Development path of new generation intelligent coal mine under HCPS theory system

-

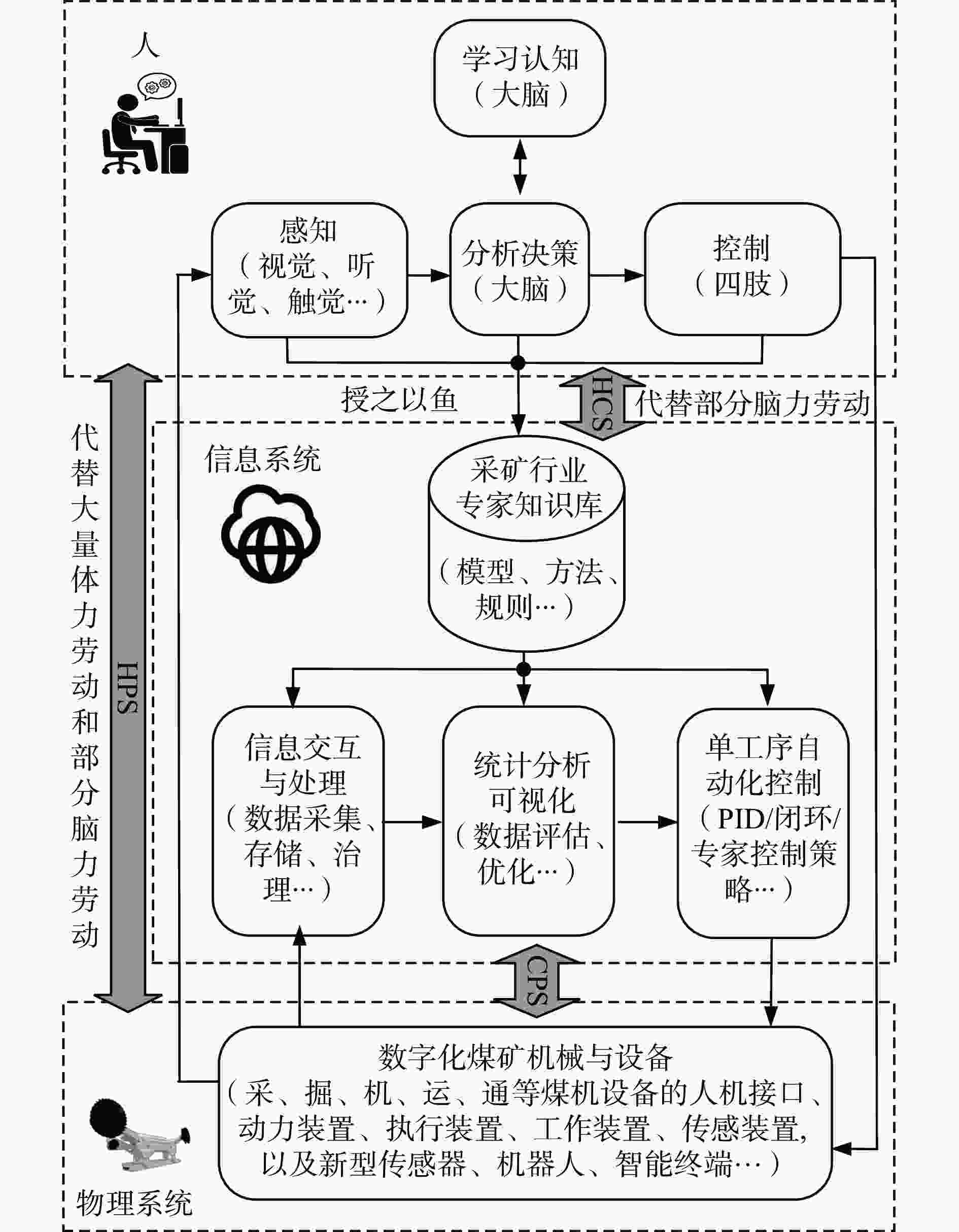

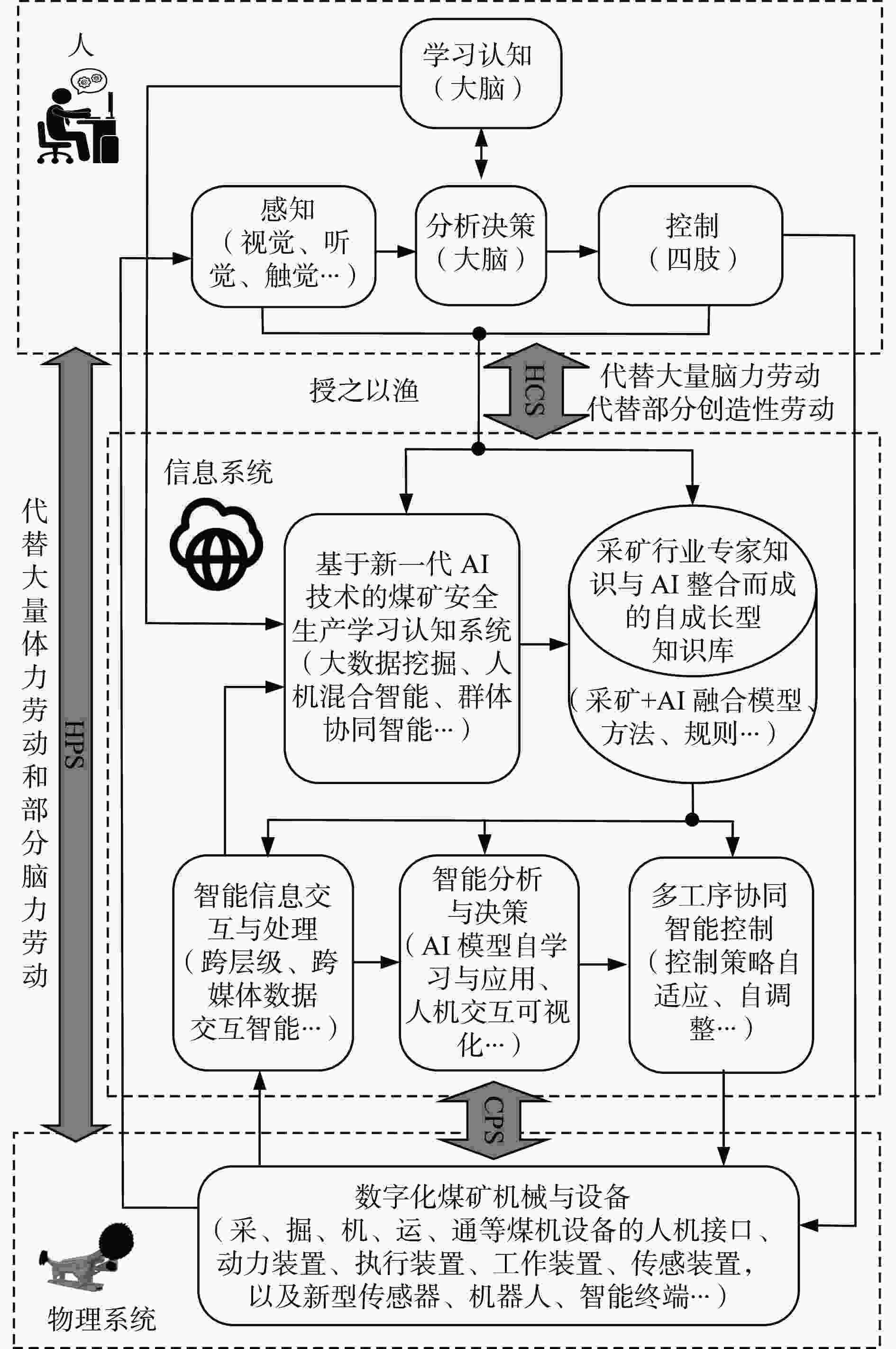

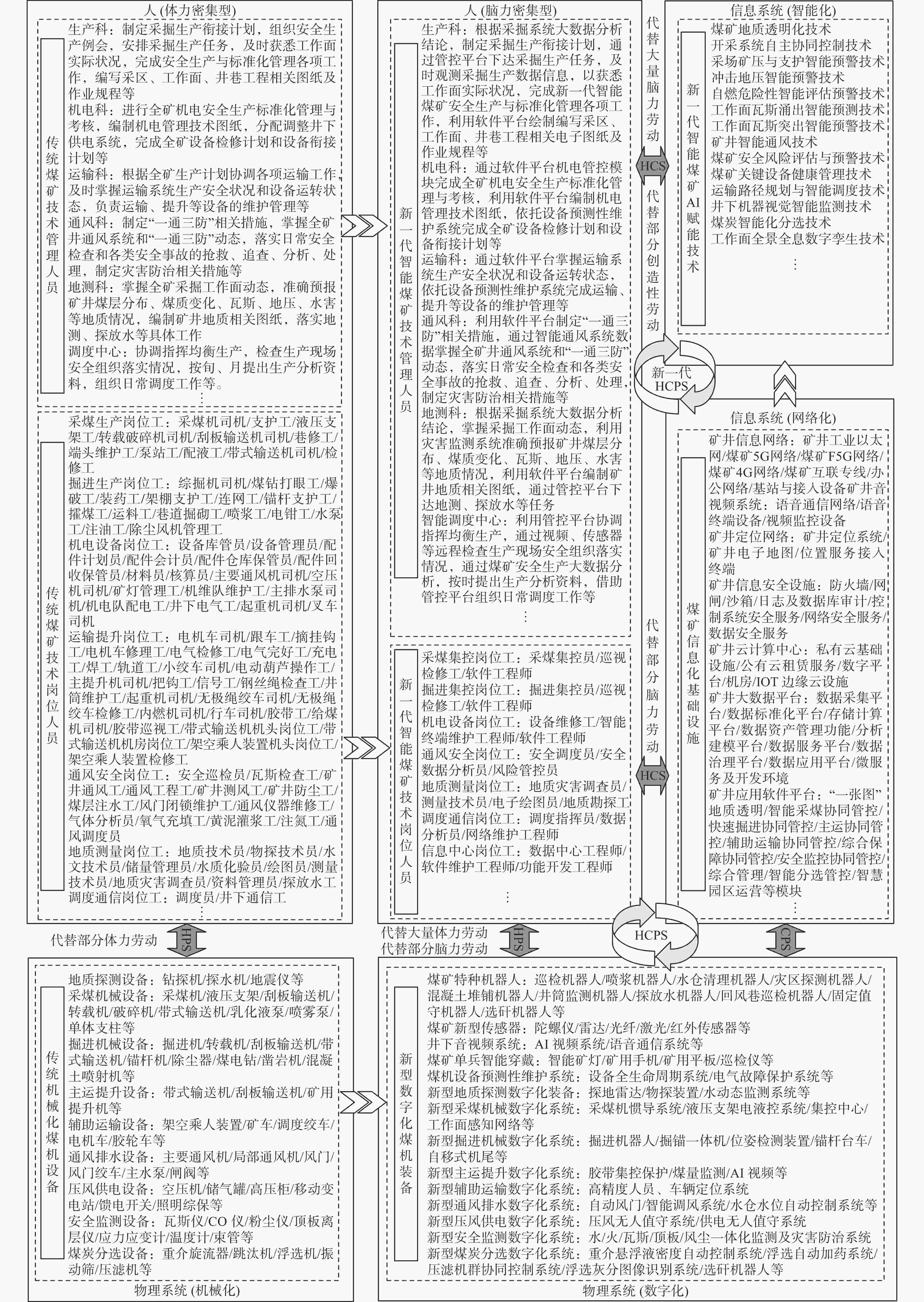

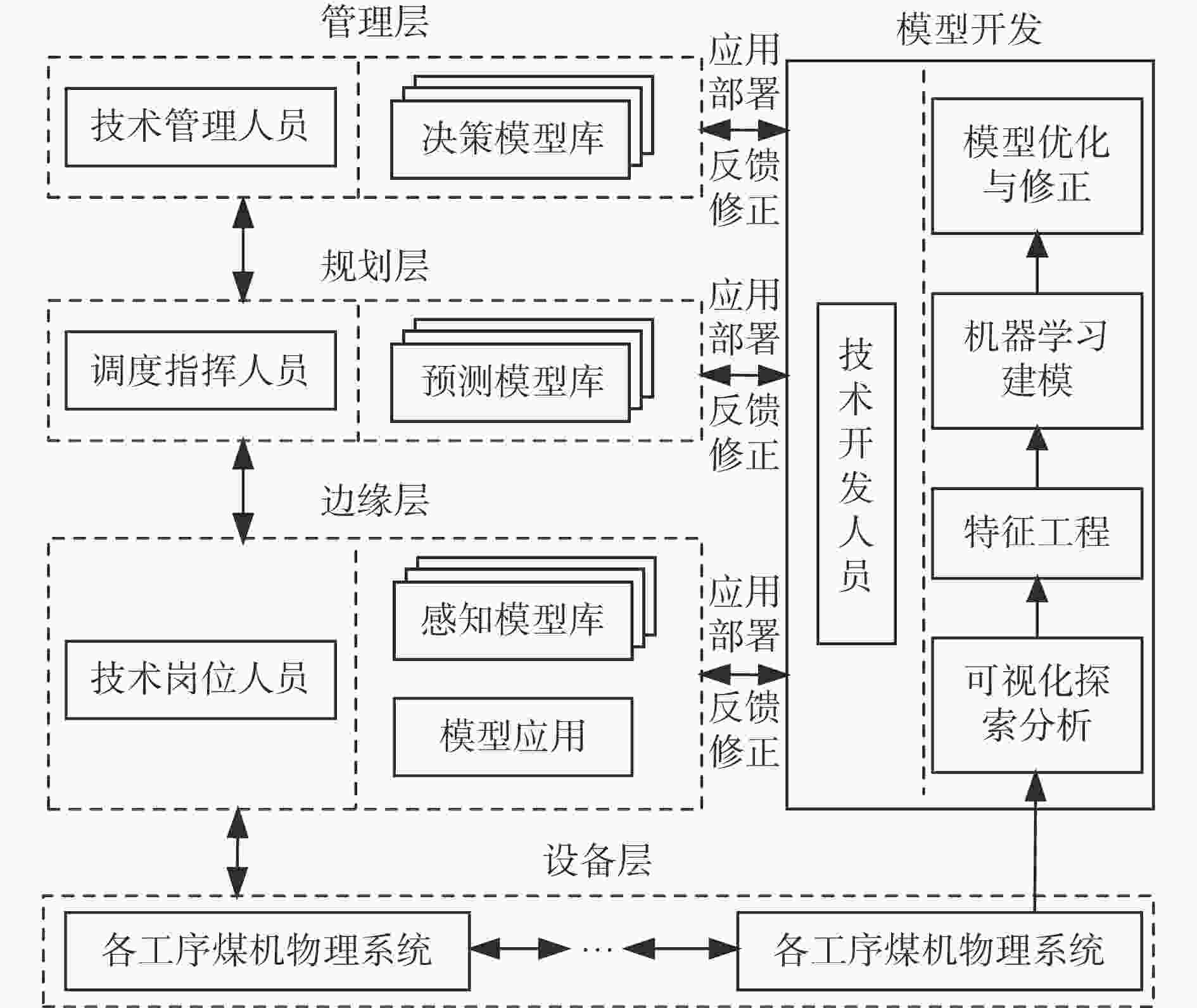

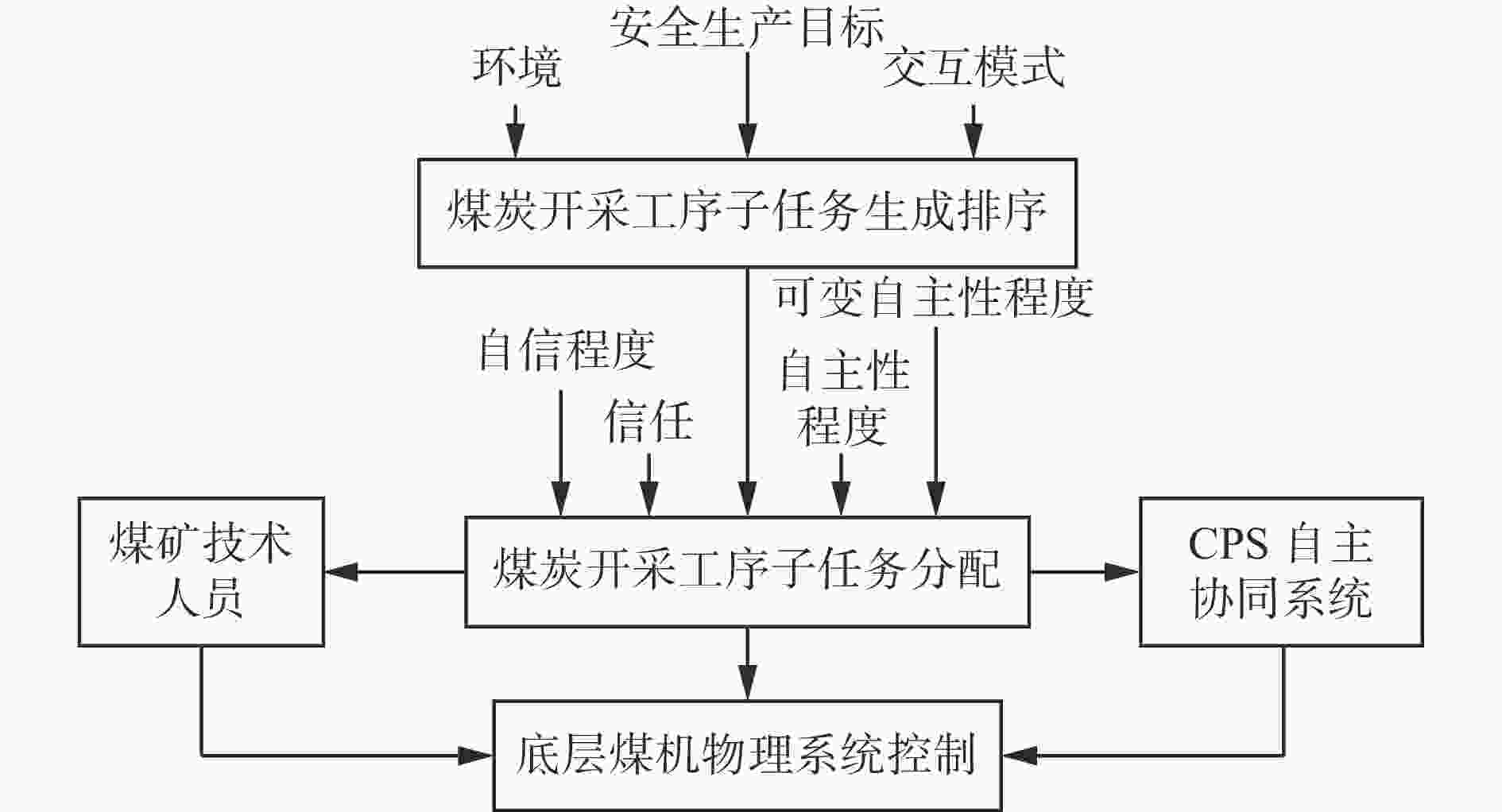

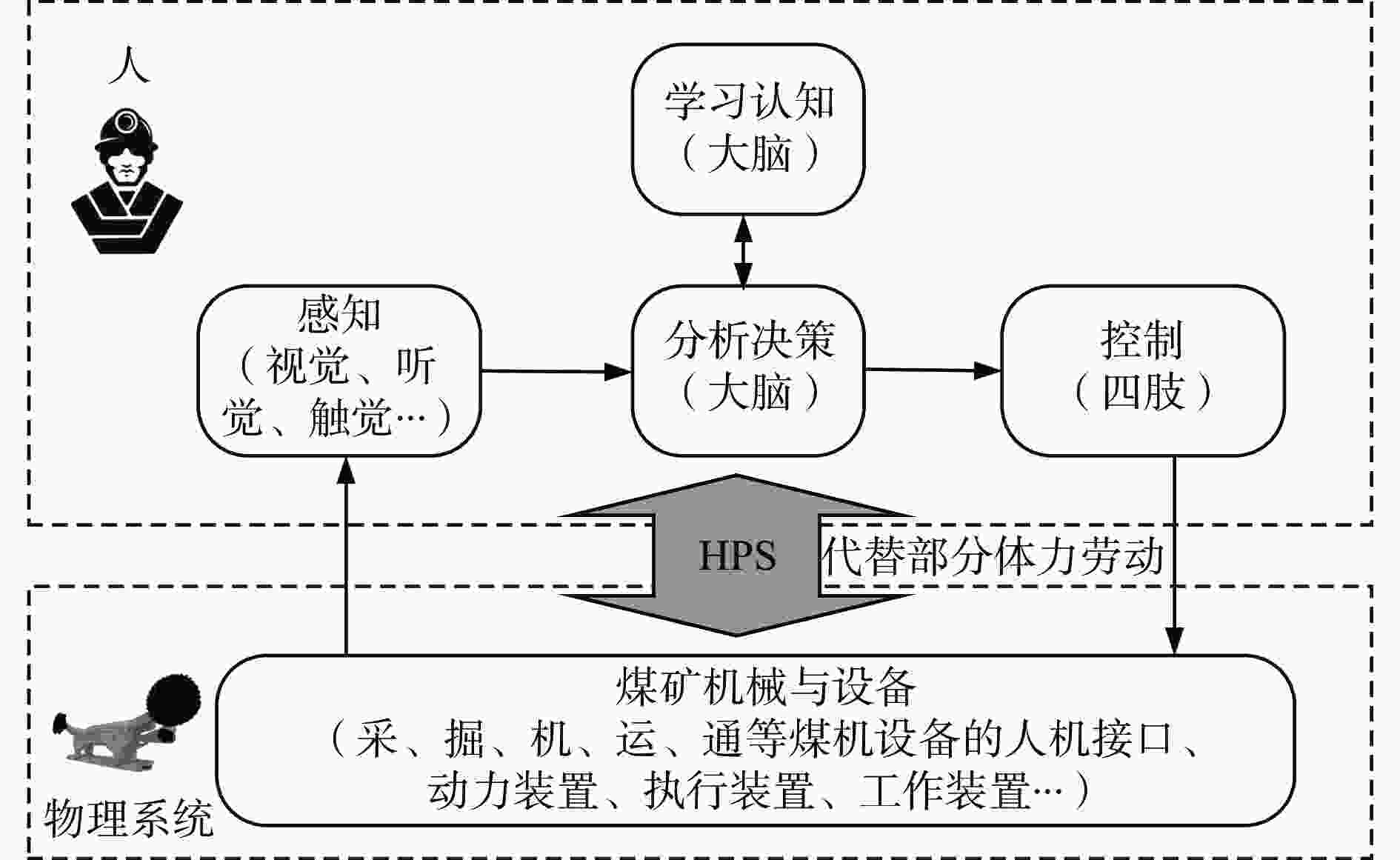

摘要: 在当前煤矿智能化高质量工业发展背景下,基于新一代智能制造“人−信息−物理系统”(HCPS)技术机理,提出了以人为核心的新一代智能煤矿理论体系和技术路径。通过介绍近代煤矿机械化−信息化−智能化的生产模式演进和人、信息系统、物理系统的技术发展,以及新一代智能煤矿发展过程中主要面临的关键场景技术,构建了新一代智能煤矿的HCPS技术体系,阐述了人、煤矿信息系统、煤机装备物理系统相互协同作用机制,并从人、煤矿信息系统、煤机装备物理系统及三者集成这4个维度给出了HCPS技术组成要素。根据以人为核心的发展理念,提出了新一代智能煤矿HCPS理论体系下人机协同技术路径,重点阐明了煤矿安全生产目标下人机自主协同交互模式、人在回路的煤矿安全生产态势感知、人机信任与交互模式下的煤矿系统控制共享、煤矿任务场景的人机信息交互可视化应用开发等核心技术。指出采矿、机械、信息、计算机、管理等多学科交叉人才培养与实践,煤矿管理创新、安全制度创新、生产模式创新、人员工种创新等,是新一代智能煤矿发展的2个关键点。Abstract: Under the background of the current development of the intelligent high-quality coal mine industry, based on the technical mechanism of "human-cyber-physical system"(HCPS) of new generation intelligent manufacturing , the theoretical system and technical path of the new generation intelligent coal mine with human as the center are proposed. By introducing the evolution of modern coal mine mechanization, informatization and intelligent production mode and the technical development of human, cyber system and physical system, as well as the key scene technologies faced by the development process of the new generation intelligent coal mine, the HCPS technical system of the new generation intelligent coal mine is constructed. The interaction mechanism of human, coal mine cyber system and coal machine equipment physical system is expounded. The HCPS technology elements are given from the four dimensions of human, coal mine cyber system, coal machine equipment physical system and their integration. According to the human-centered development concept, the human-machine cooperation technology path under HCPS theoretical system of the new generation intelligent coal mine is proposed. The core technologies such as human-machine autonomous cooperative interaction mode under the goal of coal mine safety production, situation awareness of coal mine safety production based on man in the loop , coal mine system control sharing under human-machine trust and interaction mode, visualization application development of human-machine information interaction of coal mine task scene are emphatically expounded. It is pointed out that training and practice of the multi-disciplinary talent of mining, machinery, cyber, computer and management, and the innovation of coal mine management, safety system, production mode and personnel type of work are the two key points of the development of the new generation intelligent coal mine.

-

表 1 新一代智能煤矿的HCPS技术组成要素

Table 1. Elements of human-cyber-physical system technology of new generation intelligent coal mine

维度 子维度 具体内容 人 人的角色 煤机设备操作工、机电维修工、信息化维护工、安全监管员、矿山图纸设计者、软件开发者、煤矿组织管理者 人的效用 煤矿安全生产的执行效用、组织效用、维护效用、决策效用、管理效用 组织形式 队级、科级、矿级、集团级、技术服务团队 人才层次 煤矿普通技能工人、专业技术员、技术创新人才、管理创新人才 物理系统 安全类 井下安全避难设施、智能型煤矿人员自救穿戴、智能型瓦斯预抽采系统、智能型防火注氮设施、智能型工作面除尘系统、智能型探水设备、智能通风系统、智能型防爆本安装置、智能型顶板卸压装备、救援机器人 生产类 智能采煤装备群、智能掘进装备群、生产辅助机器人 综合保障类 地质探测系统、智能胶带运输系统、智能提升系统、智能辅助运输系统、智能排水系统、智能供电系统、智能压风系统、煤矿特种机器人 信息系统 感知层 井下安全监测传感器、煤机装备状态传感器、地质类传感器、人员状态传感器、音视频系统、智能终端 传输层 井下物联网交互网关、数据交换机、固定有线网络、无线覆盖网络、广域网 平台层 煤矿云计算设施、专业分类数据标志标准、分布式数据库、分析建模平台、微服务及应用开发环境、客户端、信息运维中心 人工智能模型库 煤矿安全分析模型、安全生产规划模型、矿井数字孪生模型、煤机控制决策模型、人机协同自学习模型、煤矿管理协作模型 软件应用层 地质、采掘、安监、综合保障、选煤、管理、经营等煤矿业务智能管控应用软件 系统集成 系统层级 工作面单元级、采区系统级、整体矿井级、整个集团级 设计开发 “一张图”设计更新、透明地质建模、煤机设备选型、信息基础设施建设、软件平台开发、人机界面设计 运营管理 煤矿多系统综合管控平台、多业务协同管理平台、数据专业分析、设备全生命周期管理、安全监测预警平台、人工智能技术赋能 运行模式 采煤专业人员自主、煤机系统自主、人机协同交互 生命周期 煤炭开采周期、煤炭销售周期、系统服役周期、人员管控周期 表 2 新一代智能煤矿HCPS体系下不同自主程度的人机协同交互模式

Table 2. Human-machine cooperative interaction mode with different autonomy degrees under new generation intelligent coal mine human-cyber-physical system

层级 自主程度[32] 适用的煤矿人机混合系统或行为 1 人类执行所有行为 煤机设备修理、信息化系统维护、矿山设计等 2 自主系统可完全补充人类行为集 巷道拉低修复、喷射混凝土等非标辅助工作等 3 自主系统可提供一组人类行为补充集合 材料搬运机器人、水仓清理机器人、智能地质探测系统等 4 自主系统仅提供建议 安全生产协调规划与综合管控、复杂地质条件生产行为、人员路线规划等 5 自主系统在人类允许下自主执行一个行为 智能采煤系统、智能掘进系统、灾区探测机器人、救援机器人等 6 自主系统在有限时间内人类不否决的情况下自动执行行为 智能煤流运输系统、智能提升系统等 7 自主系统执行一个行为并告知人类 应急救援系统等 8 自主系统执行一个行为并在人类要求时告知 智能通风系统、智能辅助运输系统等 9 自主系统执行一个行为并自主决定是否告知人类 智能供电系统、灾害监测预警系统、巡检机器人、固定值守机器人等 10 自主系统自主执行所有行为 智能排水系统、智能压风系统、智能分选系统等 -

[1] 王国法. 煤矿智能化最新技术进展与问题探讨[J]. 煤炭科学技术,2022,50(1):1-27. doi: 10.13199/j.cnki.cst.2022.01.001WANG Guofa. New technological progress of coal mine intelligence and its problems[J]. Coal Science and Technology,2022,50(1):1-27. doi: 10.13199/j.cnki.cst.2022.01.001 [2] 王国法. 加快煤矿智能化建设 推进煤炭行业高质量发展[J]. 中国煤炭,2021,47(1):2-10. doi: 10.3969/j.issn.1006-530X.2021.01.002WANG Guofa. Speeding up intelligent construction of coal mine and promoting high-quality development of coal industry[J]. China Coal,2021,47(1):2-10. doi: 10.3969/j.issn.1006-530X.2021.01.002 [3] 任怀伟,王国法,赵国瑞,等. 智慧煤矿信息逻辑模型及开采系统决策控制方法[J]. 煤炭学报,2019,44(9):2923-2935.REN Huaiwei,WANG Guofa,ZHAO Guorui,et al. Smart coal mine logic model and decision control method of mining system[J]. Journal of China Coal Society,2019,44(9):2923-2935. [4] 刘峰. 对煤矿智能化发展的认识和思考[J]. 中国煤炭工业,2020(8):5-9. doi: 10.3969/j.issn.1673-9612.2020.08.002LIU Feng. Understanding and thinking of intelligent development of coal mine[J]. China Coal Industry,2020(8):5-9. doi: 10.3969/j.issn.1673-9612.2020.08.002 [5] 张建明,曹文君,王景阳,等. 智能化煤矿信息基础设施标准体系研究[J]. 中国煤炭,2021,47(11):1-6. doi: 10.3969/j.issn.1006-530X.2021.11.001ZHANG Jianming,CAO Wenjun,WANG Jingyang,et al. Research on information infrastructure standard system for intelligent coal mine[J]. China Coal,2021,47(11):1-6. doi: 10.3969/j.issn.1006-530X.2021.11.001 [6] 王国法,徐亚军,张金虎,等. 煤矿智能化开采新进展[J]. 煤炭科学技术,2021,49(1):1-10. doi: 10.13199/j.cnki.cst.2021.01.001WANG Guofa,XU Yajun,ZHANG Jinhu,et al. New development of intelligent mining in coal mines[J]. Coal Science and Technology,2021,49(1):1-10. doi: 10.13199/j.cnki.cst.2021.01.001 [7] 张旭辉,杨文娟,薛旭升,等. 煤矿远程智能掘进面临的挑战与研究进展[J]. 煤炭学报,2022,47(1):579-597. doi: 10.13225/j.cnki.jccs.yg21.1941ZHANG Xuhui,YANG Wenjuan,XUE Xusheng,et al. Challenges and developing of the intelligent remote control on roadheaders in coal mine[J]. Journal of China Coal Society,2022,47(1):579-597. doi: 10.13225/j.cnki.jccs.yg21.1941 [8] 王虹,王步康,张小峰,等. 煤矿智能快掘关键技术与工程实践[J]. 煤炭学报,2021,46(7):2068-2083. doi: 10.13225/j.cnki.jccs.jj21.0412WANG Hong,WANG Bukang,ZHANG Xiaofeng,et al. Key technology and engineering practice of intelligent rapid heading in coal mine[J]. Journal of China Coal Society,2021,46(7):2068-2083. doi: 10.13225/j.cnki.jccs.jj21.0412 [9] 杨健健,葛世荣,王飞跃,等. 平行掘进:基于ACP理论的掘−支−锚智能控制理论与关键技术[J]. 煤炭学报,2021,46(7):2100-2111. doi: 10.13225/j.cnki.jccs.jj21.0679YANG Jianjian,GE Shirong,WANG Feiyue,et al. Parallel tunneling:intelligent control and key technologies for tunneling,supporting and anchoring based on ACP theory[J]. Journal of China Coal Society,2021,46(7):2100-2111. doi: 10.13225/j.cnki.jccs.jj21.0679 [10] 马宏伟,王世斌,毛清华,等. 煤矿巷道智能掘进关键共性技术[J]. 煤炭学报,2021,46(1):310-320. doi: 10.13225/j.cnki.jccs.yg20.1904MA Hongwei,WANG Shibin,MAO Qinghua,et al. Key common technology of intelligent heading in coal mine roadway[J]. Journal of China Coal Society,2021,46(1):310-320. doi: 10.13225/j.cnki.jccs.yg20.1904 [11] 周福宝,魏连江,夏同强,等. 矿井智能通风原理、关键技术及其初步实现[J]. 煤炭学报,2020,45(6):2225-2235. doi: 10.13225/j.cnki.jccs.zn20.0338ZHOU Fubao,WEI Lianjiang,XIA Tongqiang,et al. Principle,key technology and preliminary realization of mine intelligent ventilation[J]. Journal of China Coal Society,2020,45(6):2225-2235. doi: 10.13225/j.cnki.jccs.zn20.0338 [12] 卢新明,尹红. 矿井通风智能化理论与技术[J]. 煤炭学报,2020,45(6):2236-2247. doi: 10.13225/j.cnki.jccs.ZN20.0365LU Xinming,YIN Hong. The intelligent theory and technology of mine ventilation[J]. Journal of China Coal Society,2020,45(6):2236-2247. doi: 10.13225/j.cnki.jccs.ZN20.0365 [13] 周李兵. 煤矿井下无轨胶轮车无人驾驶系统研究[J]. 工矿自动化,2022,48(6):36-48. doi: 10.13272/j.issn.1671-251x.17946ZHOU Libing. Research on unmanned driving system of underground trackless rubber-tyred vehicle in coal mine[J]. Journal of Mine Automation,2022,48(6):36-48. doi: 10.13272/j.issn.1671-251x.17946 [14] 贺海涛,廖志伟,郭卫. 煤矿井下无轨胶轮车无人驾驶技术研究与探索[J]. 煤炭科学技术,2022,50(增刊1):212-217. doi: 10.13199/j.cnki.cst.2022-0594HE Haitao,LIAO Zhiwei,GUO Wei. Research and exploration on driverless technology of trackless rubbertyred vehicle in coal mine[J]. Coal Science and Technology,2022,50(S1):212-217. doi: 10.13199/j.cnki.cst.2022-0594 [15] 陈广达,冯殿义. 煤矿井下无人值守排水泵站自动化控制系统设计[J]. 辽宁工业大学学报(自然科学版),2015,35(2):79-81,86.CHEN Guangda,FENG Dianyi. Design of automation control system in the unattended underground coal mine drainage[J]. Journal of Liaoning University of Technology(Natural Science Edition),2015,35(2):79-81,86. [16] 康宏. 煤矿井下采区变电所无人值守监控系统的应用探究[J]. 能源与节能,2018(2):140-142. doi: 10.3969/j.issn.2095-0802.2018.02.068KANG Hong. Application exploration on unattended monitoring system of electric power substation in underground mining area in coal mine[J]. Energy and Energy Conservation,2018(2):140-142. doi: 10.3969/j.issn.2095-0802.2018.02.068 [17] 毛善君,崔建军,王世斌,等. 煤矿智能开采信息共享管理平台构建研究[J]. 煤炭学报,2020,45(6):1937-1948. doi: 10.13225/j.cnki.jccs.ZN20.0341MAO Shanjun,CUI Jianjun,WANG Shibin,et al. Construction of information sharing platform of mine safe production for intelligent mining[J]. Journal of China Coal Society,2020,45(6):1937-1948. doi: 10.13225/j.cnki.jccs.ZN20.0341 [18] 张晓霞, 陈思宇, 苏上海, 等. 矿井级智能一体化管控平台设计及应用[J/OL]. 煤炭科学技术: 1-9. [2022-05-31]. DOI: 10.13199/j. cnki. cst. 2022-0124.ZHANG Xiaoxia, CHEN Siyu, SU Shanghai, et al. Design and application of intelligent integrated control platform at mine level[J/OL]. Coal Science and Technology: 1-9[2022-05-31]. DOI: 10.13199/j.cnki.cst.2022-0124. [19] 疏礼春. 智能煤矿数据中台架构及关键技术研究[J]. 工矿自动化,2021,47(6):40-44. doi: 10.13272/j.issn.1671-251x.2020120052SHU Lichun. Research on the architecture and key technologies of intelligent coal mine data middle platform[J]. Industry and Mine Automation,2021,47(6):40-44. doi: 10.13272/j.issn.1671-251x.2020120052 [20] 李新华. 以工业互联网推进煤炭产业数字化转型研究与实践[J]. 中国煤炭,2021,47(10):1-5. doi: 10.3969/j.issn.1006-530X.2021.10.001LI Xinhua. Research and practice of promoting digital transformation of coal industry with industrial Internet[J]. China Coal,2021,47(10):1-5. doi: 10.3969/j.issn.1006-530X.2021.10.001 [21] 张建中,郭军. 智慧矿山工业互联网技术架构探讨[J]. 煤炭科学技术,2022,50(5):238-246. doi: 10.13199/j.cnki.cst.ZN20-066ZHANG Jianzhong,GUO Jun. Discussion on industrial Internet technology framework of smart mine[J]. Coal Science and Technology,2022,50(5):238-246. doi: 10.13199/j.cnki.cst.ZN20-066 [22] 李首滨. 基于工业互联网的煤矿智能一体化管控平台[J]. 智能矿山,2022,3(4):2-11.LI Shoubin. Intelligent integrated control platform for coal mine based on industrial Internet[J]. Journal of Intelligent Mine,2022,3(4):2-11. [23] ZHOU Ji,LI Peigen,ZHOU Yanhong,et al. Toward new-generation intelligent manufacturing[J]. Engineering,2018,4(1):11-20. doi: 10.1016/j.eng.2018.01.002 [24] 中国煤炭工业协会. 基于工业互联网的煤炭企业信息化基础设施建设白皮书(2022版)[R]. 北京: 中国煤炭工业协会, 2022.China National Coal Association. White paper on informationization infrastructure construction of coal enterprises based on industrial Internet (2022 edition)[R]. Beijing: China National Coal Association, 2022. [25] 程建远,王保利,范涛,等. 煤矿地质透明化典型应用场景及关键技术[J]. 煤炭科学技术,2022,50(7):1-12. doi: 10.13199/j.cnki.cst.2022-0540CHENG Jianyuan,WANG Baoli,FAN Tao,et al. Typical application scenes and key technologies of coal mine geological transparency[J]. Coal Science and Technology,2022,50(7):1-12. doi: 10.13199/j.cnki.cst.2022-0540 [26] 王国法,刘峰,孟祥军,等. 煤矿智能化(初级阶段)研究与实践[J]. 煤炭科学技术,2019,47(8):1-36. doi: 10.13199/j.cnki.cst.2019.08.001WANG Guofa,LIU Feng,MENG Xiangjun,et al. Research and practice on intelligent coal mine construction(primary stage)[J]. Coal Science and Technology,2019,47(8):1-36. doi: 10.13199/j.cnki.cst.2019.08.001 [27] 潘一山,代连朋. 煤矿冲击地压发生理论公式[J]. 煤炭学报,2021,46(3):789-799. doi: 10.13225/j.cnki.jccs.yt20.1946PAN Yishan,DAI Lianpeng. Theoretical formula of rock burst in coal mines[J]. Journal of China Coal Society,2021,46(3):789-799. doi: 10.13225/j.cnki.jccs.yt20.1946 [28] 李雨成,李俊桥,邓存宝,等. 基于角联子网的风量反演风阻病态改良算法[J]. 煤炭学报,2019,44(4):1147-1153. doi: 10.13225/j.cnki.jccs.2018.0741LI Yucheng,LI Junqiao,DENG Cunbao,et al. Improved algorithm of air quantity calculating resistance based on diagonal subnetwork[J]. Journal of China Coal Society,2019,44(4):1147-1153. doi: 10.13225/j.cnki.jccs.2018.0741 [29] 金智新,王延生,邓存宝,等. 广义安全结构理论研究[J]. 中国安全科学学报,2017,27(5):41-46. doi: 10.16265/j.cnki.issn1003-3033.2017.05.008JIN Zhixin,WANG Yansheng,DENG Cunbao,et al. Research on generalized safety structure theory[J]. China Safety Science Journal,2017,27(5):41-46. doi: 10.16265/j.cnki.issn1003-3033.2017.05.008 [30] 王然风,高建川,付翔. 智能化选煤厂架构及关键技术[J]. 工矿自动化,2019,45(7):28-32. doi: 10.13272/j.issn.1671-251x.17465WANG Ranfeng,GAO Jianchuan,FU Xiang. Framework and key technologies of intelligent coal preparation plant[J]. Industry and Mine Automation,2019,45(7):28-32. doi: 10.13272/j.issn.1671-251x.17465 [31] 葛世荣,王世博,管增伦,等. 数字孪生— —应对智能化综采工作面技术挑战[J]. 工矿自动化,2022,48(7):1-12.GE Shirong,WANG Shibo,GUAN Zenglun,et al. Digital twin:meeting the technical challenges of intelligent fully mechanized working face[J]. Journal of Mine Automation,2022,48(7):1-12. [32] SHERIDAN T B, VERPLANK W L, BROOKS T L. Human and computer control of undersea teleoperators[C]. The 14th Annual Conference on Manual Control, San Francisco, 1978: 1-188. [33] 黄捷,陈宇韬,郑松. 面向集群自主系统的人机混合增强智能研究进展[J]. 福州大学学报(自然科学版),2021,49(5):666-680.HUANG Jie,CHEN Yutao,ZHENG Song. Review on human-machine hybrid intelligence for autonomous system swarms[J]. Journal of Fuzhou University(Natural Science Edition),2021,49(5):666-680. [34] 马小平,杨雪苗,胡延军,等. 人工智能技术在矿山智能化建设中的应用初探[J]. 工矿自动化,2020,46(5):8-14. doi: 10.13272/j.issn.1671-251x.17593MA Xiaoping,YANG Xuemiao,HU Yanjun,et al. Preliminary study on application of artificial intelligence technology in mine intelligent construction[J]. Industry and Mine Automation,2020,46(5):8-14. doi: 10.13272/j.issn.1671-251x.17593 [35] CHEN J Y C,BARNES M J. Human-agent teaming for multirobot control:a review of human factors issues[J]. IEEE Transactions on Human-Machine Systems,2014,44(1):13-29. doi: 10.1109/THMS.2013.2293535 -

下载:

下载: