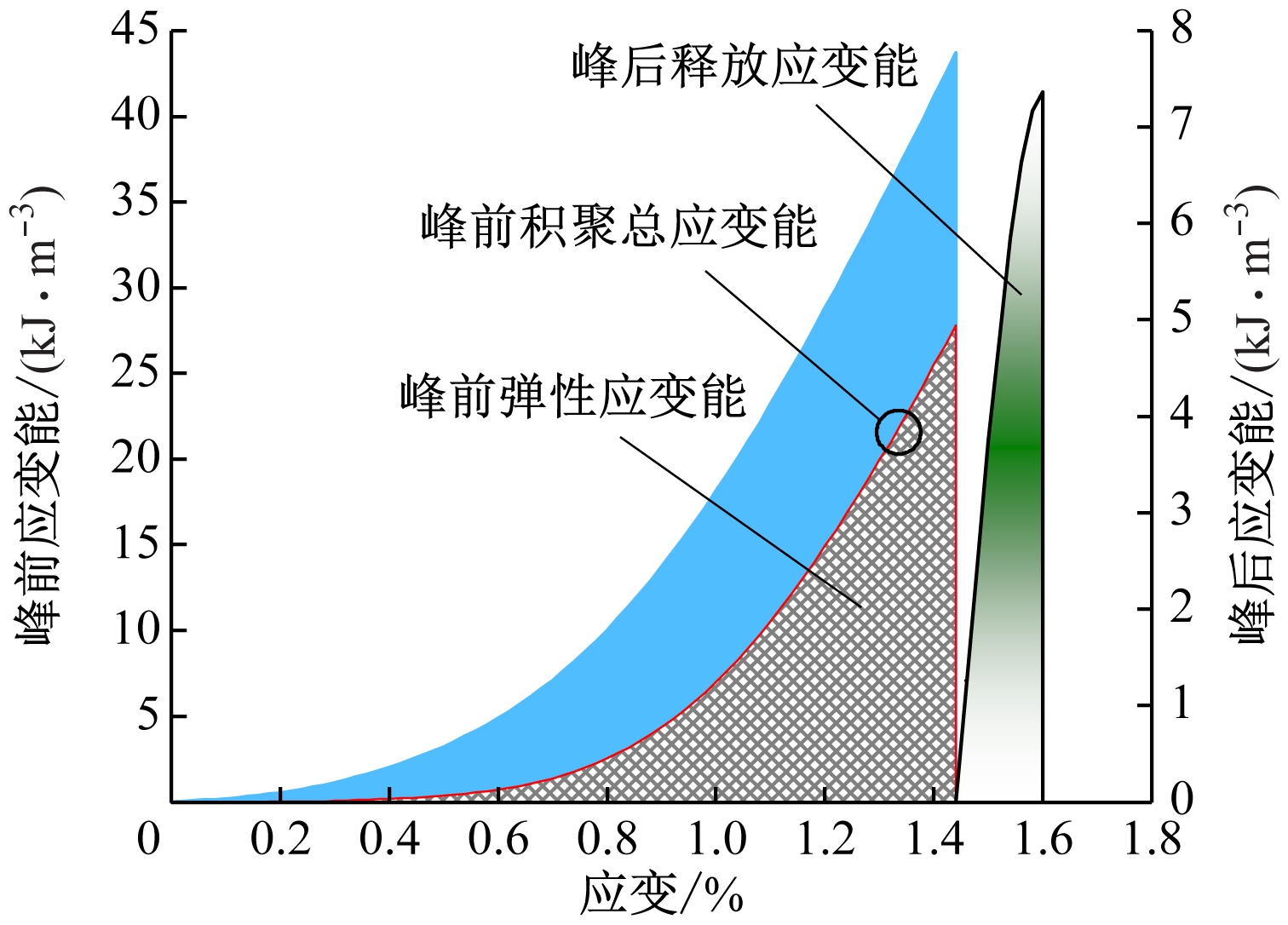

以典型的完整岩样为例,基于微积分思想,说明峰前应变能与峰后应变能的计算思路。

压力机与岩样间存在能量转化,假设两者间的能量转化不与外界发生热交换,根据热力学第一定律[12]可得

U0=Ue+Ud

(1)

式中:U0为压力机加载过程中岩样峰前积聚的总应变能,kJ/m3;Ue为岩样峰前积聚的弹性应变能,kJ/m3;Ud为岩样峰前破裂所释放的耗散应变能,kJ/m3。

应变能计算方法如图4所示。对采集的应变数据ε进行微分,设dε对应的应力为微分区间两端点压力σi(i=1,2,…)和σi+1的平均值,将应力与微分应变相乘,得到微元矩形的面积,对微元矩形进行积分得到峰前总应变能U0[13-14]:

(2)

式中ε1为峰值应力处的应变,%。

图4 应变能计算方法

Fig.4 Strain energy calculation method

由单轴压缩一次加卸载曲线可知,峰值前卸载路径与加载曲线斜率基本一致,由胡克定律[15]可得Ue:

(3)

式中:σc为峰值强度,MPa;εe为峰前弹性应变,%;E0为初始弹性模量,MPa。

将式(2)和式(3)代入式(1)可得Ud:

(4)

峰后释放应变能Uf为应力从ε1至ε2的包络面积,其计算公式为

(5)

式中ε2为峰值应变,%。

峰前弹性应变能Ue一部分转化为峰后释放应变能Uf,一部分转化为盈余应变能Uy。盈余应变能可转化为岩样弹射动能,继而诱发动力灾害。结合式(3)和式(5)可得Uy:

(6)

基于上述计算思路获得典型完整岩样的峰前总应变能、峰前弹性应变能、峰前耗散应变能、峰后释放应变能和盈余应变能,如图5所示。

3.2 峰前应变能转化特征

典型完整岩样及预制裂纹岩样的应力、峰前应变能与应变的关系如图6所示。岩样受荷变形破坏实质是一个压力机能量输入、岩样内部弹性应变能积聚、岩样破坏耗散应变能释放的演化过程,岩样在能量驱动下引发损伤直至宏观失稳破坏。完整岩样及预制裂纹岩样总应变能持续上升,峰前弹性应变能曲线与应力-应变曲线相当,完整岩样耗散应变能呈现缓慢上升趋势,预制裂纹岩样峰前耗散应变能先缓慢上升,再出现显著下降趋势,最后急速上升。

图5 典型的完整岩样能量转化过程

Fig.5 Typical energy conversion process of

intact rock sample

(a) 完整岩样

(b) 30°预制裂纹岩样

(c) 45°预制裂纹岩样

(d) 60°预制裂纹岩样

图6 岩样应力、峰前应变能与应变关系曲线

Fig.6 Relationship curves of stress, pre-peak strain energy and strain of rock samples

对应应力-应变曲线峰前的各阶段,完整岩样及预制裂纹岩样的峰前应变能表现出相应的变化特点。压密阶段:完整岩样及预制裂纹岩样耗散应变能均随岩样变形增加而非线性增大,且大于岩样积聚的弹性应变能,原因在于岩样内部原生裂纹发育,岩样吸收的能量被原生裂纹演化(原生裂纹闭合)所消耗。弹性阶段:随着原生裂纹闭合,完整岩样及预制裂纹岩样弹性应变能缓慢上升,其与耗散应变能相等后(曲线交叉),预制裂纹岩样弹性应变能增速加快,耗散应变能出现下降拐点,而完整岩样弹性应变能与耗散应变能均稳定上升,原因在于预制裂纹改变了岩样内部均一的受力环境,预制裂纹尖端更易储存弹性应变能,尖端产生应力集中现象,而在此阶段总应变能增速恒定,所以耗散应变能出现下降。塑性阶段:当预制裂纹岩样尖端积聚的弹性应变能大于裂纹发育所需表面自由能时,尖端原生裂纹扩展,新生裂纹萌生,耗散应变能出现上升拐点,随着预制裂纹尖端原生裂纹与新生裂纹进一步扩展,储存在岩样内部的弹性应变能开始消耗,耗散应变能骤升。

3.3 预制裂纹倾角对能量密度的影响

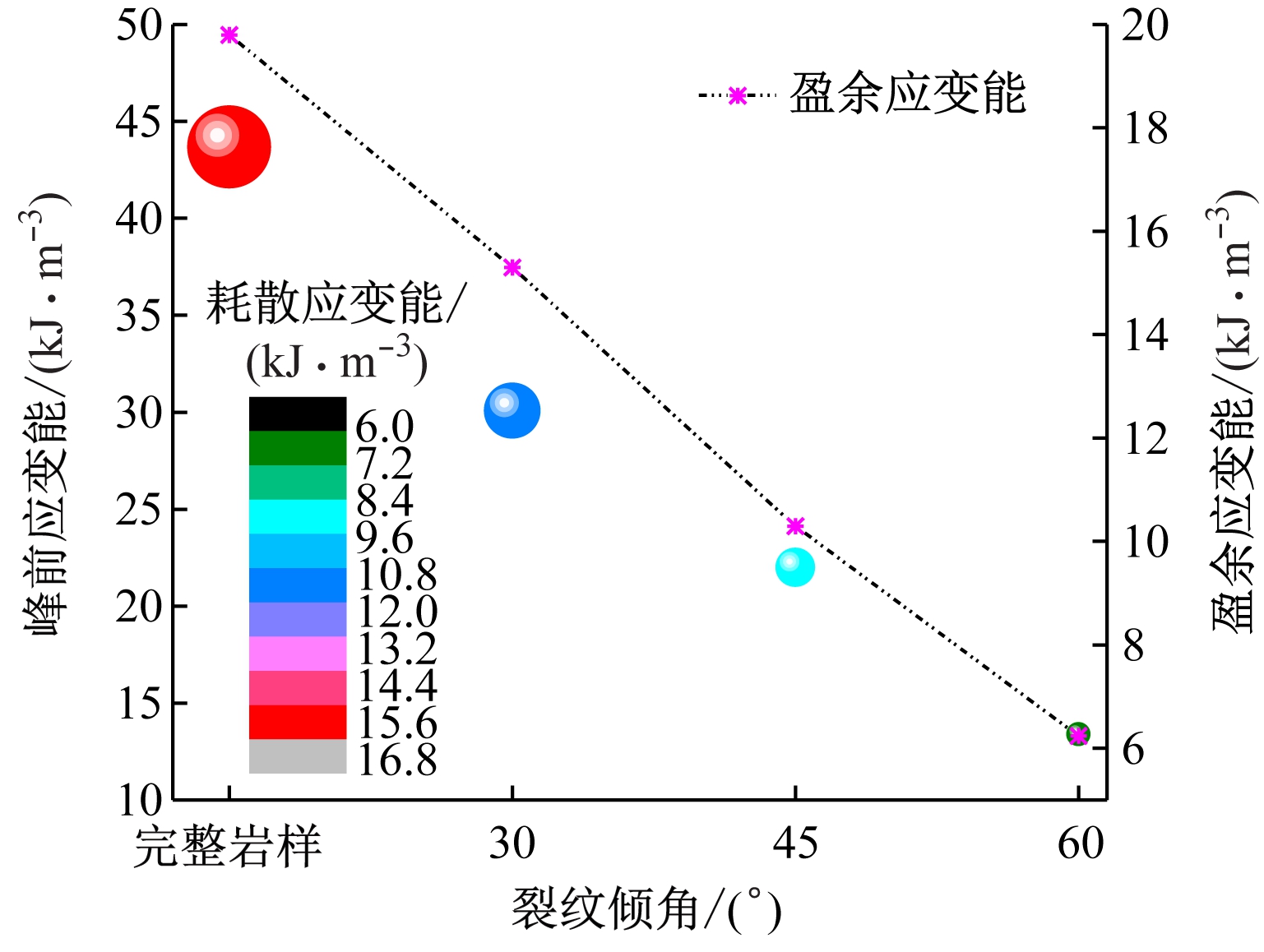

岩样应变能与预制裂纹倾角关系曲线如图7所示。

(a) 应变能峰值

(b) 应变能占比

图7 岩样应变能与预制裂纹倾角关系曲线

Fig.7 Relationship curves between strain energy of

rock sample and pre-cracked inclination

图7(a)中,球体中心纵坐标对应峰前总应变能峰值,球体大小对应峰前弹性应变能峰值,球体颜色对应峰前耗散应变能峰值。可知,随着预制裂纹倾角增大,各应变能峰值减小。完整岩样及裂纹角度为30,45,60°的预制裂纹岩样的总应变能峰值分别为43.68,30.07,21.99,13.39 kJ/m3。与完整岩样相比,裂纹角度为30,45,60°的预制裂纹岩样总应变能峰值的降幅分别为31.16%,49.66%,69.34%,随预制裂纹倾角增大,总应变能峰值降幅较大。完整岩样及裂纹角度为30,45,60°的预制裂纹岩样的峰前弹性应变能峰值分别为27.81,18.31,13.14,7.51 kJ/m3。与完整岩样相比,裂纹角度为30,45,60°的预制裂纹岩样弹性应变能峰值的降幅分别为34.16%,52.75%,73.00%,与总应变能峰值降幅相当,说明预制裂纹对岩样各应变能峰值影响显著。原因在于预制裂纹尖端更易储存弹性应变能,尖端产生应力集中现象,随着预制裂纹倾角增大,岩样承受相同轴向载荷,沿预制裂纹倾向的剪切应力集中程度增强,且预制裂纹尺寸较大,岩样初始损伤增强,尖端新生裂纹发育,最终导致岩样储存弹性应变能的能力减弱,岩样总应变能峰值逐渐减小。

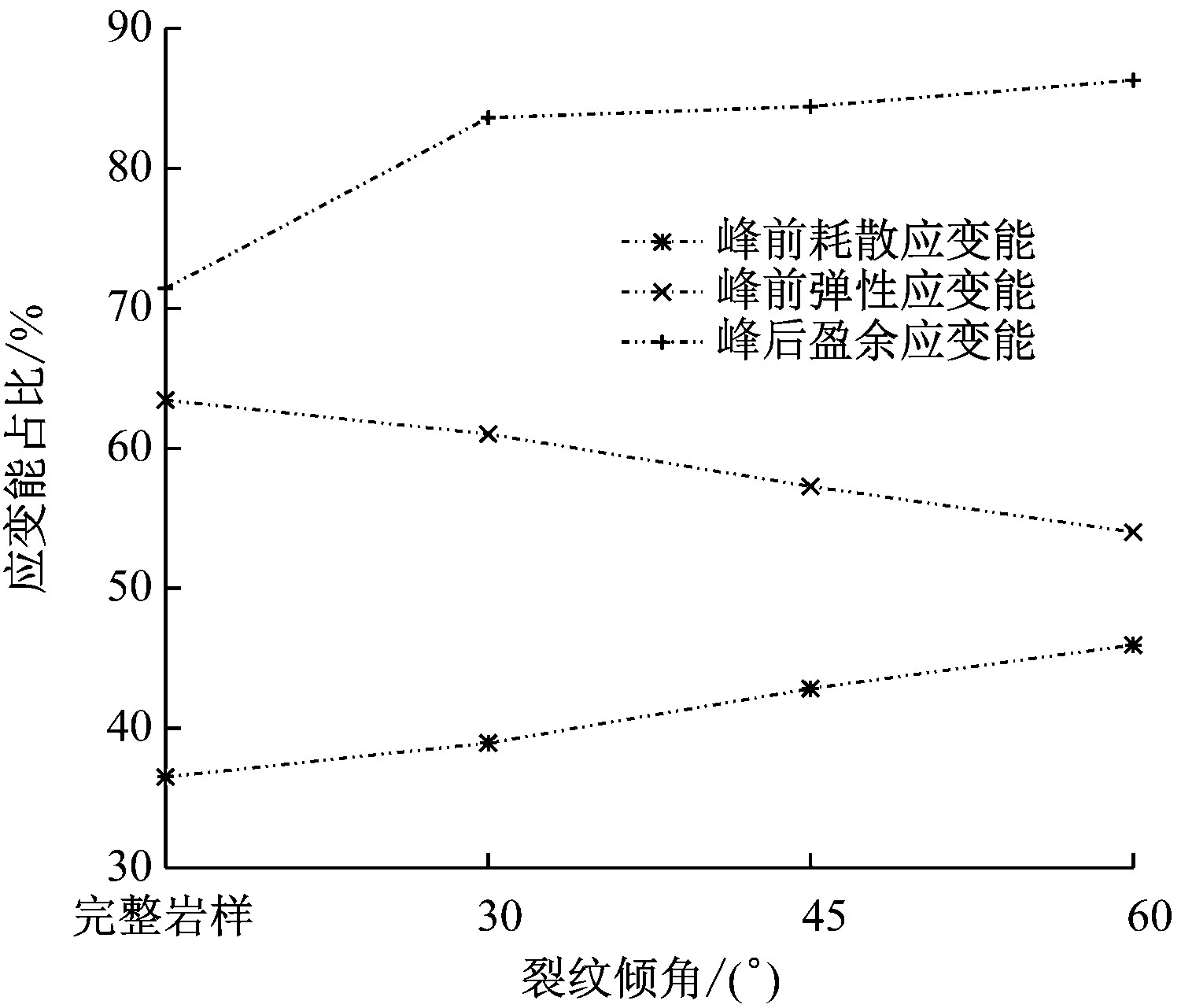

由图7(b)可知,完整岩样及裂纹角度为30,45,60°的预制裂纹岩样的峰前弹性应变能峰值占比分别为63.67%,60.89%,59.75%,56.09%,峰前耗散应变能占比分别为36.33%,39.11%,40.25%,43.91%。对比分析可知,弹性应变能峰值远大于耗散应变能峰值,说明峰前输入岩样的总应变能主要以弹性应变能的形式储存在岩样内部,而能量耗散相对较小。

峰前耗散应变能主要用于岩样内部原生裂纹与新生裂纹的演化及损伤的积累。随着预制裂纹倾角增大,弹性应变能峰值占比减小,耗散应变能峰值占比增大,说明预制裂纹倾角越大,预制裂纹尖端周围的损伤积累越高,裂纹发育,岩样更易破坏。盈余应变能主要用于岩样弹射破坏,随着预制裂纹倾角增大,盈余应变能峰值减小,而盈余应变能峰值占比增大。原因在于预制裂纹倾角越大,岩样的应变脆性破坏越强,峰后释放应变能减小,继而预制裂纹尖端积聚的弹性应变能大量转化为盈余应变能,即岩样破坏时的动能增强,剥落的岩样碎块弹射严重,发出爆鸣声。

当预制裂纹倾角增大时,峰前耗散应变能峰值占比增大,岩样更易破坏,而盈余应变能峰值占比增大,岩样更易弹射破坏。

4 结论

(1) 由于预制裂纹的存在,岩样弹性阶段出现了加速储能期,塑性阶段出现了能量急剧耗散期,岩样耗散应变能占比与盈余应变能占比均随预制裂纹倾角增大而增大,说明岩样发生动力弹射破坏能力增强,岩样破碎,而完整岩样能量上升速率较为平缓。

(2) 针对完整岩样及预制裂纹岩样能量耗散机制,在实际工程实践中应加强大尺度与大倾角缺陷(断层、节理等地质构造)的探测工作,不仅要防治缺陷周边破碎岩体,还要时刻监测缺陷周边弹性应变能(微震信号)变化,采取必要措施,降低岩体结构性冲击危险性。

[1] 袁亮.煤矿粉尘防控与职业安全健康科学构想[J].煤炭学报,2020,45(1):1-7.

YUAN Liang.Scientific conception of coal mine dust control and occupational safety[J].Journal of China Coal Society,2020,45(1):1-7.

[2] 薛霆虓,傅容珊,陈宇卫,等.大尺度断层活动性数值模拟及地震学类比[J].地球物理学进展,2009,24(5):1616-1626.

XUE Tingxiao,FU Rongshan,CHEN Yuwei,et al.Numerical simulation of large scale fault activity and it's seismological analogy[J].Progress in Geophysics,2009,24(5):1616-1626.

[3] 于秋鸽,张华兴,邓伟男,等.开采沉陷中不同断层活化模式研究[J].煤炭学报,2019,44(9):2777-2786.

YU Qiuge,ZHANG Huaxing,DENG Weinan,et al.Different fault activation models in mining subsidence[J].Journal of China Coal Society,2019,44(9):2777-2786.

[4] 戴兵,王建波,赵杰,等.不同倾角与裂纹数量对岩石的强度及裂纹扩展规律的影响分析[J].矿业研究与开发,2020,40(1):7-11.

DAI Bing,WANG Jianbo,ZHAO Jie,et al.Influence analysis of different inclination angles and crack number on the rock strength and crack propagation law[J].Mining Research and Development,2020,40(1):7-11.

[5] YANG Shengqi,TIAN Wenling,HUANG Yanhua,et al.An experimental and numerical study on cracking behavior of brittle sandstone containing two non-coplanar fissures under uniaxial compression[J].Rock Mechanics and Rock Engineering,2016,49(4):1497-1515.

[6] 苏海健,靖洪文,赵洪辉,等.纵向裂隙对砂岩力学特性影响试验研究[J].采矿与安全工程学报,2014,31(4):644-649.

SU Haijian,JING Hongwen,ZHAO Honghui,et al.Experimental study on the influence of longitudinal fissure on mechanics characteristic of sandstone[J].Journal of Mining & Safety Engineering,2014,31(4):644-649.

[7] 来兴平,张帅,崔峰,等.含水承载煤岩损伤演化过程能量释放规律及关键孕灾声发射信号拾取[J].岩石力学与工程学报,2020,39(3):433-444.

LAI Xingping,ZHANG Shuai,CUI Feng,et al.Energy release law during the damage evolution of water-bearing coal and rock and pick-up of AE signals of key pregnancy disasters[J].Chinese Journal of Rock Mechanics and Engineering,2020,39(3):433-444.

[8] 蒋景东,陈生水,徐婕,等.不同含水状态下泥岩的力学性质及能量特征[J].煤炭学报,2018,43(8):2217-2224.

JIANG Jingdong,CHEN Shengshui,XU Jie,et al.Mechanical properties and energy characteristics of mudstone under different containing moisture states[J].Journal of China Coal Society,2018,43(8):2217-2224.

[9] 杨磊,高富强,王晓卿,等.煤岩组合体的能量演化规律与破坏机制[J].煤炭学报,2019,44(12):3894-3902.

YANG Lei,GAO Fuqiang,WANG Xiaoqing,et al.Energy evolution law and failure mechanism of coal-rock combined specimen[J].Journal of China Coal Society,2019,44(12):3894-3902.

[10] 王桂林,张亮,许明,等.单轴压缩下非贯通节理岩体损伤破坏能量演化机制研究[J].岩土工程学报,2019,41(4):639-647.

WANG Guilin,ZHANG Liang,XU Ming,et al.Energy damage evolution mechanism of non-across jointed rock mass under uniaxial compression[J].Chinese Journal of Geotechnical Engineering,2019,41(4):639-647.

[11] 许江,严召松,彭守建,等.岩石渐进性破坏过程中变形和能量分析[J].矿业研究与开发,2019,39(8):47-53.

XU Jiang,YAN Zhaosong,PENG Shoujian,et al.Deformation and energy analysis in progressive failure of rock[J].Mining Research and Development,2019,39(8):47-53.

[12] SOLECKI R,CONANT R J.Advanced mechanics of materials[M].London:Oxford University Press,2003.

[13] 刘刚,肖福坤,秦涛.小尺寸效应下岩石力学特性及声发射规律[J].岩石力学与工程学报,2018,37(增刊2):3905-3917.

LIU Gang,XIAO Fukun,QIN Tao.Rock mechanics characteristics and acoustic emission rule under small-size effect[J].Chinese Journal of Rock Mechanics and Engineering,2018,37(S2):3905-3917.

[14] 刘刚,李英明,肖福坤,等.单、三轴及孔隙水作用下黄砂岩破坏力学行为及损伤演化规律研究[J].岩石力学与工程学报,2019,38(增刊2):3532-3544.

LIU Gang,LI Yingming,XIAO Fukun,et al.Study on failure mechanics behavior and damage evolution law of yellow sandstone under uniaxial triaxial and pore water action[J].Chinese Journal of Rock Mechanics and Engineering,2019,38(S2):3532-3544.

[15] 张黎明,高速,王在泉,等.大理岩加卸荷破坏过程的能量演化特征分析[J].岩石力学与工程学报,2013,32(8):1572-1578.

ZHANG Liming,GAO Su,WANG Zaiquan,et al.Analysis of marble failure energy evolution under loading and unloading conditions[J].Chinese Journal of Rock Mechanics and Engineering,2013,32(8):1572-1578.